For beekeepers, the choice between wooden and plastic frames directly impacts the efficiency of honey extraction. During this high-force process, wooden frames demonstrate superior structural integrity and are far less likely to warp or bend compared to their plastic counterparts. This rigidity ensures they can be reliably reused batch after batch without issue.

The core issue isn't just about wood versus plastic, but about structural resilience. Wooden frames, especially when properly wired, maintain their shape under the centrifugal force of an extractor, while plastic frames carry a significant risk of warping, which complicates future use.

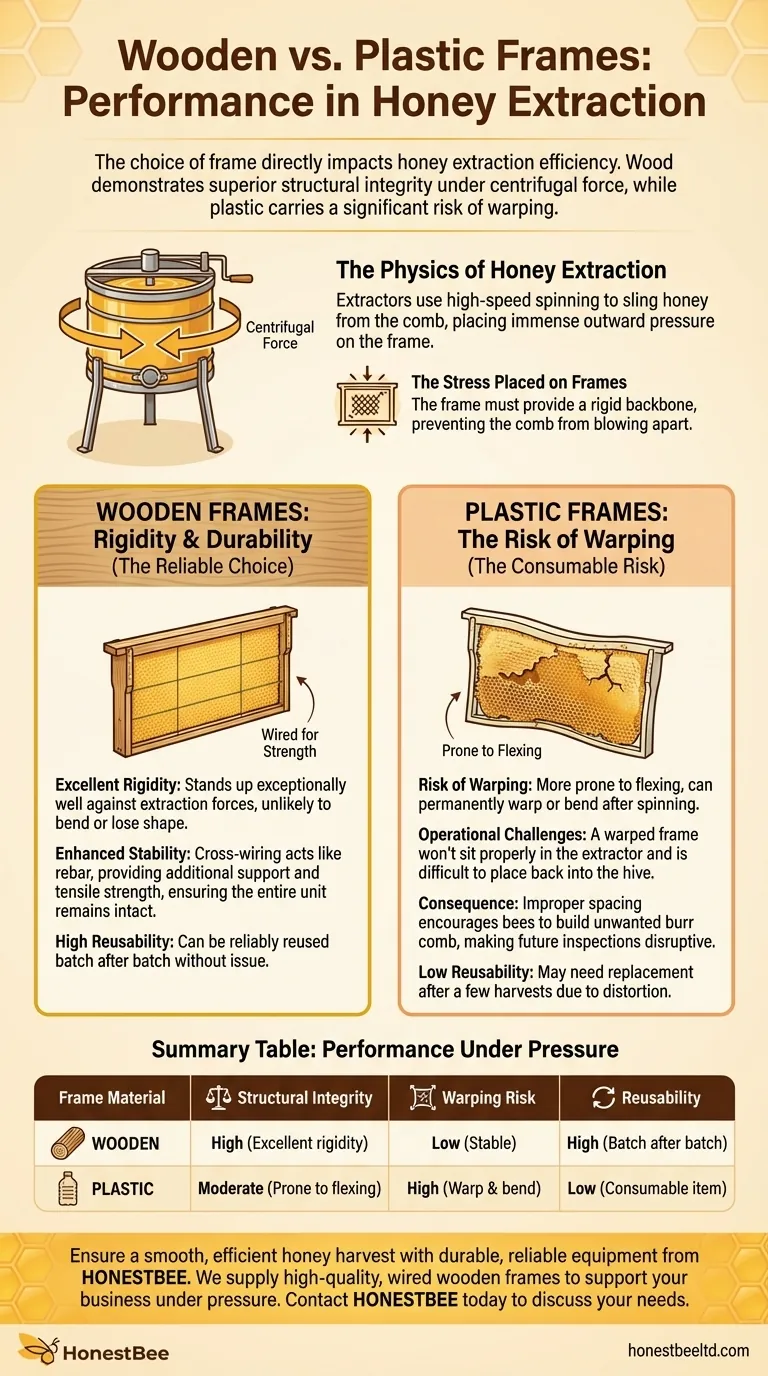

The Physics of Honey Extraction

To understand frame performance, you must first appreciate the forces at play. Honey extraction is a physically demanding process for your equipment.

