At its core, a bottle cap sealing machine is an automated system designed to apply and secure a closure onto a container like a bottle or jar. These machines range from simple devices that apply a single type of cap to complex systems integrated into a full packaging line. Their primary function is to create a secure, often airtight, seal that protects the product inside.

A bottle cap sealing machine is more than just a device for putting lids on containers; it is a critical control point in manufacturing that guarantees product integrity, safety, and shelf life by creating a secure and often tamper-evident barrier.

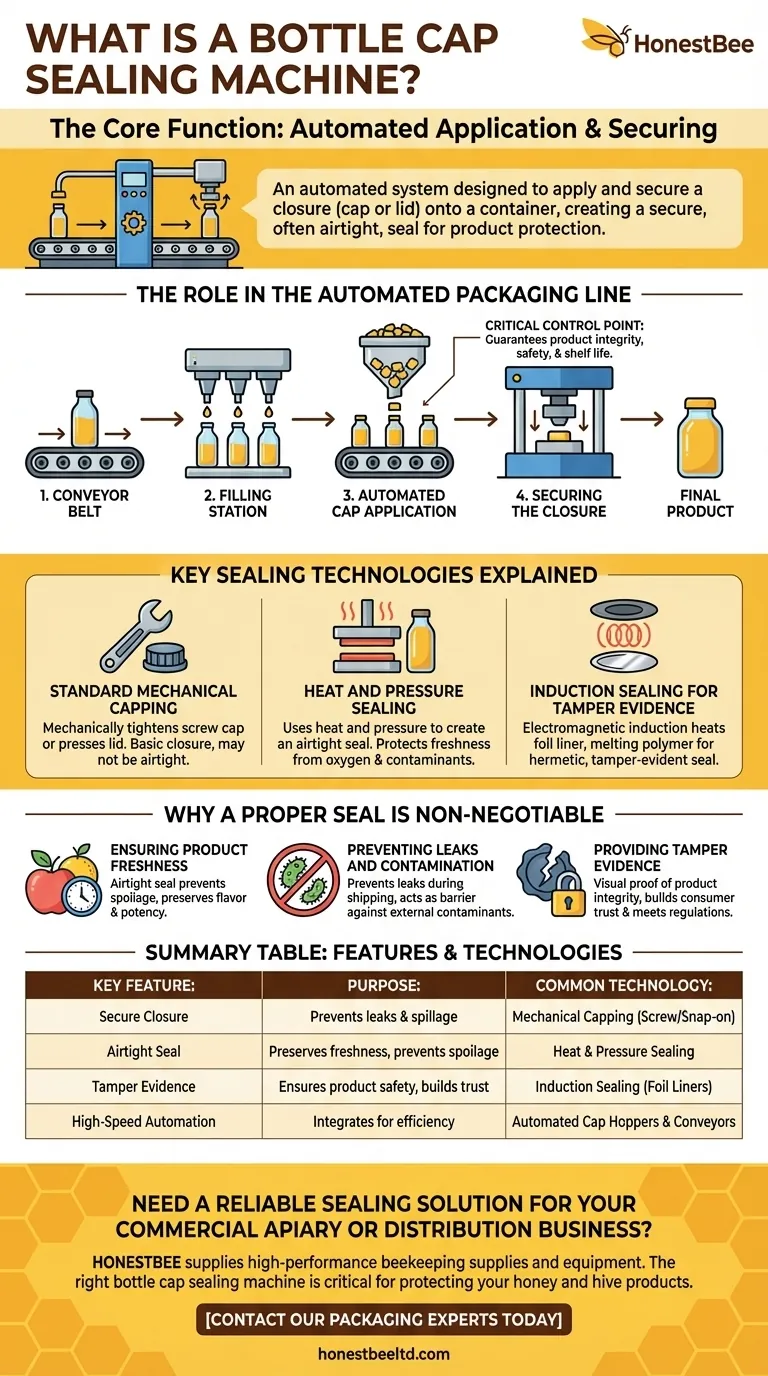

The Role in the Automated Packaging Line

A sealing machine rarely operates in isolation. It is a key stage in a larger, automated process designed for efficiency and consistency.

From Filling to Final Product

The container's journey typically begins on a conveyor belt. First, it passes through a filling station where nozzles dispense a precise amount of product. Immediately after, it moves to the capping and sealing station.

