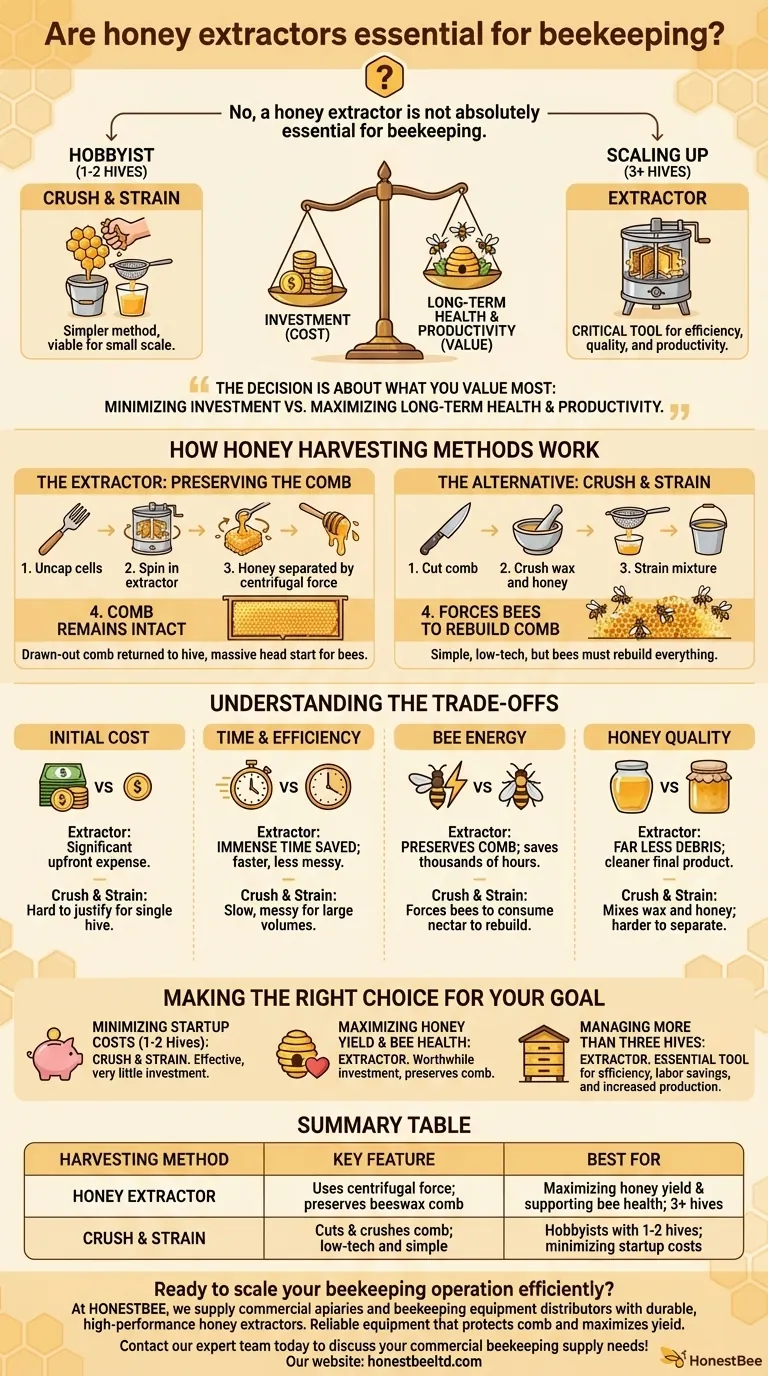

No, a honey extractor is not absolutely essential for beekeeping. For a hobbyist with just one or two hives, the simpler "crush and strain" method is a perfectly viable way to harvest honey. However, an extractor becomes a critical tool for efficiency, honey quality, and hive productivity as soon as you scale up your operation.

The decision to buy a honey extractor is not about whether you can get honey without one; it's about what you value most. It represents a trade-off between minimizing your initial investment and maximizing the long-term health and productivity of your bee colonies.

