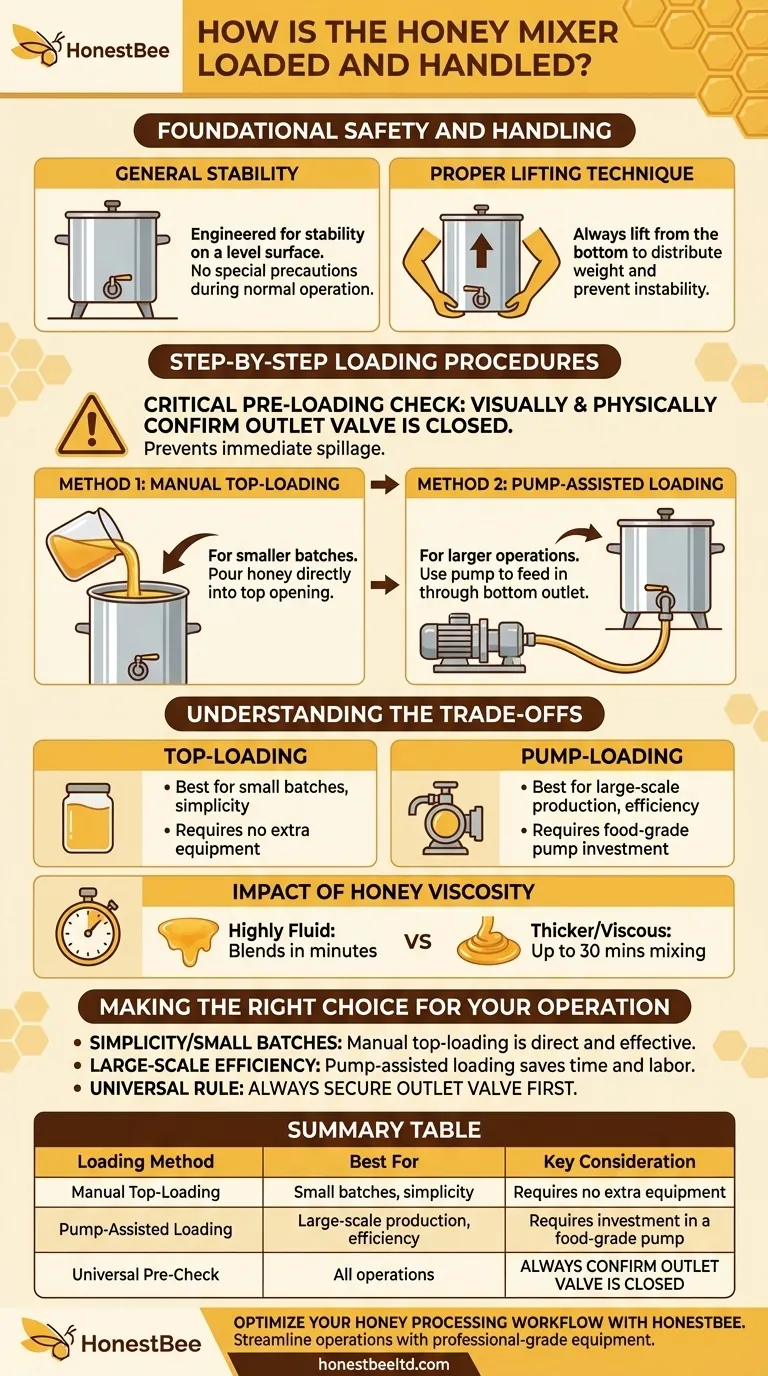

To load a honey mixer, you have two primary methods: pouring the honey directly into the top opening or using a pump to feed it in through the bottom outlet valve. Before loading with either method, the single most critical step is to ensure the outlet valve is fully closed to prevent any loss of product.

The process of handling and loading a honey mixer is fundamentally simple, but operational success hinges on one non-negotiable pre-flight check: always confirming the outlet valve is securely closed before introducing honey into the vessel.

Foundational Safety and Handling

Understanding the mixer's physical characteristics is the first step toward safe and effective operation. These machines are designed for stability, but proper technique is still essential.

General Stability

The honey mixer is engineered to be stable during normal operation and does not typically require special precautions during handling on a level surface.

Proper Lifting Technique

When lifting or moving the unit is necessary, always apply force from the bottom. Lifting from the base ensures the weight is distributed correctly and minimizes the risk of instability or damage.

Step-by-Step Loading Procedures

While the methods are straightforward, following a clear procedure prevents common and costly mistakes. The initial check is the most important part of the process.

The Critical Pre-Loading Check

Before adding any honey, always visually and physically confirm that the outlet valve is in the closed position. Overlooking this step will result in immediate spillage as soon as you begin to load.

Method 1: Manual Top-Loading

This is the most common method for smaller batches. Simply pour your honey batches directly into the large opening at the top of the cylindrical vessel.

Method 2: Pump-Assisted Loading

For larger or more automated operations, a pump can be used. Connect the pump's output hose to the mixer's outlet valve and pump the honey into the vessel from the bottom up.

Understanding the Trade-offs

The loading method you choose has direct implications for your workflow, efficiency, and equipment requirements.

Top-Loading vs. Pump-Loading

Manually pouring from the top is simple and requires no extra equipment, making it ideal for smaller operations. Pump-assisted loading is far more efficient for large volumes but requires an investment in a suitable food-grade pump.

The Impact of Honey Viscosity

Remember that loading is only the first step. The actual time required for blending is highly dependent on the honey's characteristics. Highly fluid honeys might blend in a few minutes, whereas thicker, more viscous types could require up to 30 minutes of mixing.

Making the Right Choice for Your Operation

Select your loading process based on the scale and efficiency goals of your specific task.

- If your primary focus is simplicity or small batches: Manual top-loading is the most direct and effective method.

- If your primary focus is large-scale production and efficiency: Using a pump to load via the outlet valve will save significant time and labor.

- Regardless of your method: Your first action must always be to secure the outlet valve to prevent spillage and product loss.

Following these fundamental procedures ensures safe handling and efficient use of your honey mixer from the very start.

Summary Table:

| Loading Method | Best For | Key Consideration |

|---|---|---|

| Manual Top-Loading | Small batches, simplicity | Requires no extra equipment |

| Pump-Assisted Loading | Large-scale production, efficiency | Requires investment in a food-grade pump |

| Universal Pre-Check | All operations | Always confirm the outlet valve is closed |

Optimize Your Honey Processing Workflow with HONESTBEE

Streamline your honey blending and bottling operations with professional-grade equipment from HONESTBEE. We supply durable, easy-to-handle honey mixers and a full range of beekeeping supplies designed for the demanding needs of commercial apiaries and beekeeping equipment distributors.

Our wholesale-focused operations ensure you get the reliable equipment you need to maximize efficiency and prevent costly product loss.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 10L Stainless Steel Electric Honey Press Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the technical advantages of using professional mixing equipment? Elevate Your Bee Product Quality

- Why must the heating temperature be strictly maintained below 56°C during the mixing of honey and plant-based raw materials?

- How does a mechanized honey whipping and creaming machine contribute to honey quality and value? Elevate Your Product.

- How is honey loaded into the mixer for processing? Master Manual and Pump-Driven Techniques

- Why are honey filtration and stirring systems essential? Elevate Your Product Quality for Global Export

- What role does high-shear homogenization play in composite royal jelly? Achieve Stability and Potency

- How does the honey mixer handle different types of honey? Master Viscosity for Perfect Blends

- What are the technical advantages of using an industrial electric mixer? Master DSM Sugar Patty Homogeneity