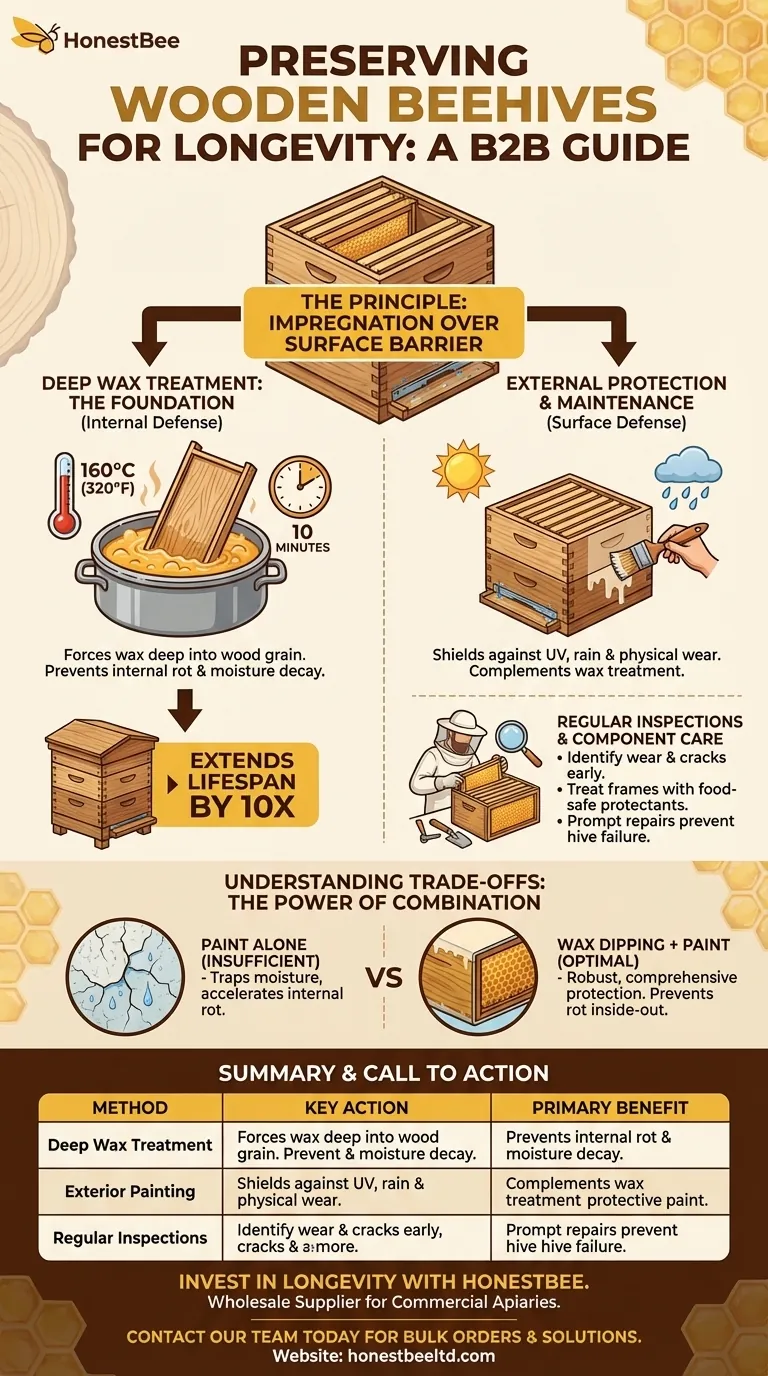

The most effective method for preserving wooden beehives involves a two-part process of deep treatment and external protection. The wood is first submerged in hot wax at approximately 160°C for about 10 minutes, which forces the wax deep into the pores of the wood. Afterward, the exterior of the hive is painted to provide an additional layer of weather resistance.

The core principle of hive preservation is not just about creating a surface barrier, but about impregnating the wood itself to prevent rot from the inside out, a strategy that can extend the life of your equipment by as much as ten times.