How Honey Harvesting Methods Work

At its core, honey harvesting is about separating honey from the beeswax comb your bees have built and filled. The method you choose has significant implications for both you and your bees.

The Extractor: Preserving the Comb

A honey extractor is a machine that uses centrifugal force to sling honey out of the comb's cells.

You first uncap the wax-sealed cells with a knife or fork. You then place the frames inside the extractor's basket and spin it, pulling the honey out without destroying the intricate beeswax structure.

The primary benefit is that the comb remains intact. This drawn-out comb can be returned to the hive, giving the bees a massive head start on the next honey flow.

The Alternative: Crush and Strain

The crush and strain method is exactly what it sounds like. It is the traditional, low-tech approach to harvesting.

You simply cut the honeycomb out of the frame and crush it, breaking up all the wax cells. The resulting mixture of honey and wax is then poured through a strainer or filter to separate the two.

This method is simple and requires minimal specialized equipment beyond a bucket and a strainer, but it forces the bees to start from scratch rebuilding all that comb.

Understanding the Trade-offs

Choosing between these two methods involves balancing cost, effort, and the impact on your hives. An extractor is an investment, while crushing and straining has a hidden cost paid by your bees.

Initial Cost vs. Long-Term Efficiency

An extractor is a significant upfront expense. For a beekeeper with a single hive, this cost can be hard to justify.

However, for anyone with three or more hives, the time saved during processing is immense. Extracting is far faster and less messy than crushing and straining large volumes of honey, making it a sound economic choice over time.

Bee Energy vs. Beekeeper Simplicity

Building beeswax is one of the most energy-intensive tasks for a honeybee. It requires them to consume large amounts of nectar that could have otherwise become honey.

By preserving the comb, you are saving your bees thousands of hours of labor. They can immediately begin refilling the empty cells, leading to a much larger honey harvest over the season. The crush and strain method forces them to rebuild every single time.

Honey Quality and Clarity

Both methods require straining to remove impurities like wax particles and debris.

However, extracted honey typically contains far less debris to begin with, resulting in a cleaner final product with less filtering. The crush and strain method thoroughly mixes wax and honey, which can be more difficult to separate completely.

Making the Right Choice for Your Goal

Ultimately, the right equipment depends on the scale of your operation and your primary beekeeping goals.

- If your primary focus is minimizing startup costs with 1-2 hives: Start with the crush and strain method; it's effective and requires very little investment.

- If your primary focus is maximizing honey yield and supporting bee health: An extractor is a worthwhile investment, even for a few hives, because it preserves the bees' most valuable resource: their comb.

- If you are managing more than three hives: The efficiency gains in time, labor, and increased honey production make an extractor an essential tool for serious beekeeping.

Choosing your harvesting method is a key decision that defines your workflow and your relationship with your bees.

Summary Table:

| Harvesting Method | Key Feature | Best For |

|---|---|---|

| Honey Extractor | Uses centrifugal force; preserves beeswax comb | Maximizing honey yield & supporting bee health; 3+ hives |

| Crush & Strain | Cuts & crushes comb; low-tech and simple | Hobbyists with 1-2 hives; minimizing startup costs |

Ready to scale your beekeeping operation efficiently?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, high-performance honey extractors and supplies needed for productive, large-scale harvesting. Our wholesale-focused operations ensure you get the reliable equipment that protects your bees' comb and maximizes your honey yield.

Contact our expert team today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What is the step-by-step guide for honey extraction with a centrifuge? Maximize Efficiency with Ease

- How does increasing the frequency of honey extraction contribute to higher honey yields? Boost Your Apiary Productivity

- Why is an industrial centrifuge essential for pollen extraction from honey? Master Honey Purity and Analysis

- Can a centrifugal honey extractor be used with a top bar hive? Why the Crush and Strain Method is Your Best Bet

- What are the essential hygiene practices to follow when extracting honey? Ensure Purity with Food-Grade Standards