In short, a fully automatic wax foundation machine saves beekeepers time by producing foundation sheets at a rate that is impossible to match with manual methods. This high-speed automation allows beekeepers to redirect their labor from a repetitive, time-consuming task to more critical aspects of apiary management.

The true value of an automatic machine is not just producing foundation faster; it's about fundamentally changing a beekeeper's workflow. It transforms a major time sink into a streamlined, background process, enabling operational growth and a greater focus on colony health.

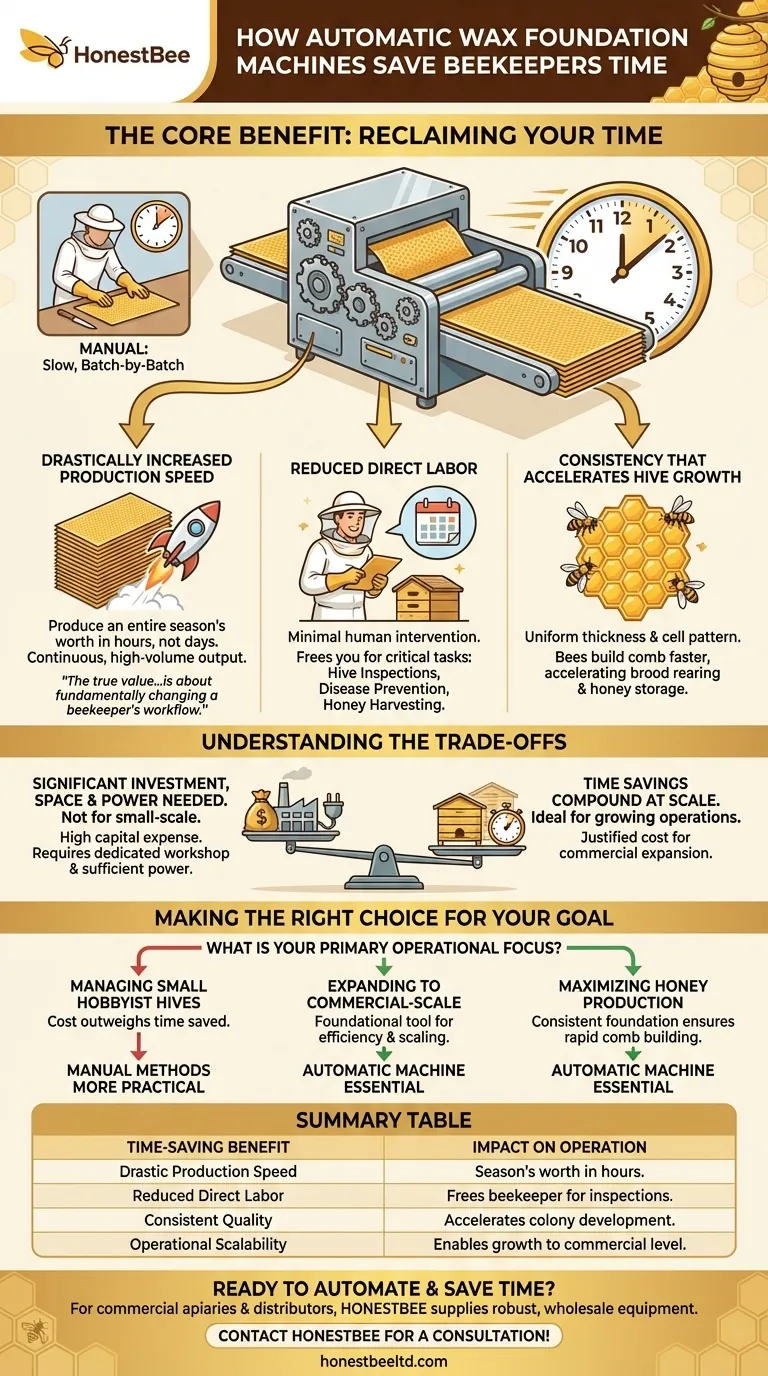

The Core Benefit: Reclaiming Your Time

A beekeeper's time is their most valuable asset. Any task that can be optimized or automated frees up precious hours for hive inspections, disease prevention, and honey harvesting. Automating foundation production is one of the most significant time-saving investments a growing operation can make.

Drastically Increased Production Speed

Manual foundation-making is a slow, batch-by-batch process. A fully automatic machine operates continuously, producing a high volume of sheets with minimal oversight.

This allows you to generate the foundation needed for an entire season in a fraction of the time it would take to do so by hand.

Reduced Direct Labor

Once set up, these machines require very little human intervention to run. This frees the beekeeper from being physically tied to the task.

Instead of spending hours or days making foundation, you can perform other essential apiary work while the machine handles production.

Consistency That Accelerates Hive Growth

Machine production ensures every foundation sheet is of uniform thickness and cell pattern quality.

Bees are more likely to quickly and uniformly draw out high-quality foundation. This consistency accelerates comb building, brood laying, and honey storage, saving time in the hive development cycle.

Understanding the Trade-offs

While the time savings are significant, this technology is not the right fit for every beekeeper. Objectively weighing the costs against the benefits is crucial.

Significant Initial Investment

Fully automatic machines represent a substantial capital expense. The financial outlay is often the biggest barrier to entry for small-scale or hobbyist beekeepers.

Requirement for Space and Power

These are industrial machines that require dedicated workshop space and a sufficient power supply, unlike simple manual presses that can be used almost anywhere.

Not Ideal for Small-Scale Operations

The time-saving benefits truly compound at scale. A beekeeper with only a few hives will likely not save enough time to justify the cost and complexity of an automatic machine.

Making the Right Choice for Your Goal

To determine if this investment aligns with your needs, evaluate your primary operational focus.

- If your primary focus is managing a small number of hobbyist hives: The significant cost is unlikely to be offset by the time saved, making manual methods more practical.

- If your primary focus is expanding into a commercial-scale apiary: This machine is a foundational tool for achieving the production efficiency required to scale your operation and minimize labor costs.

- If your primary focus is maximizing honey production across many hives: The machine's ability to produce consistent, high-quality foundation quickly ensures your colonies can build comb and store nectar without delay.

Automating foundation production allows you to invest your expertise where it matters most: directly with your bees.

Summary Table:

| Time-Saving Benefit | Impact on Beekeeping Operation |

|---|---|

| Drastic Production Speed | Produce a season's worth of foundation in hours, not days. |

| Reduced Direct Labor | Frees the beekeeper for hive inspections and honey harvesting. |

| Consistent Quality | Uniform sheets accelerate comb building and colony development. |

| Operational Scalability | Enables growth from a hobbyist setup to a commercial apiary. |

Ready to Automate Your Foundation Production and Save Valuable Time?

For commercial apiaries and beekeeping equipment distributors, automating your wax foundation production is a strategic investment in efficiency and growth. HONESTBEE supplies the robust, wholesale-focused beekeeping equipment you need to scale your operations and maximize productivity.

Let's discuss how our solutions can help you reclaim your time and focus on what you do best—managing healthy, productive colonies.

Contact HONESTBEE today for a consultation!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets