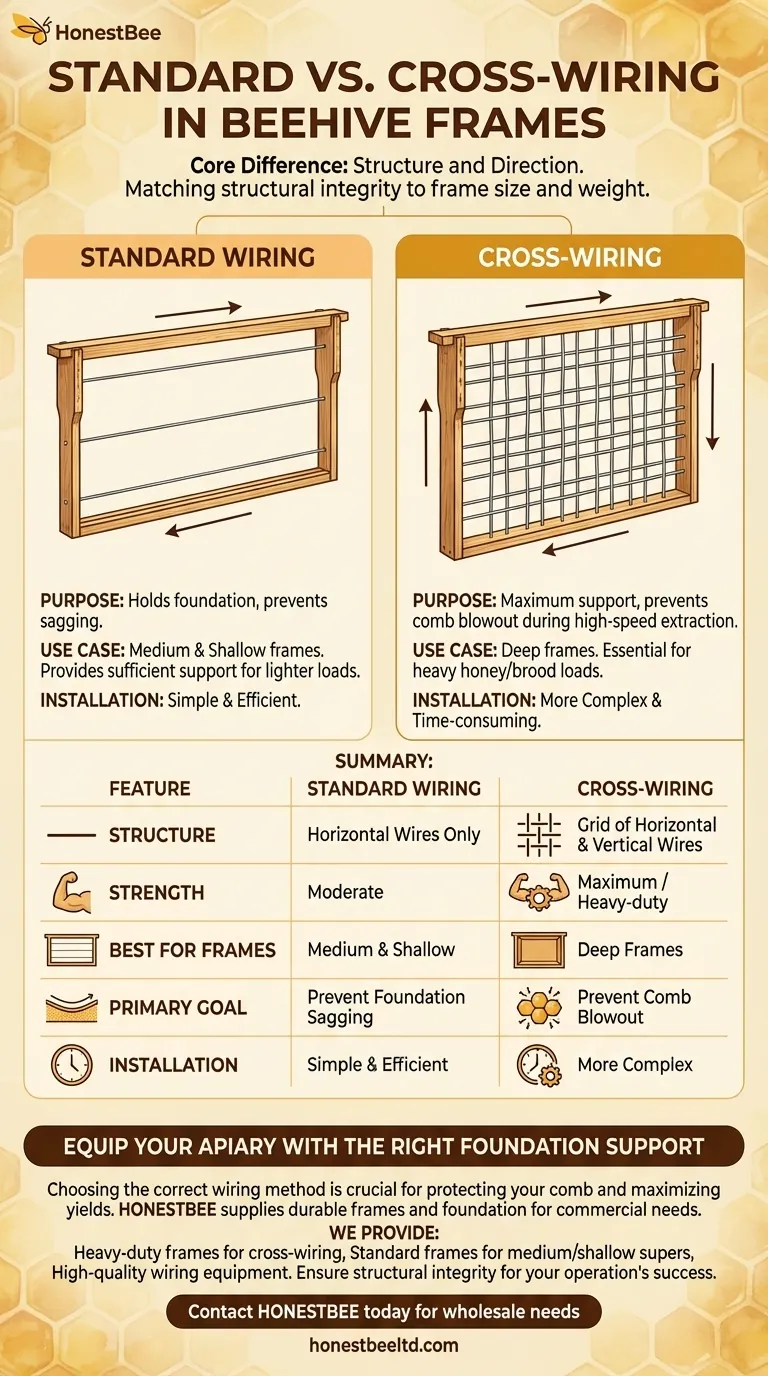

At its core, the difference between cross-wiring and standard wiring in a beehive frame is its structure and direction. Standard wiring typically involves running wires in a single direction (usually horizontally), while cross-wiring creates a robust grid by running wires both vertically and horizontally, with the wires intersecting at 90-degree angles.

The choice isn't about which method is universally better, but about matching the wiring's structural integrity to the specific size and weight demands of the frame. Cross-wiring is a specialized technique for providing maximum support to large, heavy frames.

The Purpose of Standard Wiring

Standard wiring is the most common method used by beekeepers for a reason: it's effective and efficient for the majority of frame sizes.

