The primary advantages of a steam wax melter are its speed, its ability to produce high-quality, unburnt wax, and the minimal intervention required from the beekeeper during the process. It uses the power of hot steam to efficiently and gently separate pure wax from old honeycombs, making it a highly effective tool for beekeepers.

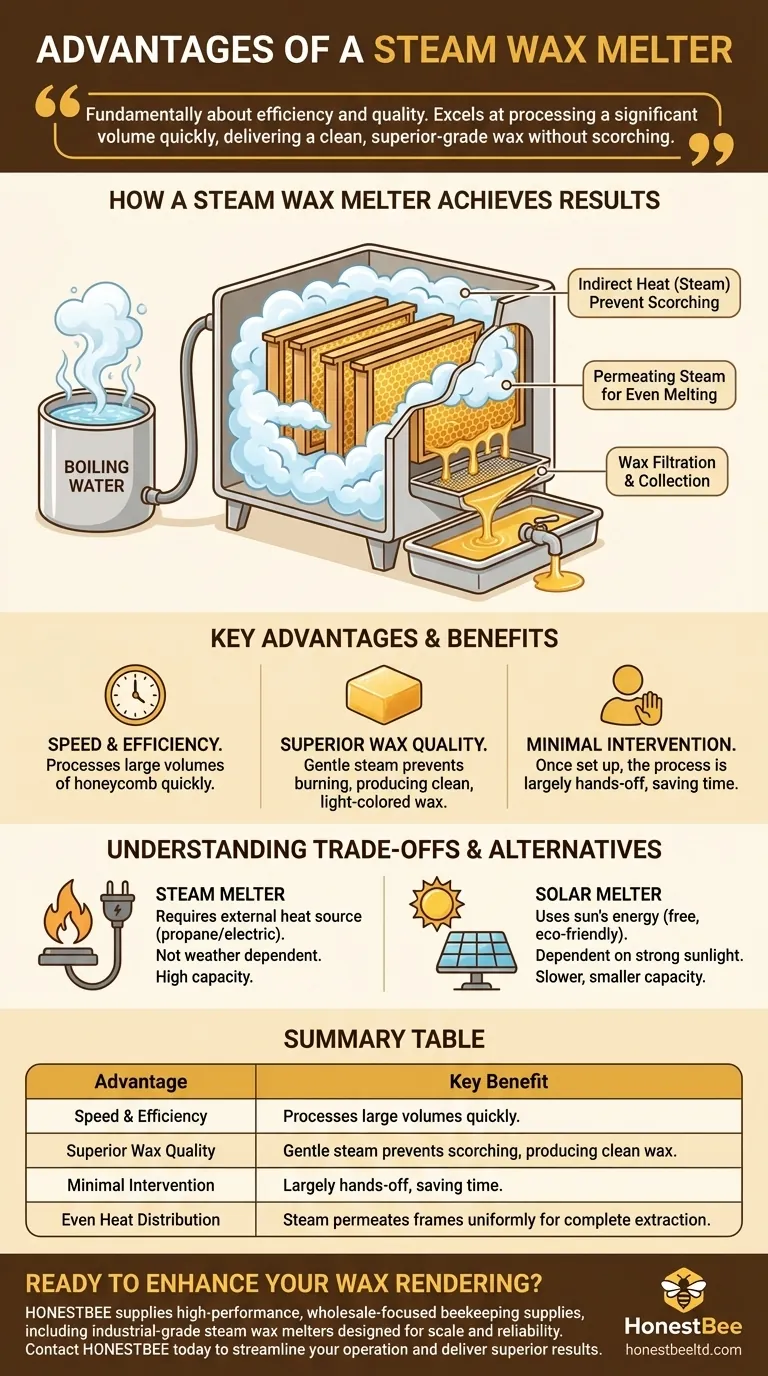

A steam wax melter is fundamentally about efficiency and quality. It excels at processing a significant volume of honeycomb quickly, delivering a clean, superior-grade wax without the risk of scorching that comes with direct heat methods.

How a Steam Wax Melter Achieves Its Results

A steam wax melter's advantages are a direct result of its well-thought-out design, which relies on indirect heat to perform its task.

The Principle of Indirect Heat

A steam melter works by boiling water in a separate, hermetically sealed container. This creates steam, which is then directed through a hose into the main chamber holding the frames.

This separation is critical. The wax is never exposed to a direct flame or a dry heating element, which prevents it from burning, darkening, or degrading in quality.

The Efficiency of Permeating Steam

Once inside the chamber, the hot steam envelops the frames completely. This ensures even and rapid heat distribution, melting the wax from all parts of the honeycomb simultaneously.

The liquid wax then flows through a filter mesh, which separates it from cocoons and other debris, before collecting on a pallet and draining through a tap.

Minimal Beekeeper Intervention

The process is remarkably hands-off. The beekeeper simply loads the frames, ensures the steam generator has water, and applies the heat source.

Once the system is running, it requires little to no monitoring beyond ensuring the process completes. This frees up valuable time for other apiary tasks.

Understanding the Trade-offs and Alternatives

While powerful, a steam wax melter is not the only option, and its benefits come with certain considerations.

The Need for a Heat Source

Unlike a solar melter, a steam melter requires an external heat source, such as a propane burner or an integrated electric heating element. This means it consumes energy and is not dependent on weather.

Comparison with Solar Melters

Solar wax melters are an excellent alternative, particularly for beginners or those with only a few hives. They use the sun's energy, making them environmentally friendly and free to operate.

However, they are entirely dependent on strong sunlight and are significantly slower than steam melters, processing a much smaller volume of wax at a time.

Capacity and Scale

Professional or larger-scale steam melters offer a significant increase in capacity, allowing a beekeeper to process dozens of frames in a single batch. This level of efficiency is essential for commercial or serious hobbyist operations.

Making the Right Choice for Your Operation

Choosing the correct rendering method depends entirely on the scale of your beekeeping and your primary goals.

- If your primary focus is processing many frames quickly: The speed and capacity of a steam wax melter are its greatest strengths.

- If your primary focus is achieving the highest quality, unburnt wax: The gentle, indirect heat of steam provides a consistent and superior result.

- If your primary focus is a low-cost, low-energy solution for a small apiary: A solar wax melter is an ideal and environmentally friendly starting point.

Ultimately, selecting the right tool is about matching the technology to the specific demands of your beekeeping operation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Efficiency | Processes large volumes of honeycomb quickly. |

| Superior Wax Quality | Gentle steam prevents scorching, producing clean, light-colored wax. |

| Minimal Intervention | Once set up, the process is largely hands-off, saving time. |

| Even Heat Distribution | Steam permeates frames uniformly for complete wax extraction. |

Ready to enhance your wax rendering efficiency and quality?

For commercial apiaries and beekeeping equipment distributors, the right equipment is key to productivity and profit. HONESTBEE supplies high-performance, wholesale-focused beekeeping supplies, including industrial-grade steam wax melters designed for scale and reliability.

Contact HONESTBEE today to discuss how our equipment solutions can streamline your operation and deliver superior results.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Thermostatic Conical Honey Melter

- 10L Stainless Steel Electric Honey Press Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What is the technical function of applying melted raw wax? Master Olfactory Induction for Faster Beehive Colonization

- What is done with the beeswax cappings after they are removed? Turn Your Hive Byproducts into Gold

- What should be done if melted beeswax starts to solidify? Tips for Re-melting and Workflow Management

- What is the purpose of applying natural beeswax to the surface of artificial 3D-printed honeybee cell boxes?

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures