When assembling beehive frames, your primary considerations must be achieving a perfectly square structure and ensuring each corner is firmly nailed. The goal is to build a frame rigid enough to support the significant weight of honey, which can be around eight pounds per frame, without warping or breaking under load.

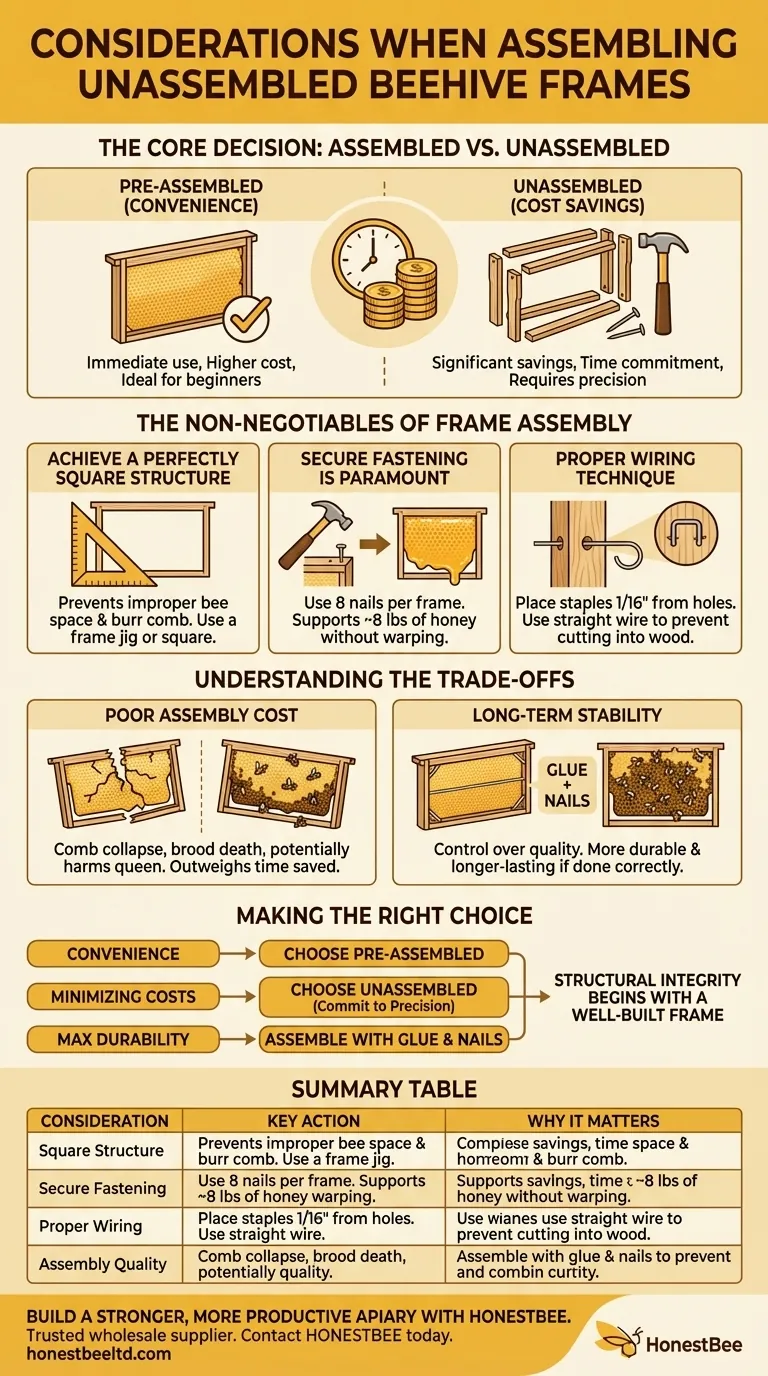

The decision between assembled and unassembled frames is a classic trade-off between time and money. While unassembled frames are more cost-effective, their value is entirely dependent on the quality of your assembly—a step where cutting corners can lead to catastrophic hive failure.

