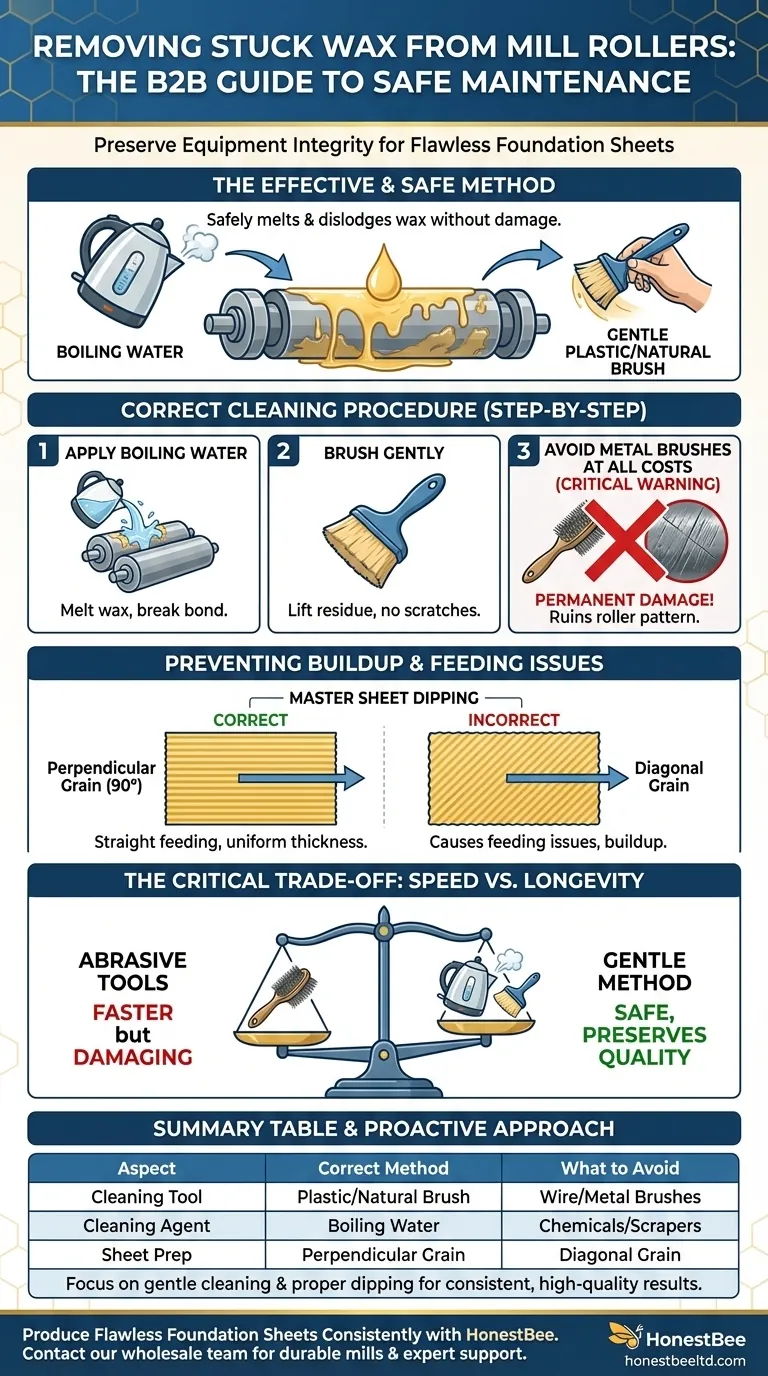

The most effective method for removing stuck wax from mill rollers is to use boiling water and a gentle brush. This approach safely melts and dislodges the wax without causing any damage to the delicate roller surfaces, which are critical for producing perfectly patterned foundation sheets.

The core challenge isn't just cleaning the wax, but preserving the integrity of your mill rollers. While the cleaning process is simple, understanding why wax builds up is the key to preventing future problems and ensuring high-quality production.

