Yes, you can use a pressure washer to clean a honey extractor, but it requires care. A small pressure washer using only water is effective for removing honey and wax residue from the main drum. However, you must be careful to avoid aiming the high-pressure stream directly at bearings, seals, or other mechanical parts to prevent damage.

While a pressure washer offers a quick way to wash the extractor's interior, the safest and most thorough cleaning process involves scraping solids first, using water to dissolve the honey, and ensuring all components are completely dry before storage.

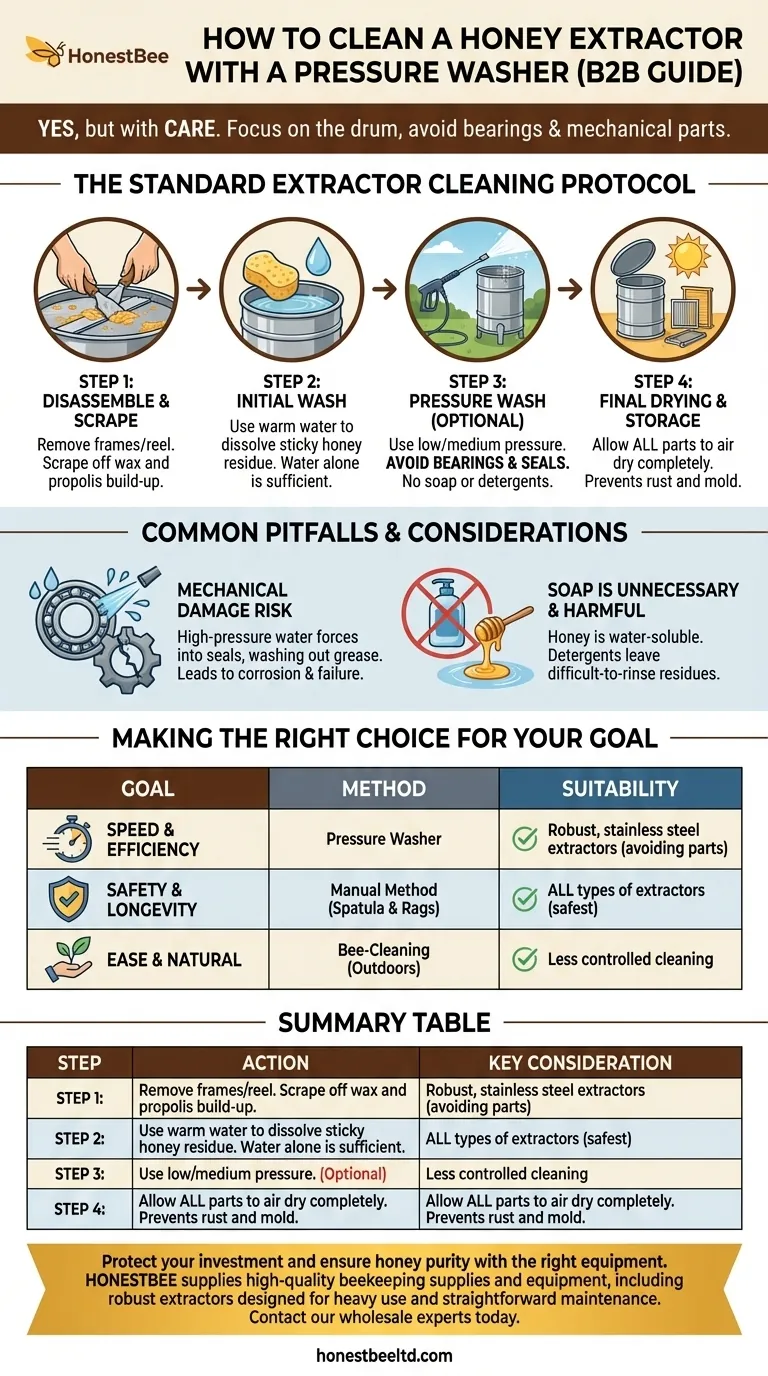

The Standard Extractor Cleaning Protocol

Properly cleaning your extractor isn't just about washing; it's a multi-step process that ensures the longevity of your equipment and the purity of your next harvest.

Step 1: Disassemble and Scrape

Before introducing any water, remove the frames or reel from the extractor drum.

