Properly maintaining an electric honey extractor centers on a simple but critical rule: be meticulous with cleaning while being extremely cautious with its mechanical and electrical components. This involves thoroughly washing the drum and baskets with warm water immediately after use, but ensuring absolutely no water reaches the motor, bearings, or gearbox.

The core of electric extractor care is not complex mechanical servicing, but rather a disciplined cleaning routine. Your primary goal is to protect the sensitive motor and bearings from water and to prevent honey residue from hardening, which ensures both equipment longevity and the purity of your future harvests.

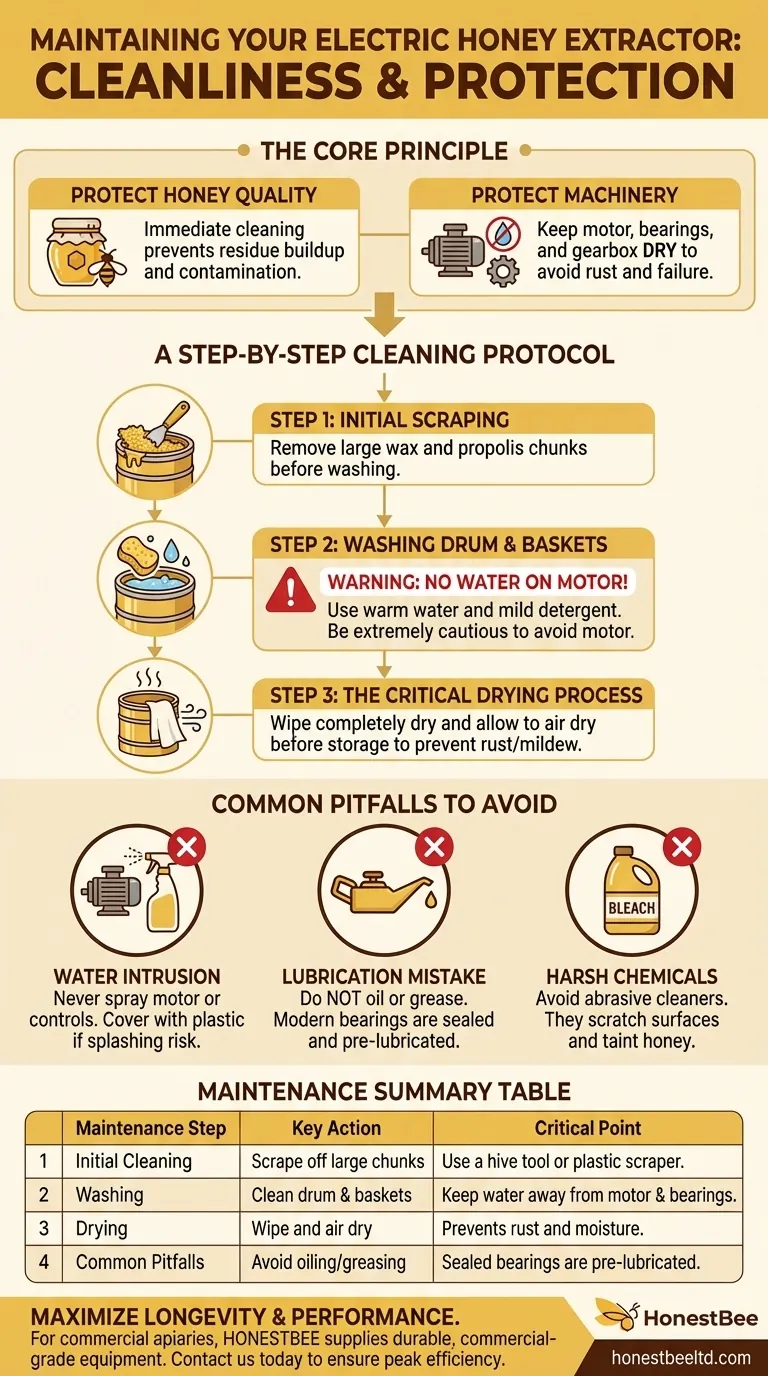

The Core Principle: Cleanliness and Protection

Understanding why you are performing certain maintenance steps is key to doing them correctly. The goal is twofold: protect the quality of your honey and protect the machinery from its biggest threats—water and neglect.

