The primary benefits of using hive assembly machines are significant savings in time and labor, superior consistency in construction, and long-term cost efficiency. By automating the repetitive and physically demanding process of building hives, these machines allow beekeepers to produce a high volume of uniform, high-quality components far more quickly than is possible by hand.

The decision to use a hive assembly machine is not merely about saving time. It is a strategic choice to improve the fundamental quality of your equipment, which directly impacts hive health, operational efficiency, and your ability to scale your beekeeping practice.

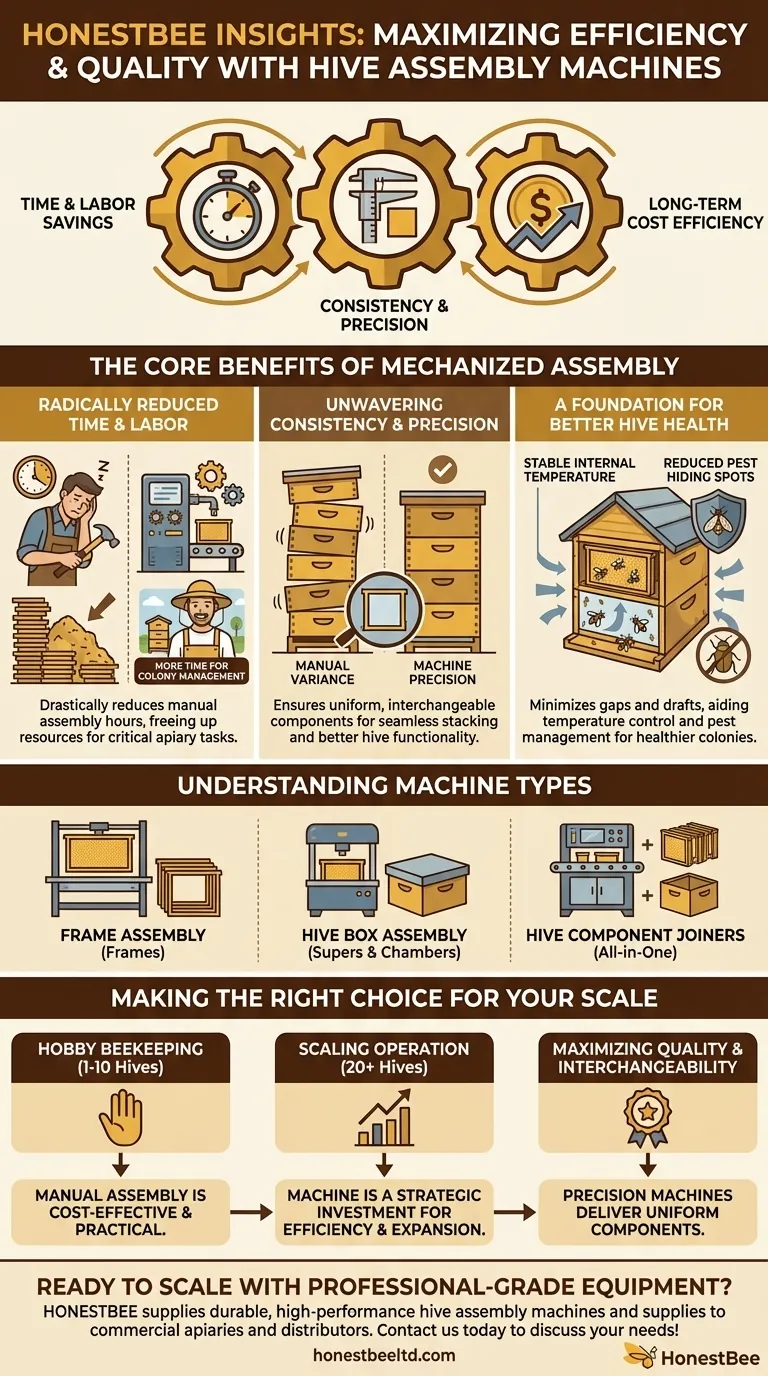

The Core Benefits of Mechanized Assembly

Automating hive construction moves a beekeeper's primary role from that of a carpenter to that of a colony manager. The benefits are felt across the entire operation, from the workshop to the apiary.

Radically Reduced Time and Labor

Constructing beehives by hand is a time-consuming and often strenuous task. A hive assembly machine drastically reduces the hours required for this work.

This recovered time is invaluable. It can be redirected toward more critical beekeeping activities like pest management, swarm prevention, and honey harvesting, which directly contribute to the success of the colonies.

