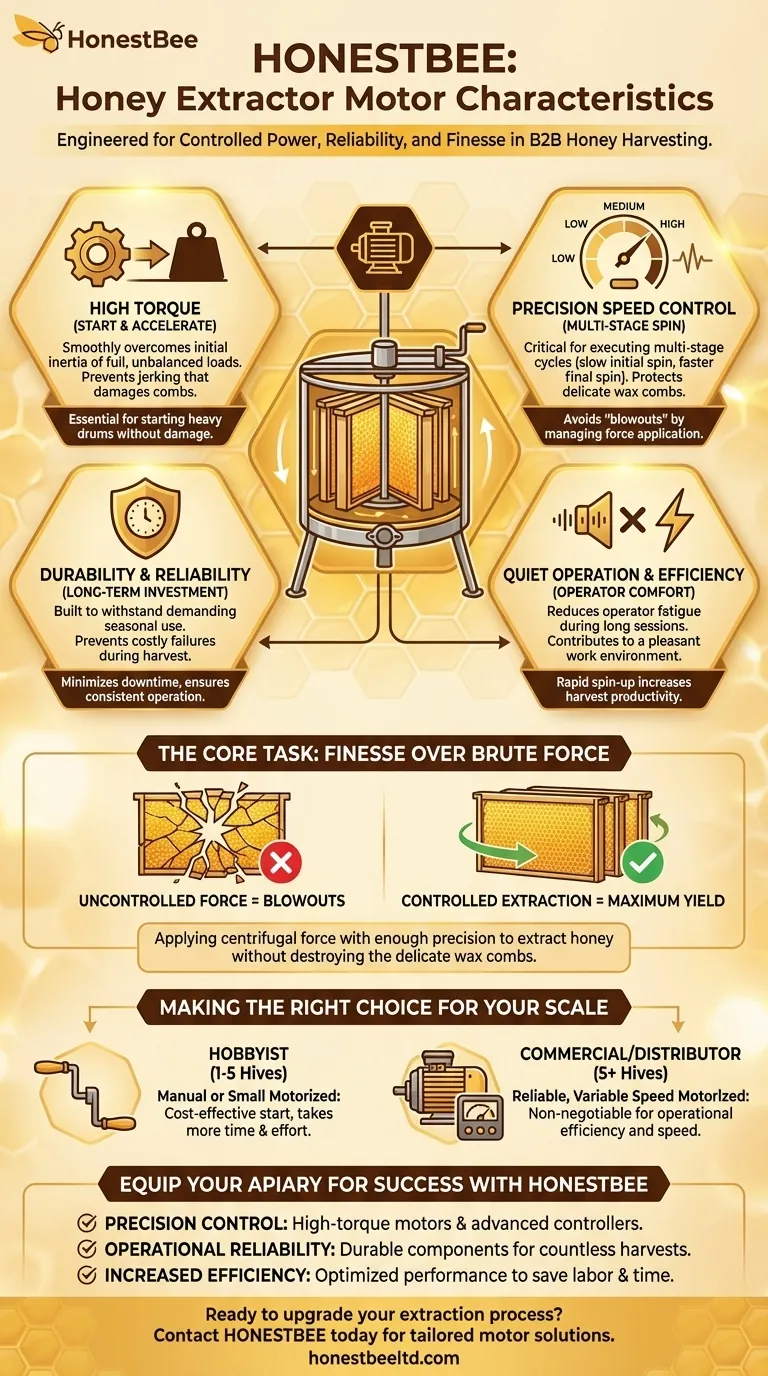

At their core, motors used in honey extractors are engineered for controlled power and reliability. The key characteristics are high efficiency for energy conservation, sufficient power (torque) to spin heavy frames, quiet operation, rapid spin-up, and exceptional durability to last through many harvest seasons.

The central challenge in honey extraction is not simply spinning frames, but applying centrifugal force with enough precision to extract honey without destroying the delicate wax combs. Therefore, the motor's most critical characteristic is not raw power, but its ability to be finely controlled.

Why Motor Characteristics are Critical

A honey extractor motor does more than just replace a hand crank. It is the heart of a system designed to maximize yield and minimize damage during the time-sensitive honey harvest.

The Core Task: Finesse Over Brute Force

Honey-filled frames are heavy and unbalanced. The wax comb itself is fragile. A motor that applies force too quickly or unevenly will cause a "blowout," where the weight of the honey shatters the comb structure against the far side of the frame.

The goal is to start slowly, allowing the bulk of the honey to be thrown from the cells, lightening the frame. Only then can the speed be increased to extract the remaining, more viscous honey.

The Role of Power and Torque

Power, specifically torque, is essential for overcoming the initial inertia of a full load of heavy frames. A motor must be powerful enough to start and accelerate the drum smoothly, even when it's unbalanced.

This ensures the extraction process begins without jerking, which could damage the combs or the extractor itself.

The Necessity of Precision Speed Control

Variable speed control is the most important feature of a modern motorized extractor. It allows the beekeeper to execute a multi-stage spin cycle.

A typical cycle involves a slow initial spin to clear about half the honey, followed by flipping the frames and repeating, and then a final, high-speed spin on both sides to finish the job. This methodical approach is impossible without a motor and controller system that offers precise RPM management.

Reliability and Quiet Operation

Honey harvesting is a demanding, seasonal activity. A motor failure during the harvest can be a significant setback. Durability and reliability are paramount, as these motors are long-term investments.

Quiet operation reduces operator fatigue during long extraction sessions and contributes to a more pleasant working environment.

Understanding the Trade-offs

Choosing a motorized system involves balancing cost, convenience, and capability. Not every motor is suitable for this delicate task.

Manual vs. Motorized

The primary trade-off is cost versus efficiency. A manual extractor is simple and inexpensive but requires significant physical effort and is slow.

A motorized extractor is a major investment but dramatically increases speed and reduces labor, making it essential for anyone with more than a few hives. It also provides the control needed to protect combs, a valuable asset for the bees.

Standard vs. Custom Motors

Most extractors use motors that are at least semi-customized. While a "standard" off-the-shelf motor might work, it often won't have the ideal mounting, power curve, or control integration.

Manufacturers select or design motors that fit specific extractor models, ensuring the power delivery is optimized for the drum size and capacity. This integration is a key part of what you pay for in a high-quality unit.

The Pitfall of Inadequate Control

Simply attaching any motor to an extractor is a recipe for disaster. A simple, single-speed AC motor, for example, would lack the torque at low speeds and would spin too fast once it got going, destroying the combs.

The "motor" in an extractor is truly a motor system, comprising the motor itself and a sophisticated electronic speed controller that manages its performance.

Making the Right Choice for Your Goal

Your decision should be guided by the scale of your beekeeping operation and your long-term goals.

- If your primary focus is hobby-level beekeeping (1-5 hives): A manual extractor is a cost-effective start, but a small motorized model will save you a great deal of time and protect your combs better.

- If your primary focus is sideline or commercial beekeeping (5+ hives): A reliable, motorized extractor with precise variable speed control is a non-negotiable tool for operational efficiency.

- If your primary focus is building or repairing an extractor: Prioritize a high-torque DC motor paired with a quality speed controller to ensure you have the necessary power and fine control for a multi-stage spin cycle.

Ultimately, investing in the right motor system protects the valuable honeycomb and ensures an efficient, successful honey harvest.

Summary Table:

| Key Characteristic | Why It Matters for Honey Extraction |

|---|---|

| High Torque | Smoothly starts and spins heavy, unbalanced frames without jerking. |

| Variable Speed Control | Enables multi-stage spin cycles to extract honey without damaging delicate wax combs. |

| Durability & Reliability | Withstands the demands of seasonal harvesting for long-term investment. |

| Quiet Operation | Reduces operator fatigue during long extraction sessions. |

| Rapid Spin-Up | Increases efficiency for a faster, more productive harvest. |

Equip Your Apiary for Success with HONESTBEE

Choosing the right motor is critical for protecting your valuable honeycomb and maximizing your harvest efficiency. For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies robust, high-performance motors and motor systems designed specifically for the demanding needs of honey extraction.

We provide wholesale-focused solutions that deliver:

- Precision Control: High-torque motors paired with advanced speed controllers for damage-free extraction.

- Operational Reliability: Durable components built to last through countless harvests.

- Increased Efficiency: Reduce labor and save time with motors engineered for optimal performance.

Ready to upgrade your extraction process? Contact HONESTBEE today to discuss motor solutions tailored for your scale and operational goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Vertical Motor Kits for 2 3 4 Frame Electric Honey Extractors

- Commercial 48-Frame Stainless Steel Honey Extractor

People Also Ask

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation

- How should an electric honey extractor be maintained and cared for? Protect Your Investment and Honey Purity

- Should I get a manual or electric honey extractor? Choose the right extractor for your beekeeping scale.

- How have centrifuge honey extractors impacted honey harvesting? Boosting Efficiency and Sustainability