In short, yes. A honey press is intentionally designed to be simple to operate, making it a highly accessible tool for beekeepers, particularly those with a small number of hives. The process relies on straightforward mechanical force, requiring you to load the honeycomb and turn a handle to squeeze out the honey.

A honey press offers an affordable and low-tech method for honey extraction. Its ease of use comes from a simple "crush and strain" mechanical process, but this simplicity comes at the cost of destroying the beeswax comb.

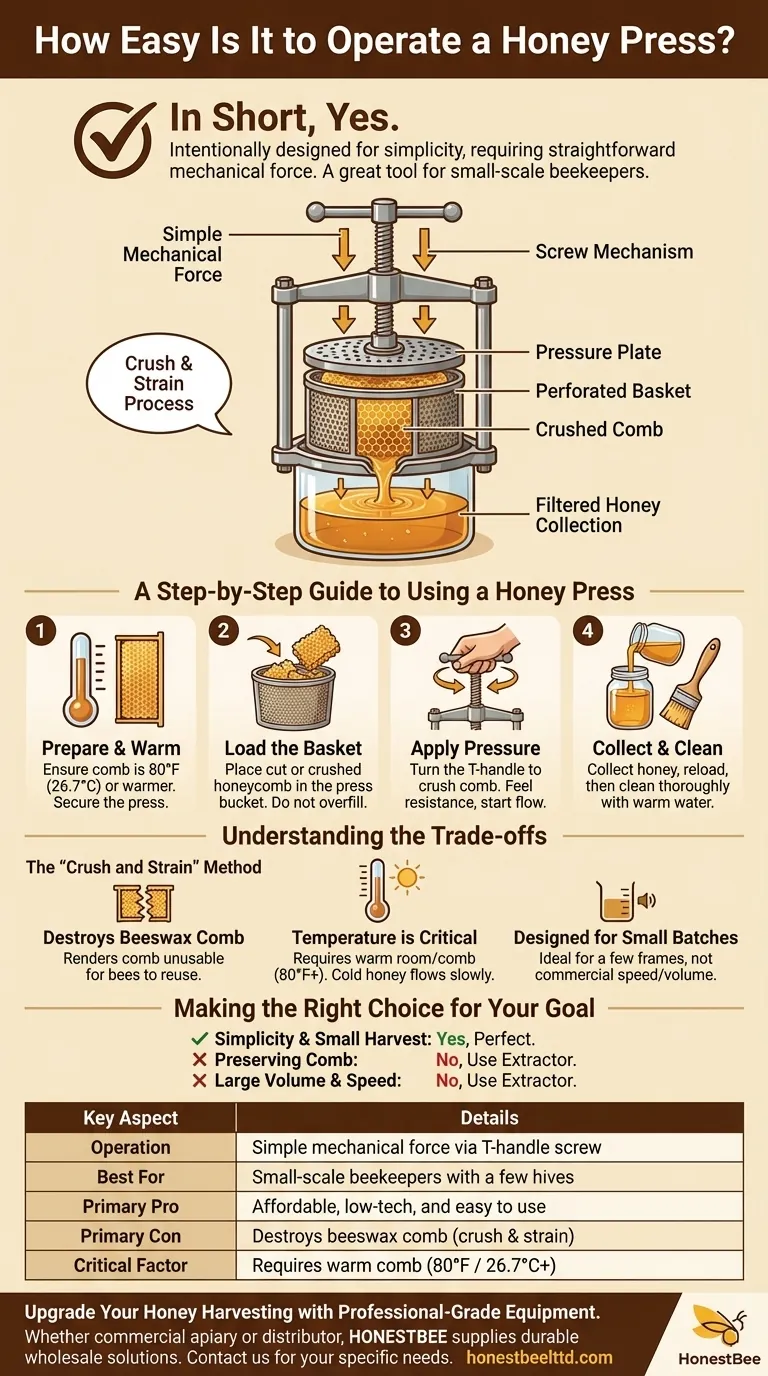

The Core Operating Principle: Simple Mechanical Force

A honey press is fundamentally a simple machine. Understanding its principle makes its operation intuitive.

How It Works

The device uses a screw mechanism, typically operated by a T-shaped handle. As you turn the handle, a pressure plate lowers onto the honeycomb placed within a perforated basket.

This action crushes the comb, squeezing the liquid honey out through the perforations while retaining the solid beeswax inside. The honey is then collected in a container placed underneath the press.

