The essential working process of a honey filling machine involves three primary stages: feeding the honey into the machine's reservoir, precisely positioning and filling the container under a nozzle, and finally, capping and sealing the filled container. This automated workflow is designed to handle the unique viscosity of honey while ensuring accuracy and hygiene.

The core purpose of a honey filling machine is not just to dispense honey, but to create a highly repeatable, efficient, and hygienic packaging system. This automation transforms a labor-intensive task into a precise process that guarantees product consistency and a professional finish.

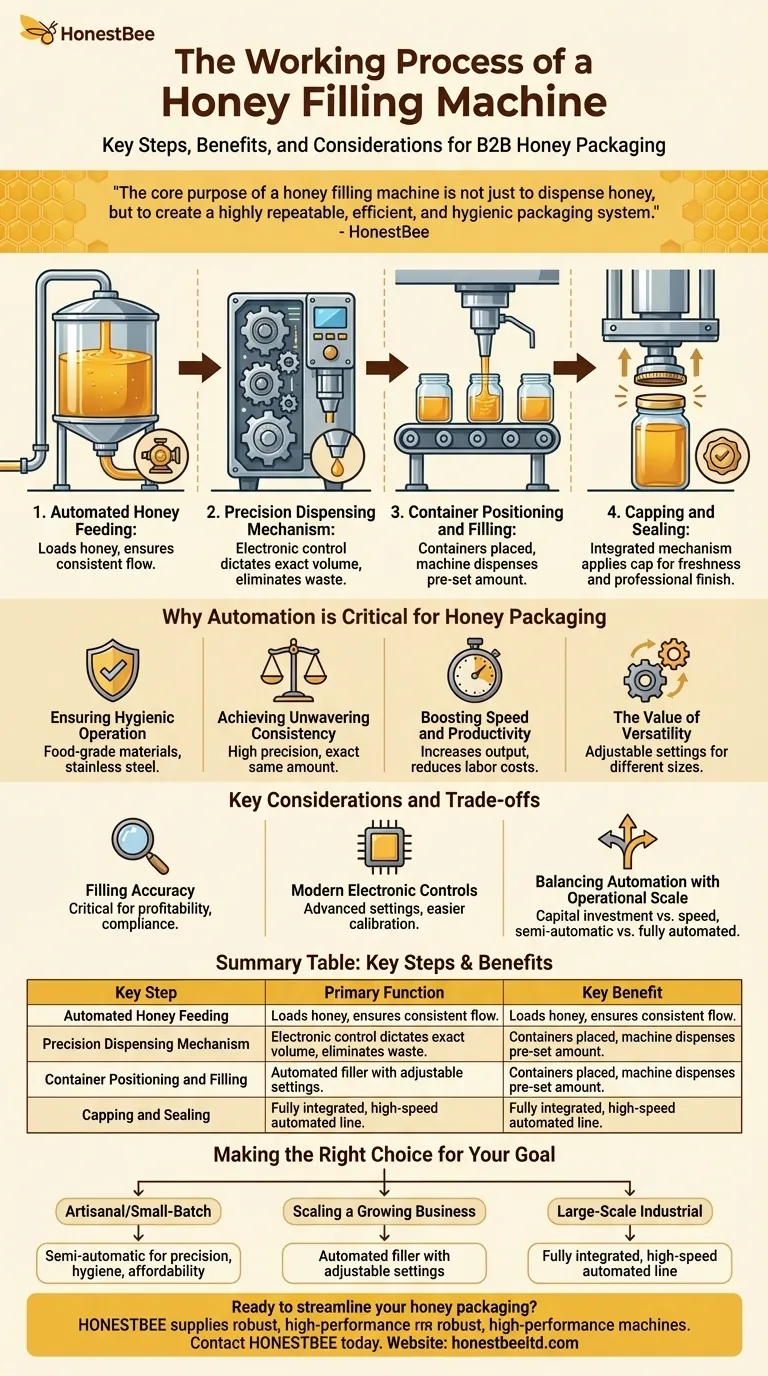

The Core Functions: A Step-by-Step Breakdown

A honey filling machine integrates several key functions into a streamlined workflow. Each step is engineered to address the specific challenges of packaging a viscous product like honey.

Automated Honey Feeding

The process begins by loading honey into the machine's holding tank or hopper. This system is designed to maintain the honey's quality and ensure a consistent, gravity-fed or pump-assisted flow to the dispensing mechanism.

