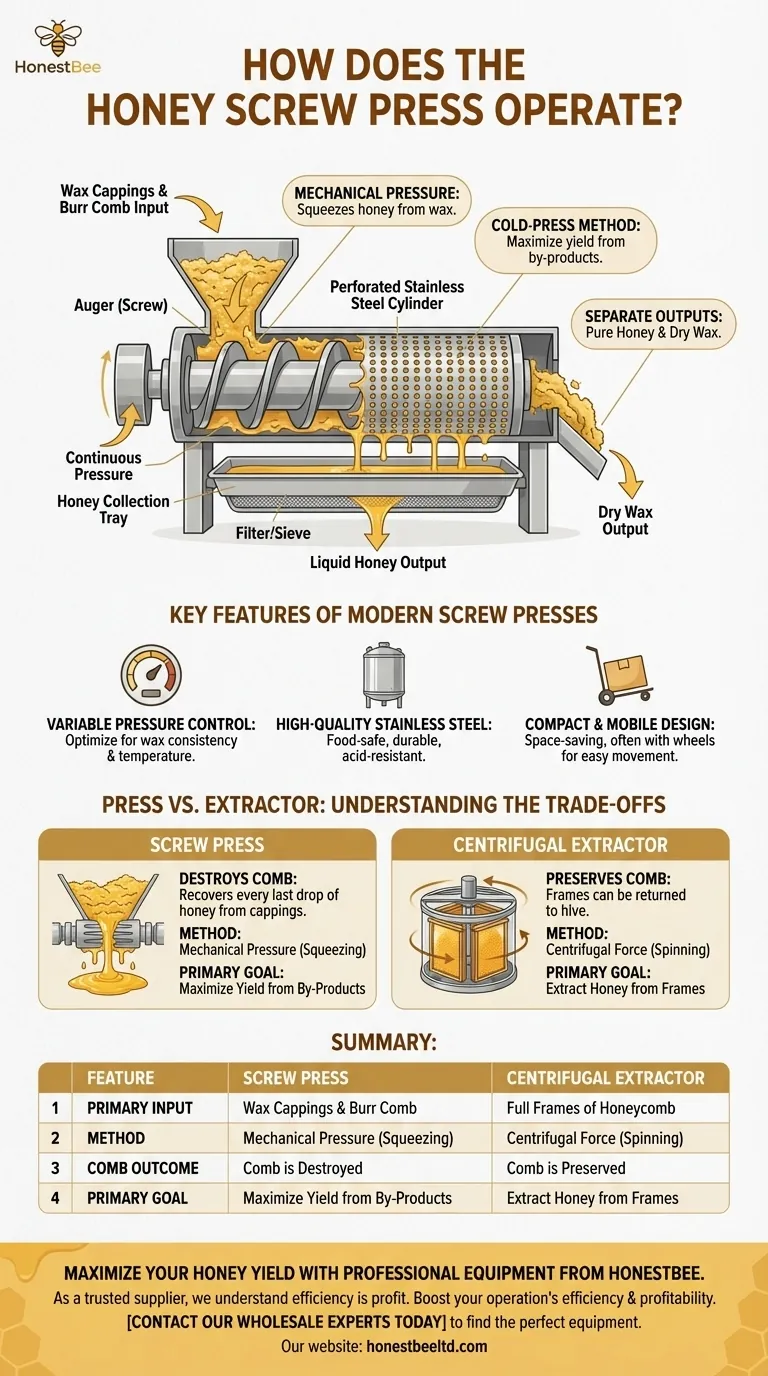

In essence, a honey screw press operates by mechanically squeezing honey from wax. It uses a large, rotating screw (an auger) inside a perforated cylinder to apply continuous pressure to honey-laden wax cappings. This force separates the liquid honey, which drains out through the perforations, from the wax, which is compacted and expelled at the end of the cylinder.

A honey screw press is not a primary honey extractor for full frames. It is a specialized tool designed to efficiently recover honey from wax cappings and burr comb using a cold-press method, maximizing your total honey yield.

The Core Mechanism: Cold Pressing in Action

To understand the value of a screw press, it’s crucial to visualize its simple yet effective mechanical process. It’s a machine built for a very specific task in the honey house.