The Correct Cleaning Procedure

Proper cleaning is a straightforward process that requires heat, water, and the right tool. The goal is to melt the wax and gently wipe it away, not to scrape it off with force.

Step 1: Apply Boiling Water

Carefully pour boiling water directly over the rollers. The high temperature will quickly melt the wax, breaking its bond with the metal surface of the mill.

Step 2: Brush Gently

Using a plastic or natural animal bristle brush, gently scrub the rollers while the wax is melted. This will lift the residue away without scratching the roller pattern.

Step 3: Avoid Metal Brushes at All Costs

Never use a wire or metal brush. These abrasive tools will permanently scratch and damage the fine pattern on your rollers, which will transfer imperfections to every subsequent wax sheet you produce.

Preventing Wax Buildup and Feeding Issues

Stuck wax and feeding problems are often symptoms of an incorrect process. Properly prepared wax sheets should not cause significant buildup or operational issues.

The Importance of Sheet Dipping

The initial creation of the wax sheets is critical. When dipping, you must ensure the "grain" or ripples in the solidified wax run at a 90-degree angle to the sides of the sheet.

Identifying Incorrectly Made Sheets

If the ripples run diagonally across the sheet, it was dipped incorrectly. This is a primary cause of feeding issues.

The Goal: Straight Feeding

A correctly made wax sheet will feed straight through the rollers without skewing or listing to one side. This indicates the grain is properly aligned and the sheet has uniform thickness.

The Critical Trade-Off: Speed vs. Equipment Longevity

When faced with stubborn wax, it can be tempting to use a faster, more aggressive cleaning method. This is a significant mistake that prioritizes a short-term fix over the long-term health of your equipment.

The Lure of Abrasive Tools

Using a metal scraper or wire brush might seem to remove wax faster. However, this method will inevitably gouge the metal, destroying the precise pattern of the mill and ruining its ability to produce quality foundation.

The Value of the Gentle Method

The boiling water method may take slightly more time, but it has zero risk of damaging your equipment. Preserving the roller surface is essential for the quality of your output and the lifespan of the mill.

A Proactive Approach to Your Wax Mill

By focusing on both correct cleaning and proper operation, you can ensure consistent, high-quality results.

- If you are currently dealing with stuck wax: Use only boiling water and a soft-bristle brush to gently melt and remove the residue without damaging the rollers.

- If you want to prevent future issues: Master your sheet dipping technique, ensuring the wax grain runs perpendicular to the sides for smooth, straight feeding.

Ultimately, treating your wax mill with care is the foundation for producing perfect sheets every time.

Summary Table:

| Aspect | Correct Method | What to Avoid |

|---|---|---|

| Cleaning Tool | Plastic or natural animal bristle brush | Wire or metal brushes (causes scratches) |

| Cleaning Agent | Boiling water | Chemical solvents or aggressive scrapers |

| Sheet Preparation | Wax grain runs perpendicular to sheet sides | Diagonally aligned grain (causes feeding issues) |

| Primary Goal | Melt and gently wipe away wax | Scrape or force wax off |

Produce flawless foundation sheets consistently. The quality of your honeycomb starts with the quality of your equipment. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, high-performance foundation mills and the expert knowledge to maintain them. Let us help you optimize your production process. Contact our wholesale team today to discuss your equipment needs and ensure the longevity of your investment.

Visual Guide

Related Products

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Manual Spur Wheel Wire Embedder for Foundation

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Food Grade Plastic bee Foundation for Bee Frames

People Also Ask

- What is the role of a casting mould in the production of beeswax foundations? Essential Guide for Standardized Beekeeping

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- How does the measurement of wax foundation dimensions assist in honeybee study? Unlock Insights into Breed Evolution

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- What texture is embossed on the beeswax foundation machine? The Precise Worker Bee Cell Pattern for Hive Efficiency