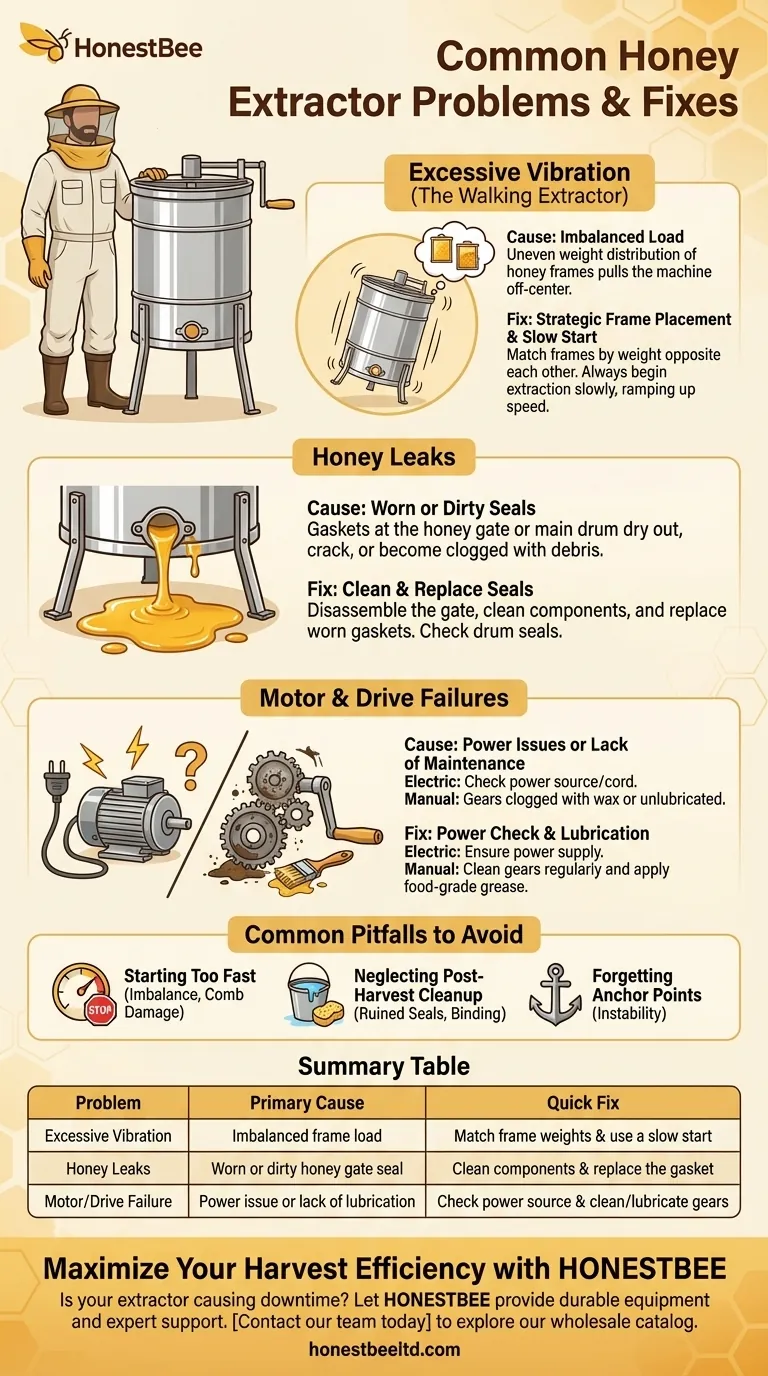

The most common honey extractor problems are excessive vibration, honey leaks, and motor or drive system failures. These issues almost always stem from a few core causes: imbalanced loads during operation, worn-out seals at connection points, and a lack of routine maintenance on mechanical parts.

The vast majority of extractor failures are not due to a defective machine, but to preventable operational errors. Understanding the principles of balance and the importance of post-harvest maintenance is the key to ensuring your extractor runs reliably for years.

Diagnosing Excessive Vibration (The "Walking" Extractor)

Violent shaking is the most frequent and alarming issue users face. If your extractor "walks" across the floor, the cause is almost always an imbalanced load.

The Root Cause: Uneven Weight Distribution

Honey frames are never perfectly uniform. A frame that is partially uncapped or has more honey on one side will create a significant weight imbalance when spun at high speeds.

This imbalance creates a centrifugal force that pulls the entire machine off-center, resulting in violent shaking and movement.

The Fix: Strategic Frame Placement

Before starting, try to match frames by weight. Place frames of a similar, heavy weight directly opposite each other in the basket. Do the same for lighter frames.

