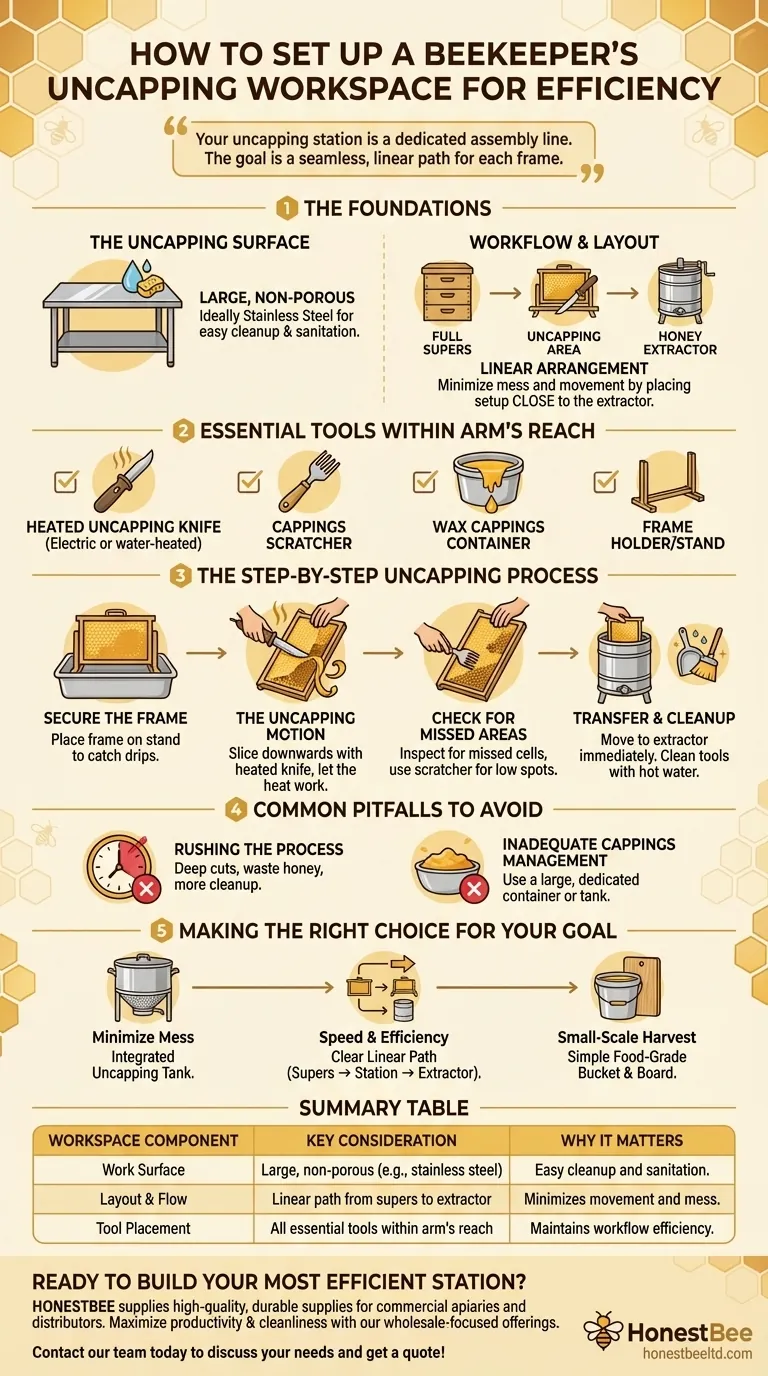

To properly set up your uncapping workspace, you need three things: a large, non-porous surface for easy cleanup, a logical arrangement of your tools, and close proximity to your honey extractor. This setup is designed to create an efficient workflow, minimizing mess and wasted movement during the harvest.

Your uncapping station is more than just a table; it's a dedicated assembly line. The goal is to create a seamless, linear path for each frame, moving it from the super to the extractor as cleanly and efficiently as possible.

The Foundations of an Effective Workspace

A successful honey harvest begins long before you touch a frame. It starts with a workspace designed for the specific, and often sticky, task of uncapping. The core principles are cleanliness, efficiency, and safety.

The Uncapping Surface

Your primary work surface is the foundation of the entire operation. It must be large enough to hold your supers, tools, and containers without feeling cramped.

The material is critical. Stainless steel is the ideal choice because it is non-porous, durable, and extremely easy to clean and sanitize. Food-grade plastic surfaces are also acceptable alternatives.

