To achieve efficient electric honey extraction, you must look beyond the extractor itself and optimize your entire workflow, from uncapping the frames to bottling the final product. True efficiency comes from creating a smooth, repeatable process where each step seamlessly feeds the next, preventing bottlenecks and minimizing manual effort. The speed of your electric extractor is only unlocked when the preceding and succeeding tasks can keep pace.

The central challenge of electric honey extraction isn't the speed of the machine, but the speed of the operator. Your primary goal should be to systematize the uncapping and handling of frames so the extractor is never sitting idle, waiting for the next batch.

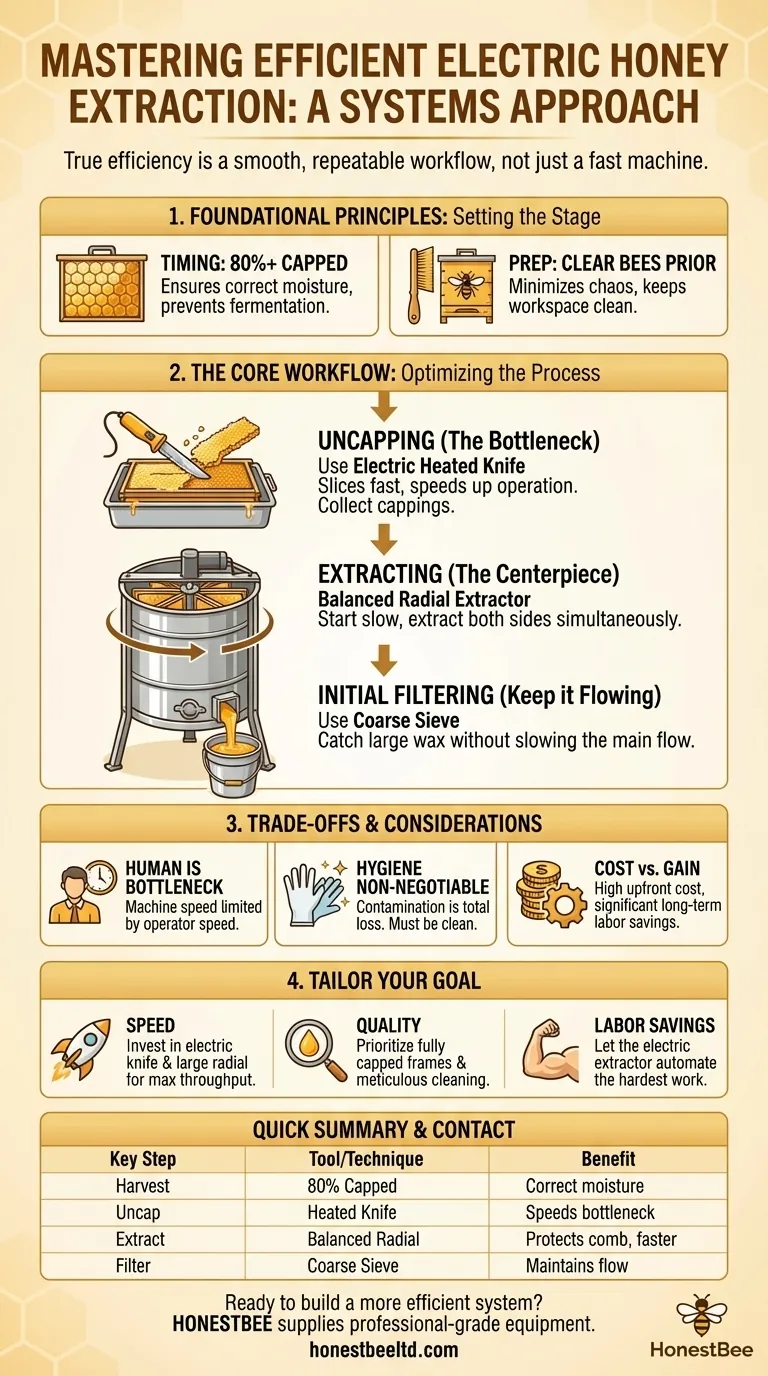

Foundational Principles: Setting the Stage for Success

Before you even turn on the extractor, two decisions will dictate the efficiency of your entire day. Getting these right prevents significant downstream problems.

Timing Your Harvest for Optimal Quality

The most crucial first step is to extract honey at the right time. Frames should be at least 80% "capped," meaning the bees have sealed the honeycomb cells with a layer of white wax.

Capped honey has the correct moisture content (under 18.6%). Harvesting uncapped, "wet" honey forces you into extra, time-consuming steps to prevent fermentation, completely undermining your efficiency.