The Foundation of Longevity: Deep Wax Treatment

The primary method for dramatically increasing the lifespan of wooden hive components is a process often called wax dipping or cooking. This goes far beyond a simple surface coating.

How It Works

Submerging the wood in hot wax forces moisture out and draws the protective wax deep into the grain. This internal sealing is what provides long-term resistance to moisture and decay.

The Process

The standard practice involves heating wax to 160°C (320°F) and dipping the wooden components for around 10 minutes. This combination of temperature and time is critical for achieving full penetration.

The Primary Benefit

This single treatment is the most significant factor in preservation. By making the wood itself resistant to water, it can extend the lifespan of a hive by a factor of ten compared to untreated wood.

External Protection and Ongoing Maintenance

While wax dipping provides the internal defense, a complete preservation strategy also includes external protection and regular upkeep to handle the wear and tear of the seasons.

Adding a Layer of Paint

Painting the exterior of the hive adds another crucial barrier against sun and rain. This protects the wax-treated wood from the elements and further enhances its durability.

The Role of Regular Inspections

No preservation method lasts forever. Regular inspections are essential to identify components that are beginning to wear, crack, or show signs of rot before they fail completely.

Component-Specific Care

Frames also require attention. Treating wooden frames with food-safe wood protectants helps prevent both rot and warping, ensuring they remain functional for many seasons.

Understanding the Trade-offs

Choosing a preservation method involves understanding why certain steps are more effective than others. Simply painting a hive is not enough for maximum longevity.

Why Paint Alone Is Insufficient

Paint creates a surface barrier, but if any moisture gets behind it through a crack or joint, it can become trapped. This trapped moisture is a primary cause of wood rot, which paint can inadvertently accelerate.

The Power of Combination

Wax dipping prevents rot from the inside, while paint protects the exterior surface from UV degradation and physical wear. Using both methods in combination provides the most robust and comprehensive protection possible.

The Need for Prompt Repairs

The goal of maintenance is proactive intervention. Replacing damaged components promptly prevents a small issue, like a single rotting box, from compromising the integrity of the entire hive stack.

Making the Right Choice for Your Hives

Your approach to preservation should match your goals for equipment longevity and the level of investment you are willing to make.

- If your primary focus is maximum durability: The combination of deep wax dipping followed by exterior painting is the definitive, industry-proven method.

- If your primary focus is basic protection on a budget: At a minimum, apply several coats of high-quality exterior paint, ensuring the wood is completely dry beforehand.

- If your primary focus is ongoing hive health: Implement a schedule for regular inspections and be prepared to replace any components that show significant wear and tear.

Protecting your wooden equipment is a direct investment in the health of your colonies and the sustainability of your beekeeping operation.

Summary Table:

| Preservation Method | Key Action | Primary Benefit |

|---|---|---|

| Deep Wax Treatment | Submerge wood in 160°C wax for 10 minutes | Prevents internal rot, extends lifespan by 10x |

| Exterior Painting | Apply protective paint after wax treatment | Shields against UV, rain, and physical wear |

| Regular Inspections | Check for cracks, wear, and rot periodically | Proactive maintenance prevents hive failure |

Invest in the longevity of your apiary with HONESTBEE. As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we provide durable, wax-dipped hive components and professional-grade preservation supplies. Protect your investment and ensure colony health with equipment built to last. Contact our team today to discuss bulk orders and tailored solutions for your operation.

Visual Guide

Related Products

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

People Also Ask

- Why are oak or pine woods preferred for artificial beehives? Discover why these materials optimize colony health

- How do cement beehives compare to wooden beehives? Durability and ROI vs Traditional Methods

- What components are typically included in a wooden beehive set? A Complete Guide to Professional Hive Structures

- What is the best place to keep bees? Find the Perfect Apiary Site for Your Hives

- Why were wooden hives traditionally preferred? For Natural Beekeeping Aligned with Bee Biology