At its core, a bottle machine works by moving empty containers along a conveyor system to a filling station, where a precise volume of liquid is dispensed. Once filled, the container continues to subsequent stations for capping, sealing, and labeling, creating a finished product ready for distribution. The entire process is a synchronized sequence of discrete, automated tasks.

A bottling machine isn't a single device but an integrated production line. Its fundamental principle is moving containers through sequential, specialized stations—filling, capping, and labeling—each optimized for precision, consistency, and speed.

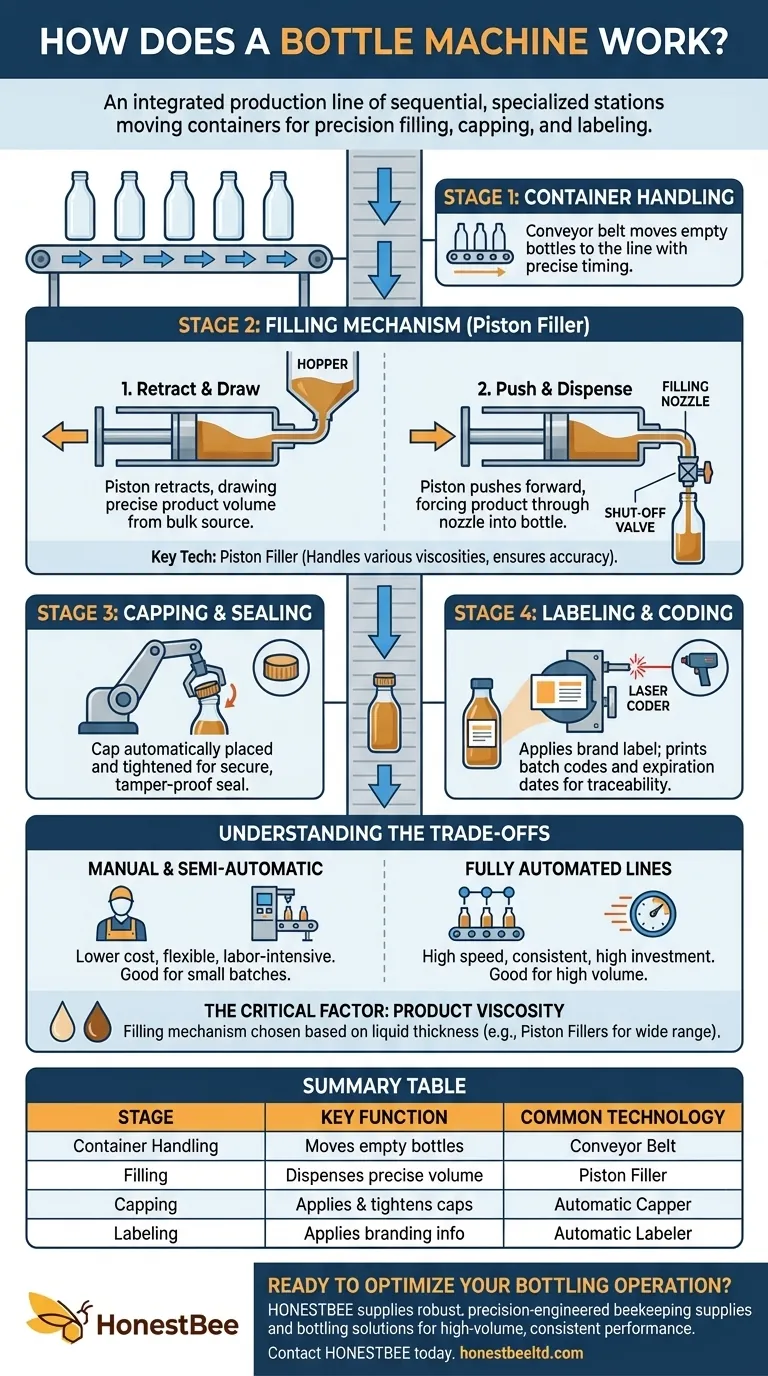

The Core Stages of an Automated Bottling Line

To understand how a bottle machine works, it's best to follow the journey of a single bottle from start to finish. The entire system is built around a central conveyor that ensures a smooth and continuous flow.

Stage 1: Container Handling and Conveyance

The process begins with empty bottles or jars being placed onto a conveyor belt. This belt acts as the transport system, moving containers in an orderly fashion from one station to the next with precise timing.

