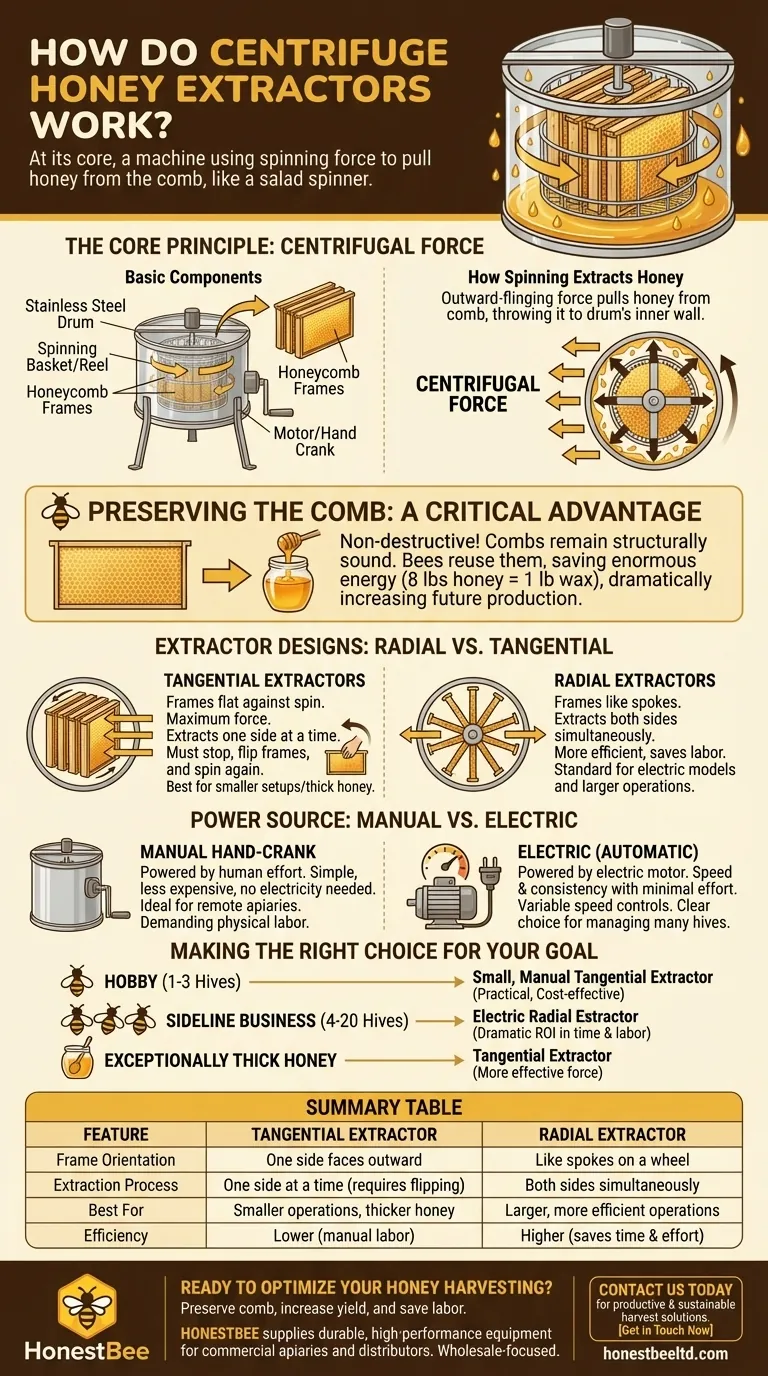

At its core, a centrifuge honey extractor is a machine that uses spinning force to pull honey from the comb. It operates on the same principle as a salad spinner flinging water from lettuce. Honeycomb frames are placed inside a drum, which then spins rapidly, creating a centrifugal force that slings the liquid honey out against the drum's inner wall, leaving the wax comb intact for the bees to reuse.

The critical insight is not just that centrifuges extract honey, but that they do so non-destructively. This preserves the bees' intricate wax comb, saving them enormous energy and dramatically increasing the hive's potential for honey production in the next season.

The Core Principle: Centrifugal Force

A honey extractor is a simple yet highly effective application of physics designed to work with the structure of a honeycomb.

The Basic Components

Every extractor consists of a large drum, typically stainless steel, which contains a basket or reel. The beekeeper places the honey-filled frames into slots in this basket. A mechanism, either a hand crank or an electric motor, spins this basket at high speed.