Use a hive tool or a dedicated uncapping knife to scrape off any significant build-ups of wax and propolis from the interior walls and the frames. This makes the washing stage much more efficient.

Step 2: The Initial Wash

This is where you decide on your primary washing tool. The goal is to dissolve and remove all the sticky honey residue.

The most common method is simply using warm water, a soft cloth, or a sponge. You can add water to the drum and spin the reel to clean hard-to-reach areas.

Step 3: Using a Pressure Washer (Optional)

If you choose to use a pressure washer, place the extractor drum and reel on a clean surface outdoors where it can drain.

Use a low-to-medium pressure setting. Stand back to reduce the force of the water striking the surface.

Focus the spray on the stainless steel interior walls and the reel, systematically working from top to bottom. Do not use any soap or detergents, as water alone is sufficient to dissolve honey.

Step 4: Final Drying and Storage

Whether you wash manually or with pressure, this final step is critical.

Allow the extractor drum, reel, and all other parts to air dry completely. This prevents rust on any non-stainless parts and inhibits mold growth.

Once dry, reassemble the unit and cover it to keep it clean for its next use.

Common Pitfalls and Considerations

Using a pressure washer is a powerful technique, but it introduces risks that are not present with manual washing. Understanding these trade-offs is key.

The Risk of Mechanical Damage

The primary danger of a pressure washer is forcing water into places it shouldn't be.

High-pressure water can penetrate the seals of bearings or gearboxes, washing out essential grease. This can lead to corrosion and premature mechanical failure.

Soap is Unnecessary and Harmful

Honey is water-soluble. Warm water and a little manual effort are all that is needed to remove it.

Detergents can leave behind chemical residues that are difficult to rinse completely and can contaminate your next honey harvest.

Exterior Cleaning is Simpler

The outside of your extractor rarely needs more than a quick wipe-down.

Use a damp cloth with cold water to remove any dust or honey that may have dripped or sprayed onto the exterior.

Making the Right Choice for Your Goal

Your cleaning method should match your equipment and your tolerance for risk.

- If your primary focus is speed and efficiency: A pressure washer is a good option for a robust, all-stainless steel extractor, provided you carefully avoid all bearings and mechanical parts.

- If your primary focus is safety and equipment longevity: The manual method using warm water, a spatula, and rags is the safest and most thorough approach for any type of extractor.

- If your primary focus is ease and a natural approach: Allowing your bees to clean the extractor by leaving it outdoors is an option, though it provides a less controlled and complete cleaning.

Choosing the right cleaning method protects your investment and ensures the quality of every future harvest.

Summary Table:

| Step | Action | Key Consideration |

|---|---|---|

| 1. Disassemble & Scrape | Remove frames/reel; scrape off wax/propolis. | Makes washing more efficient. |

| 2. Initial Wash | Use warm water and a cloth/sponge to dissolve honey. | Water alone is sufficient; avoid soap. |

| 3. Pressure Wash (Optional) | Use low-medium pressure on interior walls/reel outdoors. | Crucial: Avoid spraying bearings, seals, and mechanical parts. |

| 4. Dry & Store | Allow all parts to air dry completely before reassembly. | Prevents rust and mold growth. |

Protect your investment and ensure honey purity with the right equipment. For commercial apiaries and distributors, a durable, easy-to-clean honey extractor is essential for operational efficiency. HONESTBEE supplies high-quality beekeeping supplies and equipment, including robust extractors designed for heavy use and straightforward maintenance. Contact our wholesale experts today to discuss your equipment needs and keep your honey harvests running smoothly.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

People Also Ask

- Can manual honey extractors effectively remove honey from cells? A Guide for Small-Scale Beekeepers

- How often should a honey extractor be cleaned? Best Practices for Equipment Longevity

- How do manual and electric honey extractors compare? Choose the Right Tool for Your Harvest Efficiency

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency

- Why is a Centrifugal Honey Extractor essential for maintaining honey quality? Preserve Purity & Boost Apiary Efficiency

- What is the technical significance of using a honey extractor for yield measurement? Isolate Foraging Potential

- What is the primary function of industrial centrifugal honey extractors? Boost Production Efficiency & Preserve Combs

- What are the key considerations for the extraction location? Secure Your Honey Harvest with the Perfect Setup