At its core, a premade pouch packaging machine automates the process of filling and sealing ready-made bags. The machine uses a series of grippers to pick up an empty pouch, transport it through stations that open it, fill it with a product like honey, and then apply heat and pressure to create a secure final seal.

A premade pouch machine is best understood as a specialized assembly line for your packaging. Its primary value lies in its ability to handle high-quality, pre-printed pouches with precision, ensuring a consistent and professional final product with minimal manual intervention.

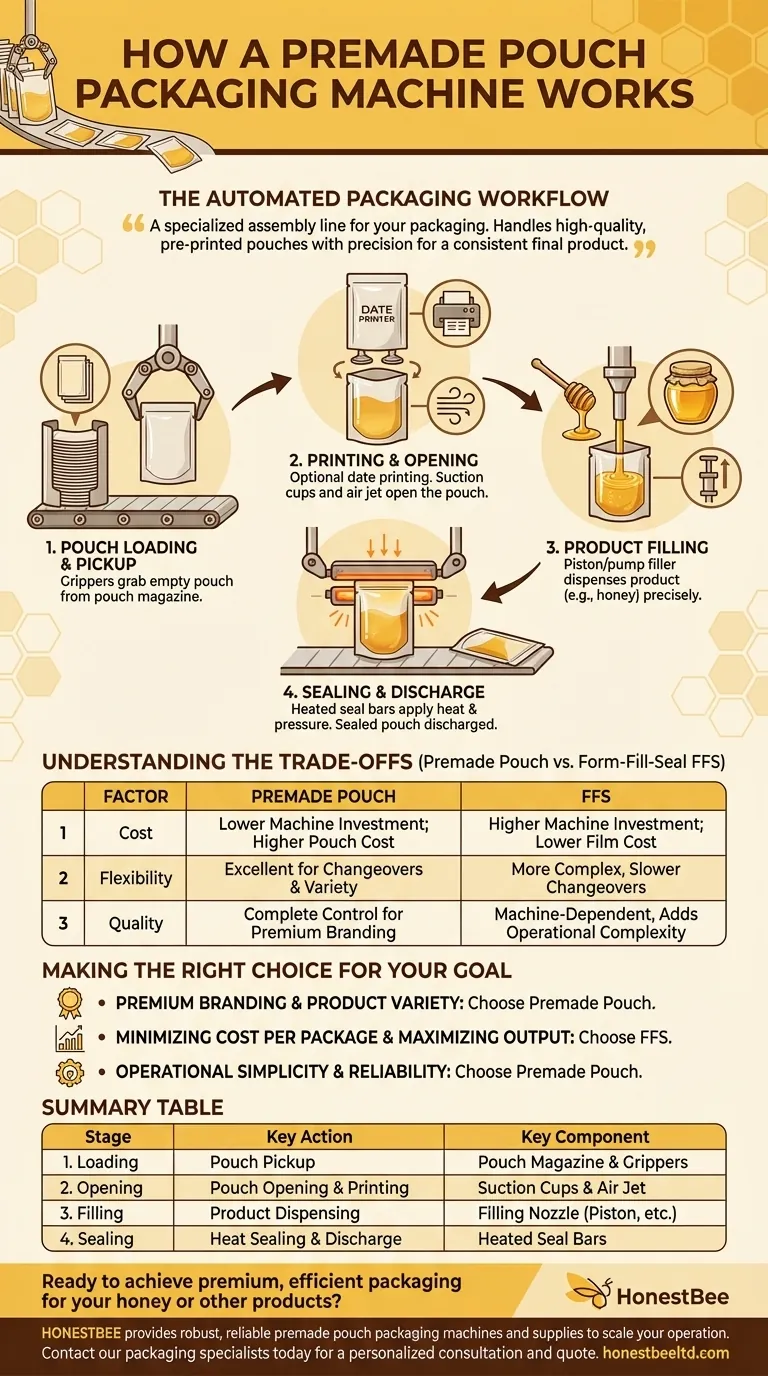

The Automated Packaging Workflow

A premade pouch machine typically operates on a rotary or linear transport system. Think of it as a carousel or a conveyor belt with multiple "stations," where each station performs one specific task in sequence.

Station 1: Pouch Loading and Pickup

The process begins by loading a stack of empty, premade pouches into a pouch magazine.

A set of grippers—the machine's "hands"—grabs a single pouch from the magazine. On rotary machines, these grippers are mounted on arms that will rotate the pouch from one station to the next.