A Step-by-Step Guide to Using a Honey Press

While the concept is simple, following a clear process ensures you get the most honey with the least effort.

Step 1: Prepare Your Comb and Press

Before you begin, ensure your honeycomb is warm—ideally around 80°F (26.7°C) or warmer. Cold honey is thick and will not flow easily, making extraction difficult and inefficient.

For stability, bolt or clamp the press to a sturdy table or workbench. It can also be helpful to lightly crush the comb before loading it into the press.

Step 2: Load the Press Basket

Place your cut or crushed pieces of honeycomb into the inner press sieving bucket. Be mindful not to overfill it, as this can make pressing less effective.

Step 3: Apply Pressure

Engage the handle to set the pressure plate against the comb. Locate the main screw and tighten it until you feel resistance.

Rotate the T-shaped handle clockwise. This motion drives the pressure plate down, crushing the comb and starting the flow of honey.

Step 4: Collect the Honey and Reload

Continue turning the handle until the flow of honey slows to a drip. To maximize your yield, add more crushed comb to the press at least two or three times before emptying the spent wax.

The extracted honey, now separated from the wax, collects in your container below. It may contain fine wax particles, so you might choose to filter it further through a finer mesh or cheesecloth.

Step 5: Clean Up

Once you are finished, clean the press thoroughly with warm water and a soft nylon brush. Proper cleaning prevents buildup and ensures your equipment is ready for the next use.

Understanding the Trade-offs

A honey press is an excellent tool, but it's crucial to understand its primary trade-off compared to a centrifugal extractor.

The "Crush and Strain" Method Destroys Comb

The most significant factor to consider is that a press destroys your beeswax comb. The "crush and strain" method renders the comb unusable for the bees.

In contrast, a centrifugal extractor removes honey while leaving the drawn comb intact, which can be returned to the hive. This saves the bees an enormous amount of energy, as they don't have to rebuild the wax structure from scratch.

Temperature is a Critical Factor

The efficiency of a honey press is highly dependent on temperature. If your comb is below 70°F (21.1°C), the process will be extremely slow and yield will be low. Working in a warm room is not just a suggestion; it's a requirement for good results.

It's Designed for Small Batches

A press is ideal for processing honey from a few frames at a time. It is not built for the speed or volume required by commercial or large-scale beekeeping operations.

Making the Right Choice for Your Goal

Deciding if a honey press is right for you depends entirely on your beekeeping objectives.

- If your primary focus is simplicity and low-cost extraction for a small harvest: A honey press is a perfect, straightforward, and effective tool for the job.

- If your primary focus is preserving drawn comb for reuse in your hives: You must use a centrifugal extractor, as a honey press will destroy the comb.

- If your primary focus is processing large volumes of honey quickly: A honey press is not the right tool; you need the speed and capacity of a centrifugal extractor.

Ultimately, a honey press is an exceptionally easy-to-use device when you understand its purpose and operational requirements.

Summary Table:

| Key Aspect | Details |

|---|---|

| Operation | Simple mechanical force via a T-handle screw |

| Best For | Small-scale beekeepers with a few hives |

| Primary Pro | Affordable, low-tech, and easy to use |

| Primary Con | Destroys beeswax comb (crush & strain method) |

| Critical Factor | Requires warm comb (80°F / 26.7°C+) for efficiency |

Upgrade Your Honey Harvesting with Professional-Grade Equipment

Whether you're a commercial apiary scaling up or a distributor seeking reliable wholesale supplies, the right equipment is key to efficiency and yield. While a honey press is great for small batches, commercial operations need robust, high-capacity solutions.

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. We provide the durable tools you need to succeed.

Contact HONESTBEE today to discuss your specific needs and discover how our wholesale solutions can help your business thrive.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- What role does a high-pressure hydraulic press play in processing merva? Boost Your Wax Recovery Yield Today

- What role does pollen play in the quality of pressed honey? The Secret to a Creamy, Spreadable Texture

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping

- For which beekeeping methods are honey presses particularly useful? Expert Extraction Guide

- What is the function of the inner bucket in the honey press? Master the Art of Effective Honey Filtration

- Is it possible to separate beeswax from honey without specialized equipment? Simple Low-Tech Separation Guide

- What are the functions of mechanical honey presses and melting separation equipment? Optimize Your Honey Extraction

- How does the operational speed of the extruder affect the performance of a Wax Screw Press? Precision vs. Volume