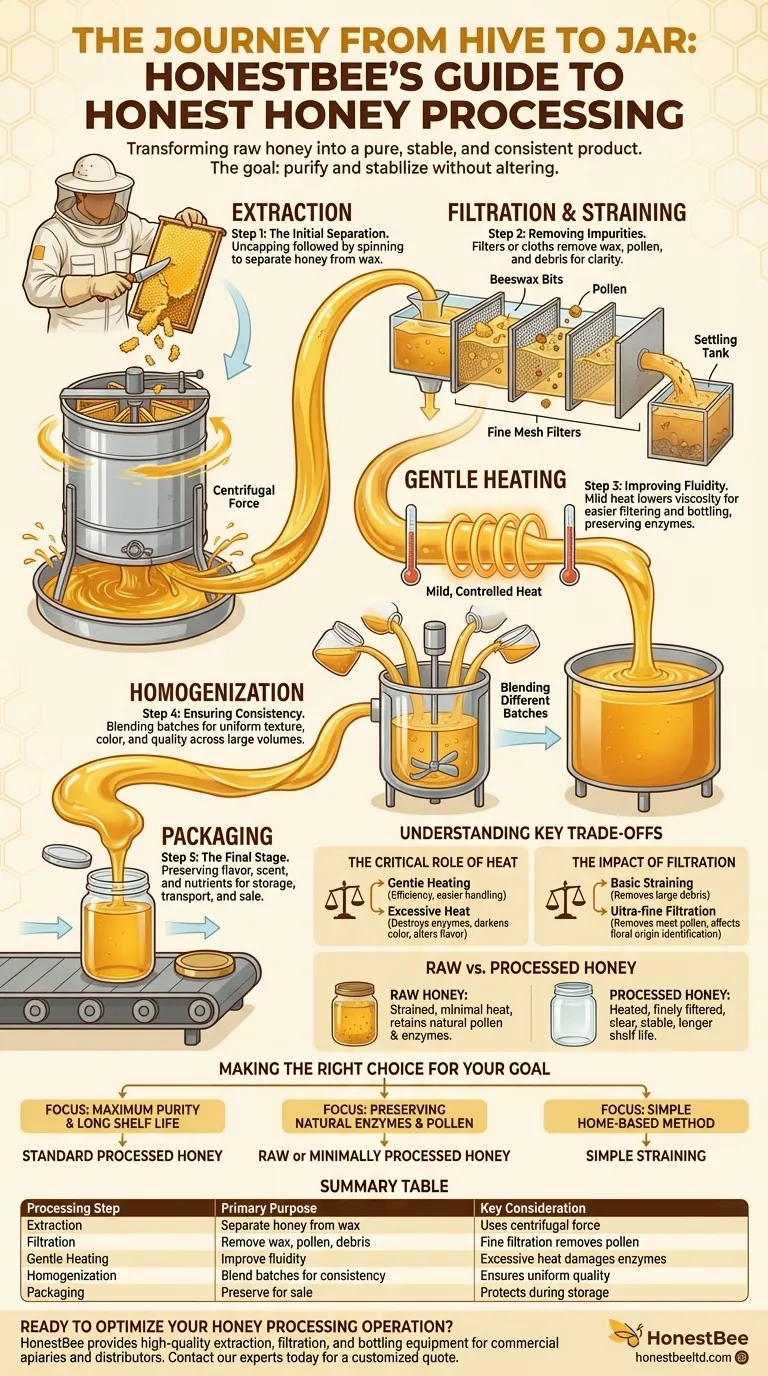

At its core, honey processing is a series of methodical steps designed to transform raw honey from the comb into a pure, stable, and consistent product. The main processes involved are extraction to separate honey from the wax, filtration to remove impurities, gentle heating to improve flow, homogenization for uniformity, and finally, packaging for distribution.

The fundamental goal of honey processing is not to alter the honey, but to purify and stabilize it. Each step is carefully controlled to remove unwanted materials like wax and debris while preserving the honey's natural flavor, nutrients, and aroma.

The Journey from Hive to Jar: A Step-by-Step Breakdown

Understanding each stage of honey processing reveals how raw, natural honey is prepared for safe and consistent consumption.

Step 1: Extraction - The Initial Separation

Before extraction, beekeepers uncap the honeycombs, removing the thin wax layer that seals the honey into the cells.

