At its core, a honey filling machine improves productivity by automating the most repetitive and time-consuming stage of packaging. This automation delivers a dramatic increase in speed over manual methods, ensures every jar is filled with exacting precision, and significantly reduces the need for direct manual labor.

The true value of a honey filling machine isn't just that it fills jars faster; it's that it transforms the entire packaging process into a consistent, hygienic, and scalable operation, minimizing product waste and freeing up human capital for higher-value tasks.

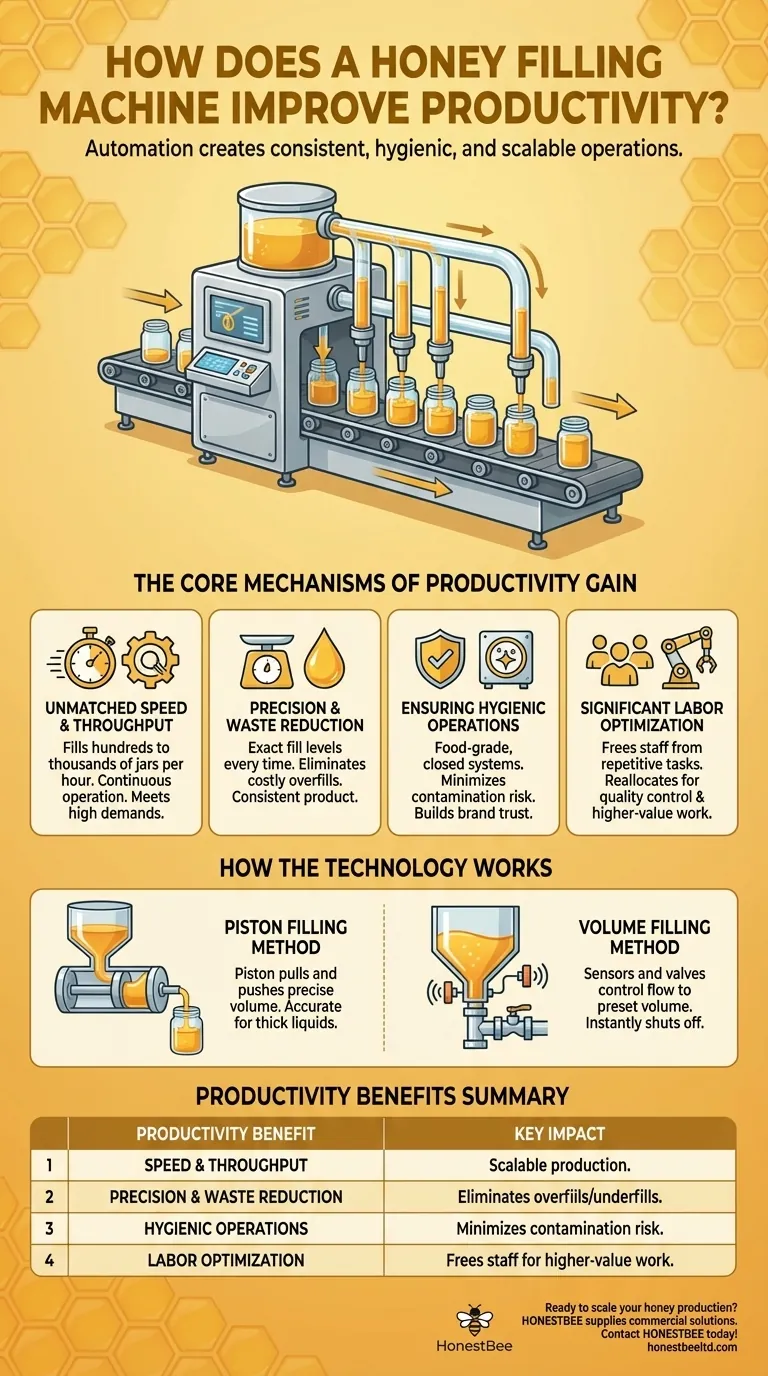

The Core Mechanisms of Productivity Gain

Automating the filling process creates a cascade of efficiencies that go far beyond simply replacing a person with a funnel. Each mechanical function is designed to optimize a specific aspect of production.

Unmatched Speed and Throughput

An automated filler works continuously at a consistent pace, without fatigue or breaks. This allows a business to dramatically increase its output, filling hundreds or thousands of jars per hour compared to the much slower rate of manual filling.