The Core Decision: Assembled vs. Unassembled

The first step is understanding why a beekeeper would choose to assemble their own frames. The benefits are clear, but they come with a significant responsibility.

The Cost Advantage

Unassembled frames are consistently cheaper to purchase than their pre-built counterparts. For beekeepers managing multiple hives, this cost savings can be substantial over time.

The Time Commitment

The trade-off for saving money is spending time. Assembling a single 10-frame hive box can require driving up to 80 nails. This task requires patience and precision, especially when repeated across several boxes.

The Non-Negotiables of Frame Assembly

If you opt for unassembled frames, the quality of your work is not just a matter of pride; it is essential for the health of your hive and the success of your honey harvest.

Achieving a Square and Rigid Structure

Each frame must be a perfect rectangle. A frame that is not square will not hang correctly in the hive body, creating improper bee space which can lead to unwanted burr comb and disrupt the colony's natural workflow.

Use a frame assembly jig or a simple carpenter's square to ensure every corner is a true 90-degree angle before you nail it.

Secure Fastening is Paramount

Use one or two nails in each corner for a total of up to eight nails per frame. Drive them firmly to create a tight, immovable joint. A loosely nailed frame will twist and fail under the weight of honey.

Proper Wiring Technique

For frames that require wire support for wax or plastic foundation, precision is key. Place your staples or eyelets approximately 1/16 of an inch from the wire holes. This small gap prevents the taut wire from cutting through the wood over time.

Before threading the wire, ensure it is straight. Pushing bent or kinked wire through the small holes is frustrating and time-consuming.

Understanding the Trade-offs

The most common mistake is underestimating the importance of careful assembly. The consequences of a poorly built frame are severe.

The Real Cost of Poor Assembly

A frame that collapses inside the hive can destroy a perfect comb of honey, kill the brood within it, and potentially harm the queen. The effort required to clean up such a mess far outweighs the time saved by rushing the assembly.

Time vs. Long-Term Stability

Pre-assembled frames offer immediate convenience and are an excellent choice for beginners or those short on time. However, by assembling your own, you gain complete control over the quality, often resulting in a more durable and longer-lasting product if done correctly.

Making the Right Choice for Your Apiary

Your decision should be based on your resources, skill, and goals.

- If your primary focus is convenience and a quick start: Choose high-quality, pre-assembled frames to get your hives operational immediately.

- If your primary focus is minimizing costs and you have the time to invest: Choose unassembled frames, but commit to the meticulous process of building them correctly.

- If your primary focus is maximum durability and control: Assembling your own frames with both wood glue and nails will create the most robust and long-lasting equipment for your apiary.

Ultimately, the structural integrity of your hive begins with a well-built frame.

Summary Table:

| Consideration | Key Action | Why It Matters |

|---|---|---|

| Square Structure | Use a frame jig or carpenter's square | Prevents improper bee space and burr comb |

| Secure Fastening | Use 1-2 nails per corner (up to 8 per frame) | Supports ~8 lbs of honey without warping |

| Proper Wiring | Place staples 1/16" from wire holes; use straight wire | Avoids wire cutting into wood over time |

| Assembly Quality | Prioritize precision over speed | Prevents comb collapse and hive damage |

Build a stronger, more productive apiary with HONESTBEE.

As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we understand that your success depends on durable, reliable equipment. Whether you choose our high-quality unassembled frames for cost-efficiency or our pre-assembled options for convenience, you get the precision and durability required for heavy honey production.

Let us help you equip your operation for maximum yield and longevity. Contact HONESTBEE today to discuss your wholesale needs and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- Professional Frame Comb Fork and Lifter for Efficient Handling

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Professional Wooden Requeening Frame for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What is the final step in wiring a frame? Secure Lasting Tension for a Durable Hive

- What is the advantage of a bee frame wiring jig? Drastically Speed Up Hive Preparation

- What are the arguments for and against wiring beehive frames? Balance Durability and Management Flexibility

- What specific type of hardware is used as a tie-off point for wire in beekeeping frames? Using 11/16 Inch Nails

- How do you use a bee frame wiring jig? Master Professional Tensioning for Stronger Hives