At their core, honey heating tanks support scalability by providing the operational capacity and process control necessary to handle increasing volumes of honey. As a beekeeping operation grows from a hobbyist level to a commercial enterprise, these tanks allow for efficient processing, consistent product quality, and the flexibility to diversify product offerings without creating production bottlenecks.

The key to understanding their value is seeing a honey heating tank not just as a container, but as a central control system for your entire production workflow. It's the tool that decouples your processing capacity from your hive count, enabling sustainable growth.

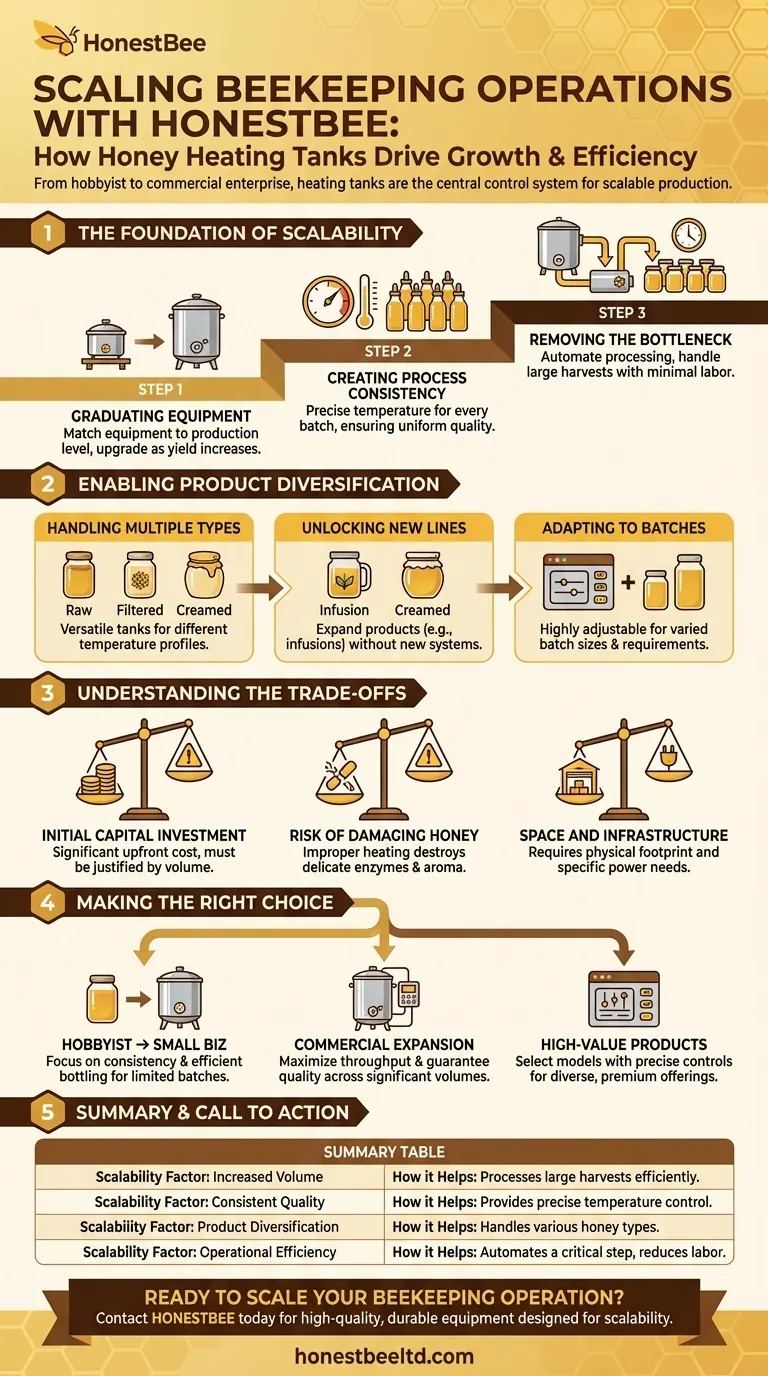

The Foundation of Scalability: Matching Capacity to Production

As your operation grows, every step of the process comes under strain. A heating tank directly addresses the critical bottleneck of preparing honey for bottling or further processing.