The Workflow and Layout

The physical arrangement of your station dictates your efficiency. Place your setup as close to the honey extractor as possible to streamline the transfer of uncapped frames.

Arrange your components in a logical line. A common flow is: full supers on one side, your uncapping area in the middle, and the extractor on the other side. This prevents you from having to turn around or walk across the room with dripping frames.

Essential Tools Within Arm's Reach

Keep your essential tools organized and immediately accessible. You should not have to stop and search for an item mid-process.

Your core toolkit includes an uncapping knife (electric or heated in water), a cappings scratcher for low spots, a dedicated container for the wax cappings, and a stand to hold the frame securely.

A Step-by-Step Process in Your Workspace

With your station prepared, the uncapping process itself becomes a simple, repeatable motion.

Securing the Frame

Place the frame on an uncapping stand or a simple board inside a larger tub. This holds the frame steady and ensures all dripping honey and wax are caught.

The Uncapping Motion

Begin with your heated uncapping knife. Start just below the top bar of the frame and slice downwards with a gentle, sawing motion. Let the heat of the knife do the work.

The goal is to remove only the wax cappings, leaving the honey-filled cells intact.

Checking for Missed Areas

After the main slice, inspect the frame for any sealed cells the knife missed, especially in low spots. Use a cappings scratcher or fork to puncture these remaining cappings.

Transfer and Cleanup

Immediately place the fully uncapped frame into the nearby extractor. Once the work is done, ensure all tools and surfaces are thoroughly cleaned with hot water to prevent attracting pests and to prepare for your next harvest.

Common Pitfalls to Avoid

Even a well-designed space can be undermined by a poor process. The primary trade-off you will manage is between speed and cleanliness.

Rushing the Process

Moving too quickly is the most common mistake. This leads to deep, uneven cuts that remove excessive honey with the cappings, increasing waste and the subsequent cleanup effort. A steady, deliberate pace is always more efficient in the long run.

Inadequate Cappings Management

Do not underestimate the volume of wax cappings you will produce. A small bowl is insufficient. Use a large, dedicated bucket or an uncapping tank to contain the cappings and allow the attached honey to drain.

Making the Right Choice for Your Goal

Your ideal setup depends on the scale of your operation and your primary objective.

- If your primary focus is minimizing mess: Invest in an integrated uncapping tank that holds the frame and strains the cappings in one unit.

- If your primary focus is speed and efficiency: Arrange your space in a clear, linear path: full supers -> uncapping station -> extractor -> empty supers.

- If your primary focus is a small-scale harvest: A simple food-grade bucket with a board across the top to hold the frame can be a perfectly effective and low-cost solution.

A well-planned workspace transforms honey harvesting from a sticky chore into a rewarding and seamless process.

Summary Table:

| Workspace Component | Key Consideration | Why It Matters |

|---|---|---|

| Work Surface | Large, non-porous (e.g., stainless steel) | Easy cleanup and sanitation. |

| Layout & Flow | Linear path from supers to extractor | Minimizes movement and mess. |

| Tool Placement | All essential tools within arm's reach | Maintains workflow efficiency. |

Ready to build your most efficient honey harvest station yet? At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable supplies needed for a seamless operation. From stainless steel uncapping tanks to professional-grade knives, our wholesale-focused offerings are designed to maximize your productivity and cleanliness. Contact our team today to discuss your needs and get a quote!

Visual Guide

Related Products

- Wide Adjustable Stainless Steel Honey Uncapping Fork with Scraper

- Stainless Steel Double Sided Honey Uncapping Fork with Scraper

- Stainless Steel Dual Blade Uncapping Plane

- Extra Wide Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

- Honeycomb Uncapping Knife for Apiculture

People Also Ask

- How does the depth of the honeycomb affect the choice of uncapping tool? Match the Right Gear for Maximum Efficiency

- What are the mechanisms and benefits of using filtration and settling tanks in honey processing? Boost Quality.

- What is the primary function of a stainless steel honey uncapping table? Optimize Your Honey Extraction Pretreatment

- How do high-precision filtering equipment and honey settling tanks contribute to product quality? Enhance Honey Purity

- How does a Honey Settling Tank improve the sensory quality of the final honey product? Ensure Clarity and Purity

- What role do settling tanks play in honey production? Achieve Pure, High-Clarity Honey Naturally

- What is a honey settling tank used for? Clarify Raw Honey Naturally & Preserve Quality

- How to use a honey settling tank? Clarify Your Honey for a Premium Finish