Unwavering Consistency and Precision

Machines produce perfectly square boxes and uniformly assembled frames every single time. This level of consistency is difficult to achieve manually.

Uniformity is not just an aesthetic benefit. It ensures that hive components are interchangeable, stack perfectly without gaps, and that frames fit snugly within the boxes. This precision enhances the overall functionality of the hive.

A Foundation for Better Hive Health

The precision of machine-built hives directly contributes to healthier bees. Properly seated frames and gap-free boxes reduce drafts, which helps the colony maintain a stable internal temperature.

Furthermore, eliminating unwanted gaps and crevices denies pests like wax moths and small hive beetles ideal places to hide and reproduce, making integrated pest management more effective.

Understanding the Types of Hive Assembly Machines

The benefits you realize will depend on the type of machine you choose, as each is specialized for a different part of the construction process.

Frame Assembly Machines

As the name suggests, these machines are designed specifically to assemble the individual frames that hold the foundation or comb. They ensure each frame is square and securely fastened.

Hive Box Assembly Machines

These machines focus on constructing the wooden boxes (supers and brood chambers) that form the main structure of the hive. They are designed to securely join the box components, ensuring a durable and weather-resistant seal.

Hive Component Joiners

A hive component joiner is a more versatile, all-in-one solution. These machines are often capable of assembling both frames and boxes, making them a good option for beekeepers who want a single piece of equipment for all their construction needs.

Understanding the Trade-offs: Is a Machine Right for You?

While the benefits are clear, a hive assembly machine is not a necessary investment for every beekeeper. Objectively weighing the costs against your operational scale is critical.

The Upfront Investment

The most significant barrier is the initial cost. For a hobbyist managing only a handful of hives, the financial outlay for a machine is difficult to justify when components can be assembled manually in a reasonable amount of time.

The Scale of Your Operation

The decision hinges on scale. As a beekeeping operation grows, the time spent on manual assembly becomes a major bottleneck. For sideliners or commercial beekeepers who need to build or repair dozens or hundreds of hives, a machine quickly pays for itself in labor savings and increased productivity.

Maintenance and Workshop Space

Like any piece of machinery, hive assemblers require storage space and periodic maintenance. These are practical considerations that must be factored into the decision, particularly for those with limited workshop areas.

Making the Right Choice for Your Beekeeping Goal

Your decision should be guided by the specific goals and scale of your beekeeping operation.

- If your primary focus is hobby beekeeping (1-10 hives): Manual assembly is the most cost-effective and practical method for your needs.

- If your primary focus is scaling your operation (20+ hives): A machine is a strategic investment that unlocks efficiency and allows you to expand your apiary without being limited by construction time.

- If your primary focus is maximizing hive quality and interchangeability: The precision of a machine delivers perfectly uniform components that contribute to better hive health and easier management.

Ultimately, investing in a hive assembly machine is about shifting your focus from building equipment to building strong, healthy colonies.

Summary Table:

| Key Benefit | Description |

|---|---|

| Time & Labor Savings | Drastically reduces manual assembly time, freeing up resources for colony management. |

| Consistency & Precision | Produces uniform, interchangeable hive components for better functionality. |

| Improved Hive Health | Reduces gaps and drafts, aiding in temperature control and pest management. |

| Scalability | Enables efficient production of dozens to hundreds of hives for growing operations. |

Ready to scale your beekeeping operation with professional-grade equipment? HONESTBEE supplies durable, high-performance hive assembly machines and beekeeping supplies to commercial apiaries and distributors through wholesale-focused operations. Our equipment helps you build stronger colonies by ensuring consistent, high-quality hive construction. Contact us today to discuss your needs and boost your productivity!

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How do standardized beehives produced by professional manufacturing equipment contribute to colony health?

- How does industrial-grade beehive manufacturing machinery contribute to commercial apiaries? Scale Your Bee Business

- What is the technical value of industrial-grade hive manufacturing machinery? Support Colony Resilience and Biomimicry

- What role do hive-making machines play in the upstream beekeeping industry? Driving Standardization and Scale

- How do hive-making machines facilitate the scaling of stingless beekeeping operations? Achieve Commercial Scale

- How do hive assembly machines contribute to time savings? Boost Apiary Efficiency & Scale Your Operation

- What is the significance of professional hive-making tools? Scale Your Stingless Bee Farm with Precision Equipment

- What are the primary benefits of utilizing automated hive-making machines? Scale Your Apiary with Industrial Precision