The combs are then placed into a machine called a honey extractor. This device uses centrifugal force, spinning at high speeds to sling the honey out of the comb and away from the wax without damaging the comb itself.

Step 2: Filtration & Straining - Removing Impurities

The extracted honey contains various particles, including bits of beeswax, pollen, and other hive debris.

To remove these, the honey is passed through filters or straining cloths. These are often fine nylon or metal meshes that catch visible impurities, resulting in a clearer final product. In some systems, the honey first sits in a settling tank to allow larger particles to rise to the surface for removal.

Step 3: Gentle Heating - Improving Fluidity

Raw honey is often thick and viscous, which makes it difficult to filter and bottle efficiently.

Processors may apply mild, gentle heat to the honey. This temporarily lowers its viscosity, allowing it to flow more easily through filters and into containers without degrading its natural enzymes or altering its delicate flavor.

Step 4: Homogenization - Ensuring Consistency

Large-scale operations often process honey from many different hives or sources.

Homogenization involves blending these different batches of honey together. This ensures that every jar has a consistent texture, color, and quality, meeting consumer expectations.

Step 5: Packaging - The Final Stage

The final step is packaging the clean, pure honey into jars or other containers.

This crucial stage is designed to preserve the honey's flavor, scent, and nutrients while preparing it for storage, transport, and sale.

Understanding the Key Trade-offs

While processing ensures a pure and stable product, the methods used involve important considerations that affect the final characteristics of the honey.

The Critical Role of Heat

Heat is a tool for efficiency, but it must be managed carefully. Gentle heating makes honey easier to work with.

However, excessive heat can destroy beneficial enzymes and vitamins naturally present in honey, and it can also darken the color and alter the flavor profile.

The Impact of Filtration

Filtration is essential for removing unwanted debris. The level of filtration is a key differentiator.

While basic straining removes large particles, ultra-fine filtration can also remove most of the pollen. Since pollen is often used to identify a honey's floral origin, its removal can be a downside for consumers seeking specific honey types.

Raw vs. Processed Honey

The primary difference between "raw" and commercially processed honey lies in these steps.

Raw honey is typically strained but not finely filtered or heated significantly, leaving natural pollen and enzymes intact. Processed honey undergoes heating and finer filtration to ensure clarity, stability, and a longer shelf life before crystallization.

Making the Right Choice for Your Goal

Selecting the right type of honey depends entirely on your priorities for its use and characteristics.

- If your primary focus is maximum purity and a long shelf life: Standard processed honey is your best choice, as it's filtered to remove all debris and heated to delay crystallization.

- If your primary focus is preserving natural enzymes and pollen: Seek out honey labeled as "raw" or "minimally processed," which avoids fine filtration and high heat.

- If your primary focus is a simple, home-based method: Simple straining through a cheesecloth or net is an effective way to clean honey from your own hives without complex equipment.

Ultimately, understanding the processing journey empowers you to choose the honey that perfectly aligns with your needs.

Summary Table:

| Processing Step | Primary Purpose | Key Consideration |

|---|---|---|

| Extraction | Separate honey from wax comb | Uses centrifugal force in an extractor |

| Filtration | Remove wax, pollen, and debris | Fine filtration can remove pollen, affecting traceability |

| Gentle Heating | Improve fluidity for bottling | Excessive heat can damage natural enzymes and flavor |

| Homogenization | Blend batches for consistent quality | Ensures uniform color and texture across large volumes |

| Packaging | Preserve flavor and nutrients for sale | Protects honey during storage and transport |

Ready to optimize your honey processing operation?

As a trusted supplier to commercial apiaries and distributors, HONESTBEE provides the high-quality, durable extraction, filtration, and bottling equipment you need to ensure efficiency and preserve honey quality at scale. Our wholesale-focused operations are designed to support your business's growth and consistency.

Contact our experts today to discuss your specific equipment needs and receive a customized quote.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How often do beekeepers collect honey? Maximize Your Hive's Sustainable Yield

- What is the principal idea in harvesting honey? A 3-Step Guide to a Responsible Harvest

- What is the most common method for cleaning a honey extractor? Protect Your Honey & Equipment

- How do you manually extract honey? Choose the Best Method for Your Hive

- How much honey does a beekeeper extract from the hive? A Guide to Sustainable Harvesting