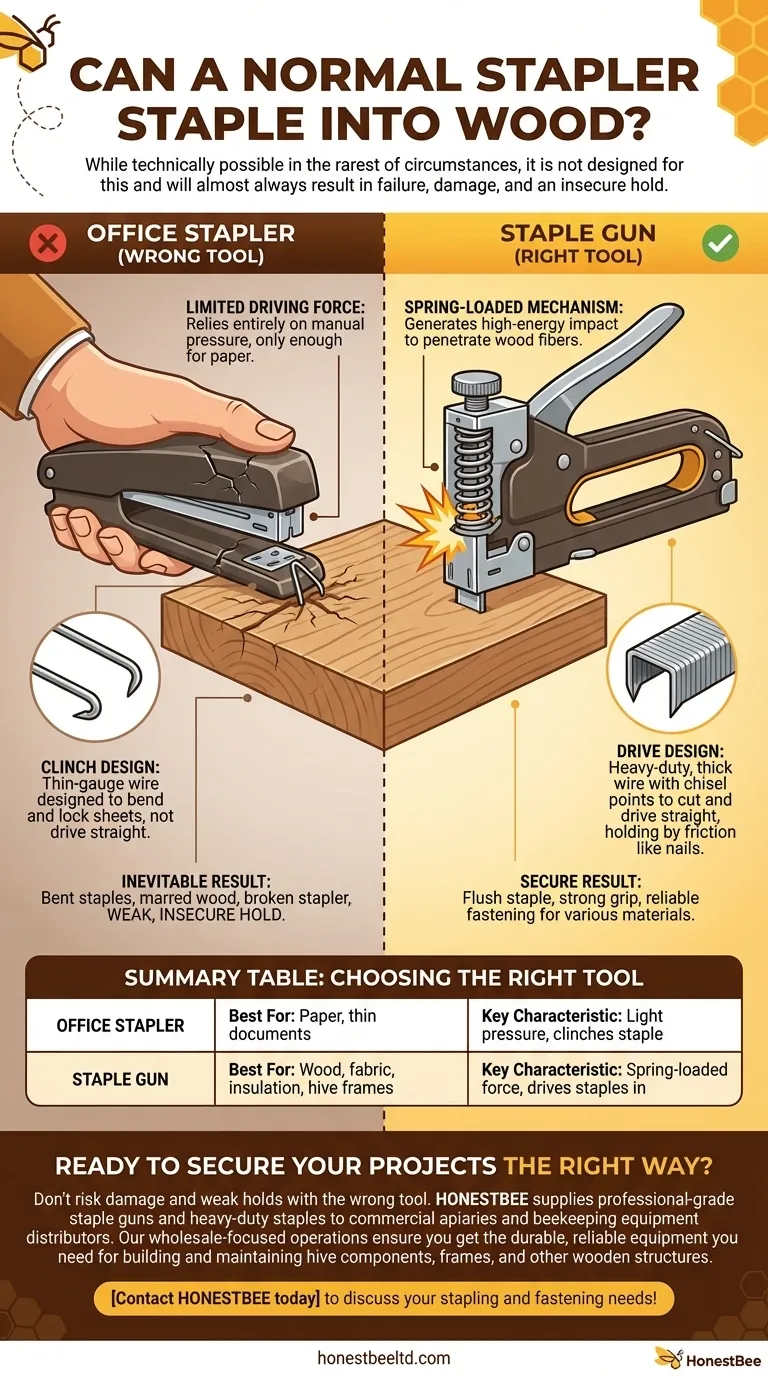

While technically possible in the rarest of circumstances, a normal office stapler is not designed to staple into wood and should not be used for this purpose. The tool lacks the necessary driving force and uses the wrong type of staple, which will almost always result in bent staples, an insecure hold, and potential damage to both the stapler and the wood surface.

The core issue is a mismatch of engineering. An office stapler is designed to pierce paper and clinch a thin staple on the other side. A staple gun is designed to use force to drive a thick, chisel-pointed staple into a solid material where it holds by friction, like a small nail.

Why Your Office Stapler Fails with Wood

An office stapler and a staple gun may seem similar, but they operate on entirely different mechanical principles. Understanding these differences clarifies why one is ineffective where the other excels.

The Problem of Driving Force

A standard office stapler relies entirely on the direct pressure you apply with your hand. This generates a very small amount of force, sufficient only for piercing a few sheets of paper.