Precision Dispensing Mechanism

This is the heart of the machine. An electronic control unit dictates the exact volume of honey to be dispensed in each cycle. This ensures that every jar is filled to the specified weight or volume, eliminating waste and ensuring customer satisfaction.

Container Positioning and Filling

Containers, such as jars or bottles, are placed under the filling nozzle. In semi-automatic machines, this is done manually, while fully automated systems use conveyors to move containers into the correct position. The machine then dispenses the pre-set amount of honey.

Capping and Sealing

Once filled, the container moves to the final stage. An integrated mechanism applies a cap and seals it tightly. This step is crucial for preserving the honey's freshness and providing a tamper-evident, professional-looking final product.

Why Automation is Critical for Honey Packaging

Automating the filling process provides significant advantages over manual methods, directly impacting product quality, operational efficiency, and brand perception.

Ensuring Hygienic Operation

Professional honey filling machines are constructed with food-grade materials, typically stainless steel. This design prevents contamination and ensures the packaging process complies with health and safety standards.

Achieving Unwavering Consistency

Manual filling often leads to variations in volume from one jar to the next. A machine performs the same action with high precision every time, guaranteeing that each customer receives the exact same amount of product.

Boosting Speed and Productivity

Automation dramatically increases the number of containers that can be filled in a given period. This significant boost in speed reduces labor costs and allows producers to scale their operations efficiently.

The Value of Versatility

Modern machines feature adjustable settings that allow operators to easily switch between different container sizes and volumes. This adaptability is essential for businesses that offer their product in various packaging formats.

Key Considerations and Trade-offs

While the benefits are clear, selecting the right machine requires understanding the features that truly matter for your specific operation.

The Importance of Filling Accuracy

The single most critical feature is filling accuracy. It directly impacts profitability by preventing overfilling and ensures compliance with industry regulations. An inaccurate machine can be a significant source of product loss over time.

The Role of Modern Electronic Controls

Newer generations of filling machines feature advanced electronic control units. These systems offer more sophisticated settings, easier calibration, and a more efficient workflow, allowing for fine-tuned control over the entire process.

Balancing Automation with Operational Scale

A fully automated line offers the highest speed but comes with a significant capital investment. A semi-automatic machine, which requires an operator to place jars, can provide the same precision and hygiene at a lower cost, making it a better fit for smaller producers.

Making the Right Choice for Your Goal

Your operational scale and business objectives should dictate your approach to honey filling automation.

- If your primary focus is artisanal quality and small-batch production: A semi-automatic machine offers the best balance of precision, hygiene, and affordability.

- If your primary focus is scaling a growing business: An automated filler with adjustable settings for various jar sizes is crucial for meeting increasing demand with efficiency.

- If your primary focus is large-scale industrial output: A fully integrated, high-speed automated line with electronic controls is necessary to maximize productivity and minimize per-unit labor costs.

Understanding these core principles empowers you to choose the right equipment to package your product safely, professionally, and efficiently.

Summary Table:

| Key Step | Primary Function | Key Benefit |

|---|---|---|

| Automated Feeding | Loads honey into a holding tank | Maintains quality & ensures consistent flow |

| Precision Dispensing | Dispenses exact volume per container | Eliminates waste & ensures product consistency |

| Capping & Sealing | Applies and secures the cap | Preserves freshness & provides a professional finish |

Ready to streamline your honey packaging with precision and efficiency?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, high-performance honey filling machines. Our wholesale-focused operations ensure you get the right equipment to guarantee hygienic operation, unwavering consistency, and a significant boost in productivity.

Contact HONESTBEE today to discuss your packaging needs and get a tailored solution for your business.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What is the step-by-step procedure for cleaning a honey bottling machine? A Full Guide to Food Safety

- How does the use of professional honey-filling machinery improve the commercial value of stingless bee honey?

- What technical advantages do automated honey-filling machines offer? Enhance Purity and Precision in Every Bottle

- What is the primary function of an automated honey-filling machine? Maximize Efficiency & Purity in Your Production Line

- How does a vacuum honey filler work? Master Precision Filling for Viscous Liquids

- What is the filling accuracy of an automatic honey filling machine? Achieve ±0.5% Precision for Your Apiary

- How do automatic quantitative filling systems ensure consistency in honey? Achieve Perfect Flavored Honey Precision

- How does a Semi-automated Machine differ from an Automatic Viscous Liquid Filling Machine? Key Differences Explained