For radial extractors, this principle of symmetrical loading is just as critical. Distribute the frames evenly around the basket.

Best Practice: The Slow Start

Never start the extractor at full speed. Begin slowly, allowing some of the honey to be thrown from the combs. This initial extraction often helps to even out the weight distribution before you ramp up to higher speeds.

Addressing Honey Leaks

A puddle of honey under your extractor is a frustrating and wasteful problem. Leaks almost always originate from a compromised seal at the honey gate or the main drum.

The Honey Gate Seal

The most common leak point is the honey gate, or valve, at the bottom of the drum. This gate has a gasket or O-ring that can dry out, crack with age, or become compromised by debris like crystallized honey or beeswax.

The fix is straightforward: disassemble the gate, thoroughly clean all components, and replace the gasket if it shows any signs of wear.

The Main Drum Seal

Some extractors have a seal between the main stainless steel drum and the bottom plate. While more robust than the gate seal, this can also fail over time.

Replacing this seal is typically a more involved process that may require you to consult your extractor’s manual.

Troubleshooting Motor and Drive System Failures

When an electric extractor won't start or a manual one is difficult to crank, the issue lies in the power or drive system.

For Electric Models: Check the Power First

Before assuming the motor is dead, check the simple things. Ensure the power cord is firmly plugged in, check your building's circuit breaker, and inspect the cord itself for any damage.

If the power source is fine, listen to the motor. A humming sound without spinning may indicate a faulty capacitor, while a grinding noise suggests worn-out bearings.

For Manual Models: Clean and Lubricate Gears

Hand-crank extractors use a set of gears to generate speed. These gears can become clogged with wax and honey or simply run dry of lubrication.

Regularly clean the gears with a stiff brush and apply food-grade grease to keep the crank mechanism operating smoothly and prevent premature wear.

Common Pitfalls to Avoid

Proactive maintenance and proper technique will prevent nearly every common problem before it starts.

Mistake 1: Starting Too Fast

Ramping up to maximum speed immediately is the single fastest way to create a dangerous imbalance. This not only causes the machine to shake but can also damage the delicate wax combs in your frames.

Mistake 2: Neglecting Post-Harvest Cleanup

Allowing honey to crystallize on seals will ruin them. Failing to clean wax and debris from gears and moving parts will cause them to bind and wear out. A thorough cleaning with hot water after the harvest is not optional; it is essential maintenance.

Mistake 3: Forgetting the Anchor Points

If your extractor has holes in its legs, they are there for a reason. For any permanent or semi-permanent setup, bolting the extractor to a solid floor or a heavy wooden pallet provides the ultimate stability against vibration.

Making the Right Choice for Your Goal

Your approach to maintenance and operation should align with your primary goal as a beekeeper.

- If your primary focus is a smooth, efficient harvest: Meticulously balance your frames before every single run, and always ramp up the speed gradually.

- If your primary focus is long-term equipment reliability: Implement a strict post-season cleaning and maintenance schedule, including inspecting all seals and lubricating any gears.

- If you are troubleshooting a failure right now: Always begin with the simplest cause—check for an unbalanced load before assuming a seal has failed, and check the power source before assuming a motor is broken.

Ultimately, viewing your honey extractor as a precision tool that requires care, rather than a brute-force appliance, is the key to a trouble-free harvest.

Summary Table:

| Problem | Primary Cause | Quick Fix |

|---|---|---|

| Excessive Vibration | Imbalanced frame load | Match frame weights & use a slow start |

| Honey Leaks | Worn or dirty honey gate seal | Clean components & replace the gasket |

| Motor/Drive Failure | Power issue or lack of lubrication | Check power source & clean/lubricate gears |

Maximize Your Harvest Efficiency with HONESTBEE

Is your honey extractor causing downtime and reducing your yield? Let HONESTBEE, your trusted wholesale partner for commercial apiaries and distributors, provide the durable equipment and expert support you need. We supply high-performance extractors and replacement parts designed for heavy use, helping you avoid common failures and ensure a smooth, profitable harvest season.

Contact our team today to discuss your operation's needs and explore our wholesale catalog.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- How do you manually extract honey? Choose the Best Method for Your Hive

- What is the pressing method for extracting honey? A Simple, Low-Cost Approach for Small-Scale Beekeepers

- How to extract honey by hand? A Guide to Crush & Strain vs. Manual Extractors

- How much honey does a beekeeper extract from the hive? A Guide to Sustainable Harvesting

- How often do beekeepers collect honey? Maximize Your Hive's Sustainable Yield