Station 2: Printing and Opening

If required, the pouch passes through an optional date coding or printing station to add expiration dates or lot numbers.

Next, a sensor confirms the pouch is in the correct position. A pair of suction cups or opening jaws then grasps the top of the pouch, pulling it open. To ensure it opens fully, a jet of clean air is often blown into the bag.

Station 3: Product Filling

This is the most critical station. The opened pouch is positioned precisely under a filling nozzle.

The type of filler used depends entirely on the product. For liquids like honey, a piston or pump filler is used for accuracy. For powders, an auger filler is common, and for solids like snacks, a multi-head weigher is used to measure the correct portion.

Station 4: Sealing and Discharge

After filling, the top of the pouch is brought to the sealing station. Here, two heated seal bars clamp down on the top edge of the pouch.

Through a combination of heat, pressure, and time (known as dwell time), the sealant layers of the pouch are fused together to create a strong, airtight seal. The sealed pouch is then discharged from the machine onto a takeaway conveyor for packing into cases.

Understanding the Trade-offs

Choosing a premade pouch machine involves clear trade-offs against other technologies, primarily Form-Fill-Seal (FFS) machines which create pouches from a roll of film.

Pouch Cost vs. Equipment Cost

Premade pouches are more expensive per unit than the raw rollstock film used by FFS machines. However, the initial investment in a premade pouch machine is often lower and the machinery itself is mechanically simpler.

Flexibility vs. Speed

Premade pouch machines offer excellent flexibility. Changing between different pouch sizes or styles is typically faster and requires fewer changeover parts compared to a complex FFS system.

However, top-end FFS machines can often achieve higher output speeds because they are not limited by the mechanical action of picking and placing individual bags.

Quality Control and Presentation

Using premade pouches gives you complete control over the pouch's quality and printing, which is ideal for premium branding. Issues like poor seal quality or bad artwork are resolved by the pouch supplier, not your machine.

With FFS, you are responsible for forming the pouch correctly on the machine, which adds a layer of operational complexity.

Making the Right Choice for Your Goal

Deciding on the right packaging automation depends entirely on your business priorities.

- If your primary focus is premium branding and product variety: A premade pouch machine is the superior choice, as it excels at handling high-quality, pre-printed pouches and allows for faster changeovers between different products (SKUs).

- If your primary focus is minimizing cost-per-package and maximizing output: A Form-Fill-Seal (FFS) machine is likely the more economical solution in the long run, especially for high-volume production of a single product.

- If your primary focus is operational simplicity and reliability: A premade pouch machine is generally simpler to operate and maintain, as it separates the pouch manufacturing process from the filling and sealing process.

Understanding this core distinction empowers you to invest in the technology that directly serves your operational and financial goals.

Summary Table:

| Stage | Key Action | Key Component |

|---|---|---|

| 1. Loading | Pouch Pickup | Pouch Magazine & Grippers |

| 2. Opening | Pouch Opening & Printing | Suction Cups & Air Jet |

| 3. Filling | Product Dispensing | Filling Nozzle (Piston, Auger, etc.) |

| 4. Sealing | Heat Sealing & Discharge | Heated Seal Bars |

Ready to achieve premium, efficient packaging for your honey or other products?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides the robust, reliable premade pouch packaging machines and supplies you need to scale your operation. Our experts can help you select the perfect equipment to enhance your branding, increase output, and simplify your workflow.

Contact our packaging specialists today for a personalized consultation and quote.

Visual Guide

Related Products

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Professional Durable Customizable Blister Packing Machine

- Semi Automatic Electric Bottle Capping Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- What role do industrial honey-filling machines play in processing specialty honeys? Scale Your Brand for Export

- What role do automatic honey-filling machines play in the commercialization of stingless bee honey products?

- What is the primary function of an automated honey-filling machine? Maximize Efficiency & Purity in Your Production Line

- How do automated honey-filling machines and processing equipment help apiaries mitigate risks? Beat Climate-Induced Yields

- What is the advantage of the compact size of the honey filling machine? Maximize Efficiency in Limited Spaces

- What is the process of a sachet filling machine? Optimize Your Packaging Line for Accuracy & Speed

- How do industrial honey-filling and processing machines contribute to regional food security? Stabilizing Supply Chains

- What are the advantages of using automated honey-filling machines? Boost Precision and Scale Your Commercial Apiary