Why Immediate Cleaning is Non-Negotiable

Honey and wax that are left to dry inside an extractor become incredibly difficult to remove, almost like concrete.

Immediate cleaning with warm water melts and dissolves the residue easily. This also prevents the sticky mess from attracting ants, mice, and other pests during storage.

Protecting the Motor and Bearings

The primary difference between caring for a manual and an electric extractor is protecting the powered components.

Water intrusion into the motor, gearbox, or bearings is the fastest way to cause rust, electrical shorts, and catastrophic failure. These are the parts you must keep perfectly dry at all times.

A Step-by-Step Cleaning Protocol

Follow this simple process after every extraction session to keep your equipment in pristine condition.

Step 1: Initial Scraping

Before introducing water, use a hive tool or plastic scraper to remove any large chunks of wax and propolis from the interior drum and the baskets.

Step 2: Washing the Drum and Baskets

With the baskets still inside, use warm water and a soft cloth or sponge to wash the interior. A mild, food-safe detergent can be used to break down residues.

Some beekeepers use a pressure washer on a low setting, which can be effective but increases the risk of splashing water onto the motor. If you use this method, exercise extreme caution.

Step 3: The Critical Drying Process

Thoroughly rinse away all soap residue. Tip the extractor to drain all the water, then wipe the entire interior and all parts with a clean, dry cloth.

Allow the unit to air dry completely before reassembly or storage to prevent any chance of rust or mildew.

Common Pitfalls to Avoid

Correct maintenance is as much about what you don't do as what you do. Avoiding these common mistakes will save you significant trouble.

The Dangers of Water Intrusion

Never spray water directly onto the motor housing, control panel, or any area near the gearbox and bearings. Always cover these components with a plastic bag if there is any risk of splashing.

The Mistake of Lubrication

Do not oil or grease the extractor's moving parts. Most modern electric extractors use sealed bearings that are permanently lubricated.

Adding external lubricants can damage the seals, attract dirt and grime, and poses a significant risk of contaminating your honey.

Using Harsh Chemicals

Avoid abrasive cleaners or harsh chemicals. They can scratch stainless steel surfaces, creating areas for bacteria to grow, and can leave chemical residues that will taint your honey.

Making the Right Choice for Your Goal

Your maintenance routine should align with the scale of your beekeeping operation to ensure efficiency and reliability when you need it most.

- If your primary focus is hobby beekeeping: Diligent after-use cleaning and ensuring the unit is stored in a dry, pest-free location is the most important factor for long-term reliability.

- If you run a small-scale or sideline business: Standardize your cleaning protocol to make it fast and repeatable, and perform a quick mechanical and electrical check before the harvest season begins to prevent downtime.

Proper care protects your investment and ensures every batch of honey is as pure as the last.

Summary Table:

| Maintenance Step | Key Action | Critical Point to Remember |

|---|---|---|

| Initial Cleaning | Scrape off large wax/propolis chunks. | Use a hive tool or plastic scraper. |

| Washing | Clean drum and baskets with warm water. | Keep water away from the motor and bearings. |

| Drying | Wipe interior and air dry completely. | Prevents rust and ensures no moisture remains. |

| Common Pitfalls | Avoid oiling/greasing parts. | Modern extractors use sealed, pre-lubricated bearings. |

Maximize the longevity and performance of your extraction equipment. For commercial apiaries and distributors, reliable equipment is essential for a smooth, profitable harvest. HONESTBEE supplies durable, commercial-grade electric honey extractors and a full range of beekeeping supplies through our wholesale-focused operations. Contact our team today to discuss your equipment needs and ensure your operation runs at peak efficiency.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How does a tangential extractor work? Master the Art of Preserving Fragile Honeycombs

- How does a centrifugal honey extractor function to remove honey from frames? Expert Guide to Efficient Honey Harvesting

- How does professional industrial-grade honey extraction equipment impact production efficiency? Maximize Your Yield

- What are the technical advantages of using stainless steel honey extractors? Ensure Food Safety & Long-Term Durability

- How should a honey extractor be dried after washing? Pro Tips for Mold-Free Storage and Equipment Longevity

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What are the advantages and disadvantages of an electric honey extractor? Boost Your Apiary Efficiency

- What is the significance of the centrifugal honey extractor in industrial beekeeping? Maximize Yield & Purity