Graduating Your Equipment

Honey heating tanks are available in a wide range of sizes, from small tabletop units for hobbyists to massive, industrial-scale vats. This allows you to invest in equipment that matches your current production level and upgrade as your yield increases.

Creating Process Consistency

Scaling a business requires a repeatable, consistent process. A dedicated heating tank ensures that every batch of honey is brought to the precise temperature needed for liquefaction and bottling, maintaining a uniform quality that customers expect.

Removing the Bottleneck

Manually heating and preparing small buckets of honey is manageable at a small scale but becomes a significant bottleneck with larger harvests. A heating tank automates this step, allowing you to process hundreds or thousands of pounds of honey with minimal labor.

Beyond Volume: Enabling Product Diversification

True scalability isn't just about producing more of the same product. It's about having the flexibility to enter new markets and create higher-margin products.

Handling Multiple Honey Types

A key feature of quality heating tanks is their versatility. They are designed to handle everything from raw and filtered honey to delicate creamed honey, each of which may require different temperature profiles.

Unlocking New Product Lines

This versatility allows a growing business to expand its product line without purchasing entirely new systems. The same tank used for liquefying crystallized honey can be used to gently warm honey for infusion or to prepare it for creaming.

Adapting to Batch Variations

More advanced models offer highly adjustable settings. This allows you to perfectly manage different batch sizes and processing requirements, ensuring you don't have to wait for a full tank to begin production.

Understanding the Trade-offs

While essential for growth, investing in a honey heating tank requires careful consideration of its implications.

The Initial Capital Investment

The primary trade-off is the upfront cost. Larger and more sophisticated tanks represent a significant capital investment that must be justified by your production volume and business plan.

The Risk of Damaging Honey

Improper heating is the fastest way to destroy the delicate enzymes and aromas that make honey valuable. A tank without precise, reliable temperature control can do more harm than good, turning a premium product into a generic sweetener.

Space and Infrastructure

Larger tanks require significant physical space and may have specific power requirements. You must plan for the tank's footprint and ensure your facility can support its operation.

Making the Right Choice for Your Goal

Selecting a tank is an investment in your operational future. Your choice should align directly with your specific growth strategy.

- If your primary focus is moving from hobbyist to a small side-business: Choose a smaller, versatile tank that prioritizes consistency and makes the bottling process for limited batches more efficient.

- If your primary focus is expanding an established commercial operation: Invest in a larger-capacity tank with advanced controls to maximize throughput and guarantee quality across significant volumes.

- If your primary focus is creating a diverse, high-value product line: Select a model known for its precise and adjustable temperature controls to expertly handle everything from raw honey to infusions.

Ultimately, the right honey heating tank provides the control and efficiency needed to scale your passion into a thriving business.

Summary Table:

| Scalability Factor | How a Honey Heating Tank Helps |

|---|---|

| Increased Volume | Processes large harvests efficiently, eliminating manual bottlenecks. |

| Consistent Quality | Provides precise temperature control for uniform product quality. |

| Product Diversification | Handles various honey types (raw, creamed, infused) with adjustable settings. |

| Operational Efficiency | Automates a critical step, reducing labor and increasing throughput. |

Ready to scale your beekeeping operation?

For commercial apiaries and equipment distributors, the right honey heating tank is a critical investment in your growth. HONESTBEE supplies high-quality, durable beekeeping equipment designed for scalability and commercial use. Our wholesale-focused operations ensure you get the reliable equipment you need to increase your processing capacity and maintain premium product quality.

Contact HONESTBEE today to discuss the best heating tank solution for your specific growth goals.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

People Also Ask

- How does the performance of honey heat treatment equipment impact HMF levels? Optimize Precision for Quality Control

- What should be done if stored honey crystallizes? Best Techniques for Restoring Texture Without Losing Quality

- What is the primary function of an Industrial Constant Temperature Incubator? Erasing Honey Crystallization Memory

- Why is constant temperature storage equipment essential for raw honey? Preserve Aroma, Color, and Enzyme Activity

- What types of equipment are used for heating honey? Best Methods for Professional Liquefaction and Quality Control

- How does a honey heating tank improve the fluidity of honey? Boost Efficiency with Precision Thermal Control

- What factors should be considered when choosing a honey bucket heater? Protect Honey Quality with Precise Heat

- What is the purpose of heating honey during processing? Optimize Flow, Filtration, and Shelf Stability Efficiently