Stage 2: The Filling Mechanism

This is the heart of the operation. The conveyor stops the container directly under a filling head. While many technologies exist, a common and reliable method is the volumetric piston filler.

How a Piston Filler Works

A piston inside a cylinder retracts, drawing a pre-measured, exact volume of product from a bulk source like a hopper or tank.

As the bottle is positioned, the piston then pushes forward, forcing the product out of the cylinder and into the bottle through a filling nozzle.

To ensure accuracy and prevent dripping, these nozzles use precise shut-off valves that close the instant the predetermined value is dispensed. This mechanism is often powered pneumatically for reliable and repeatable force.

Stage 3: Capping and Sealing

After being filled, the bottle moves to the capping station. Here, a cap is automatically placed and tightened onto the container, securing the product and ensuring it is tamper-proof and leak-proof.

Stage 4: Labeling and Coding

The final automated stage is labeling. The sealed bottle passes through a labeler that applies the product brand, nutritional information, and other essential details. Often, an inkjet or laser coder will also print batch codes and expiration dates onto the bottle or label for traceability.

Understanding the Trade-offs

Not all bottling operations are the same. The choice of machinery depends heavily on production scale, product type, and budget.

Manual and Semi-Automatic Fillers

For smaller operations, a manual bottle filling machine is a common starting point. These devices still use a pneumatically powered pump and piston mechanism for accuracy but require an operator to place the bottle and initiate each fill cycle.

They offer flexibility and a lower initial investment but are limited in speed and are labor-intensive.

Fully Automated Lines

Large-scale producers use fully integrated lines where every stage—from bottle feeding to final case packing—is automated. These systems provide immense speed and consistency but require significant capital investment and dedicated floor space.

The Critical Factor: Product Viscosity

The type of filling mechanism is dictated by the liquid's characteristics. Piston fillers are excellent for a wide range of products, from thin liquids to thicker substances like sauces or creams, because they actively force the product into the container. Other technologies exist for different needs, such as gravity fillers for low-viscosity liquids or overflow fillers for achieving a consistent cosmetic fill level.

Making the Right Choice for Your Goal

Selecting the right bottling technology requires aligning the machine's capabilities with your specific production objectives.

- If your primary focus is small-batch or craft production: A manual or semi-automatic piston filler provides the necessary accuracy and flexibility without the high cost of a full line.

- If your primary focus is high-volume, uniform manufacturing: A fully integrated and automated line is the only way to achieve the required speed, consistency, and low per-unit labor cost.

- If your primary focus is handling various product types: Prioritize a system with quick-change parts and a filling mechanism, like a piston filler, that can handle a wide range of viscosities.

Understanding this workflow from container transport to final labeling is the key to mastering any bottling operation.

Summary Table:

| Stage | Key Function | Common Technology |

|---|---|---|

| Container Handling | Moves empty bottles to the line | Conveyor Belt |

| Filling | Dispenses a precise volume of product | Piston Filler |

| Capping | Applies and tightens caps securely | Automatic Capper |

| Labeling | Applies branding and traceability info | Automatic Labeler |

Ready to Optimize Your Bottling Operation?

Whether you're a commercial apiary packaging honey or a distributor supplying beekeeping equipment, the right bottling machinery is critical for efficiency and product quality. HONESTBEE supplies robust, precision-engineered beekeeping supplies and equipment, including bottling solutions designed for high-volume, consistent performance.

Contact HONESTBEE today to discuss how our wholesale-focused equipment can streamline your production line, reduce costs, and scale your business.

Visual Guide

Related Products

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Semi Automatic Round Bottle Labeling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic In-Line Flat Surface Labeling Machine

People Also Ask

- What types of caps can capping machines handle? Find the Right Solution for Your Bottling Line

- What are the main types of caps supported by bottle capping equipment? Threaded, Press-On, and Insertion

- What is the function of a capping machine in honey packaging? Secure Your Product Quality and Shelf Life

- What is the purpose of bottle capping equipment and what types are available? Professional Sealing Solutions

- What is the purpose of a bottle capping machine? Boost Efficiency and Ensure Product Integrity

- What are the different types of capping machines available? Choose the Right One for Your Production Scale

- Can you bottle honey right after extraction? Weighing Speed vs. Quality for Your Apiary

- What are the categories of bottle capping machines? Choose the Right Automation for Your Line