This consistent high speed makes production planning more predictable and allows producers to meet larger orders and market demands effectively.

Precision and Waste Reduction

Manual filling is inherently inconsistent. Some jars get overfilled, giving away free product, while others are underfilled, risking customer dissatisfaction and non-compliance with labeling laws.

Honey filling machines use precise mechanisms, such as pistons or volumetric sensors, to dispense the exact same amount of honey every single time. This eliminates costly overfills and ensures a professional, consistent product.

Ensuring Hygienic Operations

These machines are built with food-grade materials, like stainless steel, and operate as closed systems. This minimizes the honey's exposure to airborne contaminants and human contact during the filling process.

Enhanced hygiene reduces the risk of spoilage or contamination, which prevents costly product recalls and builds brand trust.

Significant Labor Optimization

Automating the filling process frees your team from a tedious and repetitive task. A single operator can often oversee the machine's function, allowing other staff to be reallocated to quality control, labeling, packing, and shipping.

This isn't about eliminating jobs, but rather optimizing your workforce for more complex and valuable activities that a machine cannot perform.

How the Technology Works

Understanding the basic mechanics reveals why these machines are so effective for a viscous product like honey.

The Piston Filling Method

A piston filler is one of the most common types for honey. The machine uses a piston that pulls back to draw a precise volume of honey from a hopper into a cylinder. The piston then pushes forward, dispensing that exact amount into the jar through a nozzle.

The speed and volume are easily adjusted, making this method highly accurate and reliable for thick liquids.

The Volume Filling Method

A volume filler, or volumetric filler, relies on sensors and valves. An operator sets the desired fill volume on a control panel. The machine then allows honey to flow from the hopper through the nozzle until sensors detect that the preset volume has been reached, at which point a valve shuts off the flow instantly.

Understanding the Trade-offs

While highly effective, integrating a filling machine requires careful consideration.

Initial Capital Investment

The most significant factor is the upfront cost of the machinery. For small-scale or hobbyist beekeepers, the investment may not provide an immediate return compared to manual methods.

Maintenance and Cleaning Requirements

To maintain hygienic standards and operational reliability, these machines require disciplined cleaning and regular maintenance. This represents an ongoing commitment of time and resources.

Operational Flexibility

While many machines offer adjustable volume settings, changing between vastly different jar shapes and sizes can require time for recalibration or even different parts. This can be less flexible than manual filling for producers with a wide variety of very small, custom batches.

Making the Right Choice for Your Operation

The decision to invest in a honey filling machine depends entirely on your business goals.

- If your primary focus is scaling production: The machine's sheer speed and continuous operation are the key to meeting higher demand and growing your business.

- If your primary focus is brand consistency and quality: The machine's precision filling and hygienic process ensure every single jar meets your quality standards.

- If your primary focus is long-term cost efficiency: The savings from reduced product waste and optimized labor will provide a clear return on the initial investment over time.

Ultimately, adopting a honey filling machine is the critical step in moving from a manual craft to a professional, scalable food production system.

Summary Table:

| Productivity Benefit | Key Impact |

|---|---|

| Speed & Throughput | Fills hundreds to thousands of jars per hour, enabling scalable production. |

| Precision & Waste Reduction | Ensures exact fill levels every time, eliminating costly overfills and underfills. |

| Hygienic Operations | Uses food-grade, closed systems to minimize contamination risk and build brand trust. |

| Labor Optimization | Frees staff from repetitive tasks for higher-value work like quality control and shipping. |

Ready to scale your honey production with professional-grade efficiency? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, high-performance honey filling machines designed for high-volume operations. Our wholesale-focused solutions help you maximize throughput, minimize waste, and optimize your labor costs. Contact HONESTBEE today to find the perfect filling solution for your business!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the function of industrial honey-filling and packaging machinery? Accelerate Your Commercial Scale-Up

- What are the recommended applications for a honey filling machine? Precision Solutions for Honey and Pharmaceuticals

- What are the functional benefits of using automated honey filling machines? Optimize Your Honey Supply Chain Efficiency

- Which factors determine the operational efficiency of professional honey-filling machines? Boost Your Production Flow

- What technical advantages do automatic honey-filling machines provide? Elevate Your Production Standards

- What is the role of automated honey-filling machines in the post-processing of honey products? Boost Brand & Quality

- Why is the use of high-precision automatic filling and sealing machines critical in propolis aerosol production?

- What is the process of stick pack packaging for honey? A Guide to Efficient Single-Serve Production