Automated Cap Application

High-volume operations use machines that store thousands of caps in a hopper or tank. These systems automatically orient and place the correct cap onto each container as it passes, preparing it for the final sealing step.

Securing the Closure

Once the cap is placed, the sealing mechanism engages. This can involve tightening a screw cap to a specific torque, pressing on a snap-on lid, or applying a more advanced sealing technology to ensure the container is completely closed.

Key Sealing Technologies Explained

The term "sealing" can refer to different methods, each serving a distinct purpose in product protection. Understanding the technology is key to understanding the machine's value.

Standard Mechanical Capping

This is the most straightforward method, where the machine mechanically tightens a screw-on cap or presses a lid firmly into place. While this closes the container, it may not provide a perfect airtight seal on its own.

Heat and Pressure Sealing

For many applications, a simple mechanical closure isn't enough. Sealing machines often use a combination of heat and pressure to create a truly airtight seal. This protects the contents from oxygen and contaminants, which is vital for product freshness and safety.

Induction Sealing for Tamper Evidence

A highly effective method is induction sealing. This process uses electromagnetic induction to heat a foil liner inside the cap. The heat melts a polymer layer on the foil, which then adheres to the rim of the container, creating a hermetic, tamper-evident seal that provides the highest level of protection against leaks and contamination.

Why a Proper Seal is Non-Negotiable

The quality of the seal has a direct impact on product quality, consumer safety, and brand reputation.

Ensuring Product Freshness

An airtight seal is crucial for preventing spoilage. It keeps oxygen out and preserves the flavor, potency, and quality of the contents, which is essential in the food, beverage, and pharmaceutical industries.

Preventing Leaks and Contamination

A secure closure prevents the product from leaking during shipping and handling. More importantly, it acts as a barrier against external contaminants like bacteria and moisture, ensuring the product remains safe for consumption.

Providing Tamper Evidence

Seals, especially induction foil seals, provide clear visual proof that a product has not been opened or tampered with prior to purchase. This builds consumer trust and is a regulatory requirement for many types of products.

Making the Right Choice for Your Goal

Selecting the right sealing approach depends entirely on your product's requirements and your operational scale.

- If your primary focus is simple containment: A standard mechanical capper that screws or presses on a lid is often sufficient for products that are not sensitive to air.

- If your primary focus is freshness and safety: A machine that uses heat and pressure or, ideally, induction sealing is necessary to create an airtight and tamper-evident closure.

- If your primary focus is high-volume production: Integrating a fully automated capping and sealing machine into a complete line with fillers and labelers is the only way to achieve necessary speed and consistency.

Ultimately, investing in the correct sealing technology is a direct investment in the quality and safety of your final product.

Summary Table:

| Key Feature | Purpose | Common Technology |

|---|---|---|

| Secure Closure | Prevents leaks and spillage | Mechanical Capping (Screw/Snap-on) |

| Airtight Seal | Preserves freshness, prevents spoilage | Heat & Pressure Sealing |

| Tamper Evidence | Ensures product safety, builds consumer trust | Induction Sealing (Foil Liners) |

| High-Speed Automation | Integrates with filling lines for efficiency | Automated Cap Hoppers & Conveyors |

Need a reliable sealing solution for your commercial apiary or distribution business?

HONESTBEE supplies high-performance beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. The right bottle cap sealing machine is critical for protecting your honey and other hive products, ensuring they reach your customers in perfect condition.

Contact our packaging experts today to discuss how we can integrate the right sealing technology into your operation to guarantee product integrity, safety, and efficiency.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Semi Automatic Electric Bottle Capping Machine

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

People Also Ask

- What are the key considerations and methods for sealing honey jars with a lid? Ensure Freshness & Airtight Seals

- How do bee product packaging and sealing equipment influence the cost-benefit analysis? Maximize Your Honey Profits

- How do I choose a mechanical seal? A 4-Pillar Guide for Optimal Performance & Reliability

- What role do specialized beehive sealing and transport equipment play in migratory beekeeping for stingless bees?

- How do modern packaging and sealing machines protect black honey? Unlock Global Quality and Premium Brand Value

- Why is the use of high-performance sealing consumables critical for honey retail packaging? Ensure Purity & Shelf Life

- What is the purpose of induction sealing in honey packaging? Ensure Quality & Build Consumer Trust

- What is the purpose of using modified sealing caps and industrial tape in bridging propagation? Boost Hive Acceptance