How a Honey Extractor Works

A honey extractor uses centrifugal force to sling honey out of the comb. Frames are placed inside a drum-like container which then spins at high speed, generating immense outward pressure on the frame and the wax comb it holds.

The Stress Placed on Frames

This spinning force pulls the heavy, honey-filled comb away from the frame's foundation. The frame's job is to hold its shape and provide a rigid backbone, preventing the delicate wax comb from blowing apart under the strain.

Frame Performance Under Pressure

The material of your frame determines how it responds to the stress of extraction. This is where the difference between wood and plastic becomes most apparent.

Wooden Frames: Rigidity and Durability

Wooden frames are known for their rigidity. They stand up exceptionally well against the forces inside an extractor and are very unlikely to bend or lose their shape.

This structural stability is often enhanced with cross-wiring, which provides additional support to the foundation and comb, ensuring the entire unit remains intact even during aggressive spinning.

Plastic Frames: The Risk of Warping

While convenient in other ways, plastic frames can be a liability during extraction. The material is more prone to flexing and can permanently warp or bend after being spun.

A warped frame is difficult to work with. It won't sit properly in the extractor for subsequent batches and, more importantly, can be challenging to place back into the hive.

Understanding the Trade-offs

Choosing a frame is about more than just its performance in the extractor. However, failure at this stage can create problems that ripple through your entire beekeeping operation.

The Consequence of a Warped Frame

A warped plastic frame is not just an inconvenience. When you try to put it back in the hive, the improper spacing can encourage bees to build unwanted burr comb, making future hive inspections difficult and disruptive.

Why Wiring is Critical

The reference to "wired frames" remaining in good shape is key. This practice is most common with wooden frames and is a primary reason for their superior performance. The wires act like rebar in concrete, adding immense tensile strength that prevents distortion.

The Broader Context

This analysis focuses specifically on the extraction process. Plastic frames may offer other advantages, such as resistance to wax moths or perceived ease of cleaning, but these benefits must be weighed against the significant risk of warping during the harvest.

Making the Right Choice for Your Harvest

Your decision should be guided by your tolerance for equipment failure during one of the most labor-intensive parts of the beekeeping season.

- If your primary focus is a reliable and repeatable extraction process: Choose high-quality, wired wooden frames for their proven durability and resistance to warping.

- If you are using plastic frames for other benefits: Be aware of the warping risk and consider them a potentially consumable item that may need replacement after a few harvests.

Ultimately, selecting frames that withstand the rigors of extraction ensures a smoother harvest and promotes a healthier, more manageable hive.

Summary Table:

| Frame Material | Structural Integrity | Warping Risk | Reusability |

|---|---|---|---|

| Wooden | High (Excellent rigidity) | Low | High (Can be reused batch after batch) |

| Plastic | Moderate (Prone to flexing) | High | Low (May warp and need replacement) |

Ensure a smooth, efficient honey harvest with durable, reliable equipment from HONESTBEE. We supply high-quality, wired wooden frames and other essential beekeeping supplies to commercial apiaries and distributors. Our wholesale-focused operations are designed to support your business with equipment that performs under pressure. Contact HONESTBEE today to discuss your needs and discover how we can help you achieve a more productive season.

Visual Guide

Related Products

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Assembled Wooden Bee Frames with Plastic Foundation for Durability and Convenience by HONESTBEE

- Heavy-Duty Stainless Steel Clip-On Frame Perch

- Durable Rubberized Comfort Handle Frame Grip

People Also Ask

- Why is it important to compress frames together in the center of the box after reassembly? Prevent Burr Comb and Hive Chaos

- What is the purpose of pre-treating grafting frames? Boost Acceptance with These Essential Beekeeping Tips

- How to wire a bee frame? A Step-by-Step Guide for Strong, Durable Honeycomb

- What are deep super frames and what do they contain? Essential Guide to Hive Foundations

- What are Flow frames? Revolutionize Your Harvest with Low-Impact Extraction Technology

- How should frames be arranged when adding a honey super? Optimize Spacing for Better Yield and Easier Harvesting

- What are the characteristics of plastic hive frames? Durable, Low-Maintenance Solutions for Modern Apiaries

- Why should holes be added to the sidebars of beehive frames? Enhance Stability with Precision Wiring