How Spinning Extracts Honey

As the basket spins, it generates a powerful centrifugal force. This is an outward-flinging force that pulls on any object not at the center of rotation. This force overcomes the honey's viscosity and its adhesion to the wax cells, throwing it from the comb onto the interior wall of the drum.

The Importance of Preserving the Comb

Gravity then pulls the collected honey down to the bottom of the drum, where it can be drained through a tap or honey gate. The now-empty comb remains structurally sound. This is a massive advantage, as bees must consume roughly eight pounds of honey to produce just one pound of wax. Reusing the comb allows the colony to immediately begin refilling it rather than spending weeks rebuilding it from scratch.

Extractor Designs: Radial vs. Tangential

While the principle is the same, the orientation of the frames inside the drum defines the two primary extractor designs.

Tangential Extractors

In a tangential extractor, the frames are positioned so that one side of the comb faces outward, flat against the direction of the spin. This design applies the maximum force to the comb.

However, it only extracts honey from one side at a time. The beekeeper must stop the machine, flip each frame, and spin again to empty the other side. These are common in smaller, manual setups.

Radial Extractors

In a radial extractor, the frames are loaded like spokes on a wheel, with the top bar of the frame facing outward. The centrifugal force pulls honey from both sides of the comb simultaneously.

This design is far more efficient and is the standard for most electric models and larger operations. It saves the significant labor of flipping each frame midway through the process.

Understanding the Trade-offs: Manual vs. Electric

The power source is the most significant differentiator in cost and efficiency.

Manual Hand-Crank Extractors

These are powered by human effort via a hand crank. They are simpler mechanically, less expensive, and do not require electricity, making them ideal for use in remote apiaries. Their primary drawback is the physical labor required, which can be demanding for large harvests.

Electric (Automatic) Extractors

Powered by an electric motor, these extractors offer speed and consistency with minimal effort. They often have variable speed controls, allowing the beekeeper to start slowly to avoid damaging delicate new comb and then ramp up the speed. They are the clear choice for anyone managing more than a few hives.

Making the Right Choice for Your Goal

Selecting an extractor depends entirely on the scale of your beekeeping operation and your goals.

- If your primary focus is a hobby with 1-3 hives: A small, manual tangential extractor is the most practical and cost-effective solution.

- If you are managing a growing sideline business (4-20 hives): An electric radial extractor will provide a dramatic return on investment in time and labor saved.

- If you are processing exceptionally thick honey: A tangential extractor can sometimes be more effective, as it applies force more directly to the face of the comb.

Understanding how these machines work empowers you to select the right tool to efficiently and respectfully harvest the product of your bees' hard work.

Summary Table:

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Frame Orientation | One side faces outward | Like spokes on a wheel |

| Extraction Process | One side at a time, frames must be flipped | Both sides simultaneously |

| Best For | Smaller operations, thicker honey | Larger, more efficient operations |

| Efficiency | Lower (requires manual labor) | Higher (saves time and effort) |

Ready to Optimize Your Honey Harvesting?

As a beekeeper, you know that preserving the bees' wax comb is crucial for hive health and productivity. The right extractor saves your bees weeks of labor and dramatically increases next season's yield.

At HONESTBEE, we supply durable, high-performance honey extractors and beekeeping equipment designed for the demands of commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools you need to scale your operation efficiently.

Contact us today to discuss your needs and discover how our equipment can help you achieve a more productive and sustainable harvest.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

People Also Ask

- How does a centrifugal honey extractor improve product quality and efficiency? Maximize Yield with Clean Separation

- What is the purpose of an electric honey extractor? Scale Your Harvest with Ease

- How does temperature influence the honey extraction process? Master Your Harvest with Thermal Control

- How does a centrifugal honey extractor achieve efficient harvesting? Maximize Yield and Preserve Your Honeycombs

- Why are both ball bearings and bush bearings used in the honey extractor main shaft? Balance Performance & Food Safety

- How long does honey take to extract? A Guide to Streamlining Your Harvest Process

- What are the best practices for storing a honey extractor? Protect Your Investment and Ensure Harvest Hygiene

- How do the Crush & Strain, Centrifugal, and Flow Hive honey extraction methods compare? Find Your Perfect Setup