Clearing Bees from the Hive

You must bring honey-filled frames, not bees, into your extraction space. Using a bee brush, a fume board, or a triangle escape board a day prior ensures your frames are clean and ready to go.

This preparation minimizes chaos and contamination in your processing area, allowing you to focus solely on extraction.

The Core of Efficiency: Your Extraction Workflow

With well-chosen frames in hand, your focus shifts to the three-part workflow: uncapping, extracting, and initial filtering. The electric extractor is the centerpiece, but its performance is dictated by the other two stages.

Optimizing the Uncapping Process

This is the most common bottleneck. An electric extractor can process frames far faster than most people can uncap them by hand. Your uncapping speed sets the pace for the entire operation.

To maximize throughput, use an electric heated uncapping knife. It slices through the wax cappings far more quickly and cleanly than a cold knife. Let the heated knife do the work; don't apply excessive pressure.

Collect these wax cappings in a dedicated uncapping tank or a bucket with a sieve. This allows honey to drain from the cappings while you continue working, reclaiming honey that would otherwise be wasted.

Leveraging Your Electric Extractor's Power

Properly loading the extractor is critical for smooth operation. Place frames of similar weight directly opposite each other to keep the drum balanced. An unbalanced load will vibrate violently and can shut off automatically or damage the machine.

Start the extractor on a low-speed setting. This allows some honey to be slung out, lightening the frames before you ramp up to higher speeds. This gradual acceleration prevents the delicate wax comb from "blowing out" under the initial weight of the honey.

If you have a radial extractor (where frames point outwards like spokes on a wheel), you gain a significant efficiency advantage. It extracts from both sides of the frame simultaneously, eliminating the need to stop and flip each frame halfway through.

Managing Cappings and Initial Straining

Do not let fine-filtering slow down your primary workflow. Position a coarse sieve or filter directly under the extractor's honey gate to catch large pieces of wax.

The goal is to get the bulk of the honey into a holding tank or bottling bucket. Fine filtering or settling can happen later, after the extraction work is complete.

Understanding the Trade-offs

An electric setup is an investment in efficiency, but it's important to be realistic about its limitations and requirements.

The Bottleneck Is Human

The machine is fast, but its potential is limited by your ability to uncap frames, load the drum, and manage the extracted honey. A fast extractor with a slow uncapping station is an inefficient system.

Cleanliness Is Non-Negotiable

Speed cannot come at the cost of hygiene. All equipment—from the uncapping knife to the bottling tank—must be meticulously clean. A contaminated batch represents a total loss of time, effort, and product, the ultimate inefficiency.

Upfront Cost vs. Long-Term Gain

Electric extractors and heated knives carry a higher initial cost than manual or crush-and-strain methods. The return on this investment is realized through significant labor savings, especially as your operation grows beyond a few hives.

Making the Right Choice for Your Goal

Your specific approach should be tailored to what you value most: speed, quality, or labor savings.

- If your primary focus is maximum speed and throughput: Invest in an electric uncapping knife and a large radial extractor to eliminate the two biggest time sinks.

- If your primary focus is preserving honey quality: Prioritize harvesting fully capped frames and maintaining impeccable cleanliness, even if it slightly slows your pace.

- If your primary focus is minimizing labor in a mid-size operation: The electric extractor itself is your key tool, as it automates the most physically demanding part of the process.

Ultimately, an efficient extraction process is a well-designed system where every tool and every action serves the goal of moving honey from the comb to the bottle with purpose and control.

Summary Table:

| Key Step | Tool/Technique | Efficiency Benefit |

|---|---|---|

| Harvest Timing | Extract when frames are 80% capped | Ensures correct moisture, prevents fermentation |

| Uncapping | Use an electric heated uncapping knife | Drastically speeds up the most common bottleneck |

| Extracting | Load a balanced radial extractor; start slow | Extracts both sides simultaneously, protects comb |

| Initial Filtering | Use a coarse sieve under the honey gate | Removes large wax without slowing the main workflow |

Ready to build a more efficient and profitable extraction system?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-performance tools needed for success. Our wholesale-focused operations provide reliable electric extractors, heated uncapping knives, and essential equipment to streamline your workflow, maximize your yield, and save valuable labor.

Contact HONESTBEE today to discuss your needs and get a quote on professional-grade extraction equipment.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What factors should be considered when choosing between an electric and manual honey extractor?

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors

- How have centrifuge honey extractors impacted honey harvesting? Boosting Efficiency and Sustainability