In contrast, a manual staple gun uses a powerful spring-loaded mechanism. When you squeeze the handle, you are compressing this spring. At the trigger point, the spring releases, driving the plunger and staple with a sudden, high-energy impact that is essential for penetrating wood fibers.

Staple Design: Clinch vs. Drive

The staples themselves are fundamentally different. Office staples are made from thin-gauge wire. Their primary job is to bend, or clinch, after passing through the paper, locking the sheets together.

Staple gun staples are heavy-duty fasteners. They are made from much thicker wire and have sharp chisel points designed to cut and drive straight into wood without bending. They function like two small nails connected at the top, holding fast through friction.

The Inevitable Result: Failure and Damage

When you attempt to force an office stapler into wood, the thin staple legs will almost always buckle on impact with the dense wood grain. This can mar the wood's surface, and the repetitive force can easily crack the plastic housing or damage the internal mechanism of your stapler.

Understanding the Right Tool: The Staple Gun

To properly fasten materials to wood, a staple gun is the appropriate tool. It is purpose-built for the task, ensuring a secure and durable result.

A Purpose-Built Mechanism

Staple guns are engineered specifically for high-impact driving. Whether manual, electric, or pneumatic (air-powered), their sole purpose is to generate the force needed to sink a fastener into a solid substrate like wood, plywood, or drywall.

Heavy-Duty Staples for a Secure Hold

Staple guns use a wide variety of staples defined by crown width, leg length, and wire gauge. Longer legs provide a deeper, stronger hold in the wood, making them suitable for tasks like upholstery, securing screening, or fastening low-voltage electrical wires.

Understanding the Trade-offs of Using the Wrong Tool

Even if you manage to get an office staple to penetrate a very soft material, the compromise is significant.

The Exception: Extremely Soft Materials

You might successfully drive an office staple into very soft balsa wood or a corkboard. However, this is the absolute limit of the tool's capability and is not a reliable application.

An Insecure Fastening

Even if the staple goes in, the hold will be exceptionally weak. The thin, smooth wire provides minimal friction to grip the wood fibers and can be pulled out with very little effort. This makes it unsuitable for anything that needs to be held securely.

Safety and Quality Concerns

A bent staple that fails to penetrate the wood creates a sharp, protruding hazard. Furthermore, the attempt will likely dent and damage your work surface, leaving an unprofessional finish.

Making the Right Choice for Your Goal

Always match the tool and fastener to the material and the desired outcome.

- If your primary focus is temporarily attaching paper to a soft surface like a bulletin board: A thumbtack or push pin is a much better and safer choice.

- If your primary focus is securely fastening fabric, screen, thin wood trim, or wiring to a wood frame: You must use a staple gun with the correct size of heavy-duty staples.

- If your only tool is an office stapler: Do not attempt to use it on wood. The high probability of failure and damage makes it an unsuitable substitute.

Using the correct tool for the job is the foundation of safe and effective work.

Summary Table:

| Tool | Best For | Key Characteristic |

|---|---|---|

| Office Stapler | Paper, thin documents | Light pressure, clinches staple |

| Staple Gun | Wood, fabric, insulation | Spring-loaded force, drives staples in |

Ready to secure your projects the right way?

Don't risk damage and weak holds with the wrong tool. HONESTBEE supplies professional-grade staple guns and heavy-duty staples to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the durable, reliable equipment you need for building and maintaining hive components, frames, and other wooden structures.

Contact HONESTBEE today to discuss your stapling and fastening needs!

Visual Guide

Related Products

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- HONESTBEE Heavy Duty All Metal Frame Wire Crimper Tool

- Plastic Honey Gate Spout with Wing Nut for Beekeeping Honey Bucket

- Heavy Duty Stainless Steel Queen Bee Catcher Clip

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

People Also Ask

- What are the technical advantages of using professional-grade beehive manufacturing machinery? Scaling Your Apiary

- What are the power requirements and control system for the Bee Box machine? Optimize Your Apiary Equipment Production

- What are the advantages of using industrial hive-making machinery? Scale Your Apiary with Precision

- Why is a multi-material composite structure recommended for modern beehive construction? Master Thermal Efficiency

- How do industrial-grade hive-making machines facilitate large-scale commercial beekeeping? Scale Your Apiary Efficiency

- What is the function of the 5V heating pad in the IBSMC automated beehive? Boost Winter Survival Rates

- Why is precision hive-making machinery indispensable for modern apiaries? The Key to Commercial Scalability

- How does precision hive machinery improve colony survival? Precision Tech for Superior Apiary Results