The Horizontal Support System

In a standard setup, wires are stretched horizontally across the frame from one side bar to the other. These parallel wires act as a simple but effective support structure.

Its Primary Goal

The main purpose of this wiring is to hold the sheet of wax or plastic foundation in place. It prevents the foundation from sagging under its own weight, the heat of the hive, or the initial weight of drawn-out comb.

Where It Is Sufficient

This method provides more than enough support for medium and shallow frames. The smaller surface area and lower potential weight of these frames do not require the over-engineering of a more complex system.

The Anatomy of Cross-Wiring

Cross-wiring is a heavy-duty solution designed to solve the structural challenges presented by the largest and heaviest frames in the hive.

A Two-Directional Grid

The defining feature of cross-wiring is the use of wires running in both vertical and horizontal directions. This creates a comprehensive grid pattern across the entire frame.

Creating an Intersecting Structure

To form this grid, the wires are often woven, alternating between running over and under the wires they cross. This interlocking design distributes forces evenly across the foundation.

The Goal: Maximum Integrity

This method provides exceptional strength and rigidity. The grid structure ensures that the wax foundation is supported against sagging, stretching, or breaking in any direction.

Understanding the Trade-offs

Choosing the right wiring method comes down to a simple cost-benefit analysis of effort versus need. Applying the wrong technique is either insufficient or unnecessary.

The Case for Cross-Wiring: Deep Frames

Cross-wiring is specifically recommended for deep frames. These frames hold significantly more honey and brood, making them exceptionally heavy. The immense force exerted during high-speed honey extraction can easily cause the comb to tear away from a frame with only standard wiring. The grid provides the necessary reinforcement to prevent this "blowout."

The Case Against It: Medium & Shallow Frames

Using cross-wiring on medium or shallow frames is not recommended. The additional time and effort to install a two-way grid are unnecessary, as standard horizontal wiring provides perfectly adequate support for these lighter frames.

Making the Right Choice for Your Goal

Select your wiring method based on the equipment you use and the results you need.

- If your primary focus is on deep frames for brood or honey: Cross-wiring is the superior choice to prevent comb damage and ensure frame longevity, especially if you use a radial extractor.

- If your primary focus is on medium or shallow honey supers: Standard horizontal wiring is the efficient and effective standard, providing all the support required.

Ultimately, choosing the correct wiring method is about providing the right amount of support for the specific job at hand.

Summary Table:

| Feature | Standard Wiring | Cross-Wiring |

|---|---|---|

| Structure | Horizontal wires only | Grid of horizontal & vertical wires |

| Strength Level | Moderate | Maximum / Heavy-duty |

| Best For Frame Sizes | Medium & Shallow frames | Deep frames |

| Primary Goal | Prevent foundation sagging | Prevent comb blowout during extraction |

| Installation Complexity | Simple & Efficient | More Complex & Time-consuming |

Equip Your Apiary with the Right Foundation Support

Choosing the correct wiring method is crucial for protecting your comb and maximizing honey yields. Whether you manage deep brood chambers or medium honey supers, HONESTBEE supplies the durable beehive frames and foundation to meet the specific needs of commercial apiaries and distributors.

We provide:

- Heavy-duty frames ideally suited for cross-wiring to handle deep frame loads.

- Standard frames with optimal support for medium and shallow supers.

- High-quality wiring and beekeeping equipment built for longevity and performance.

Ensure your frames have the structural integrity to support your operation's success. Contact HONESTBEE today to discuss your wholesale needs and get the right equipment for your hives.

Visual Guide

Related Products

- Stainless Steel Bee Hive Frame Wire for Beekeeping

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- HONESTBEE Professional Frame Wiring Board and Jig

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

People Also Ask

- What wire to use for bee frame? The Guide to Strong, Long-Lasting Frames

- What are some alternative materials for wiring beehive frames? Comparing Fishing Line vs. Stainless Steel

- Why is stainless steel frame wire recommended over galvanized wire? Ensure Honey Purity and Prevent Lead Contamination

- What specific type of hardware is used as a tie-off point for wire in beekeeping frames? Using 11/16 Inch Nails

- Why is wire sometimes threaded into foundationless frames? Ensure Comb Stability and Harvest Durability