The Input: Wax Cappings

The press is not designed for intact honeycomb frames. Its specific purpose is to process the wax cappings that are sliced off frames before they go into a standard centrifugal extractor, as well as any odd bits of burr comb.

The Squeezing Process

This honey-rich wax is fed into the press. A motor turns a large screw that slowly and powerfully pushes the material through a long, perforated cylinder. This continuous pressure forces the liquid honey out of the wax.

Separation of Outputs

As the honey is squeezed out, it permeates through the small holes of the cylinder body. It then drains downward, often through a built-in sieve, and is collected in a container below. The remaining wax, now highly compacted and dry, is pushed out the end of the cylinder into a separate receptacle, ready for melting and rendering.

Key Features of Modern Screw Presses

While the principle is simple, modern presses have features designed for efficiency and quality. Understanding these helps clarify their role in a professional or semi-professional operation.

Variable Pressure Control

Many models allow you to adjust the speed of the screw. This variable pressure control is critical for customizing the extraction process based on the consistency and temperature of your wax cappings to achieve maximum efficiency.

High-Quality Construction

These machines are typically made from high-quality, acid-resistant stainless steel. This is essential for food safety, durability, and ease of cleaning, given the acidic nature of honey.

Compact and Mobile Design

Most honey screw presses are designed to be relatively compact and are often equipped with wheels. This makes them suitable for small to medium-sized enterprises where space can be limited and equipment may need to be moved easily.

Understanding the Trade-offs: Press vs. Extractor

A common point of confusion is the difference between a honey screw press and a centrifugal honey extractor. They serve two entirely different, though complementary, purposes.

The Purpose of a Screw Press

A screw press destroys the comb to recover every last drop of honey. Its primary role is to process the cappings from your main extraction, significantly increasing your overall yield from what might otherwise be difficult to process.

The Purpose of a Centrifugal Extractor

A centrifugal extractor uses spinning force to fling honey out of the comb cells while leaving the comb itself intact. These empty frames of drawn comb can then be returned to the hive, saving the bees an enormous amount of energy.

Method of Separation

The screw press uses mechanical pressure (squeezing). A centrifugal extractor uses centrifugal force (spinning). They are fundamentally different tools for different stages of the honey harvesting workflow.

How to Apply This to Your Operation

Choosing the right equipment depends entirely on your specific goals and the scale of your beekeeping operation.

- If your primary focus is extracting honey from full frames while preserving the comb: A centrifugal honey extractor is the correct and necessary tool for the job.

- If your primary focus is maximizing your total honey yield by efficiently processing wax cappings: A honey screw press is the ideal, specialized addition to your workflow.

Ultimately, understanding the specific function of a honey screw press allows you to see it not as a replacement for an extractor, but as a powerful tool for achieving a more complete and efficient harvest.

Summary Table:

| Feature | Screw Press | Centrifugal Extractor |

|---|---|---|

| Primary Input | Wax Cappings & Burr Comb | Full Frames of Honeycomb |

| Method | Mechanical Pressure (Squeezing) | Centrifugal Force (Spinning) |

| Comb Outcome | Comb is Destroyed | Comb is Preserved |

| Primary Goal | Maximize Yield from By-Products | Extract Honey from Frames |

Maximize your honey yield with professional equipment from HONESTBEE.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we understand that efficiency is profit. Our high-quality, stainless steel honey screw presses are designed to help you recover every last drop of honey from your wax cappings, turning by-products into revenue.

Ready to boost your operation's efficiency and profitability?

Contact our wholesale experts today to find the perfect honey processing equipment for your business.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What are the operational characteristics of a basic manual honey press? Essential Guide for Artisanal Extraction

- What are the benefits of the Honey Press's gentle extraction method? Preserve Raw Honey Quality and Bee Welfare

- What is the purpose of the raised frame on the honey press? Simplify Logistics and Improve Extraction Workflow

- What is the recommended cleaning process for a honey press? Pro Tips for Wax Removal and Hygiene

- What are the recommended conditions for using a honey press? Achieve Optimal Honey Extraction

- How does an industrial honey pressing machine affect honey composition? Maximize Nutritional Density vs Extraction

- Why are honey presses indispensable for larger beekeeping operations? Scale Your Harvest with High-Volume Processing

- What happens to the remaining wax in the Wax Screw Presses set? A Guide to Efficient Honey & Wax Separation