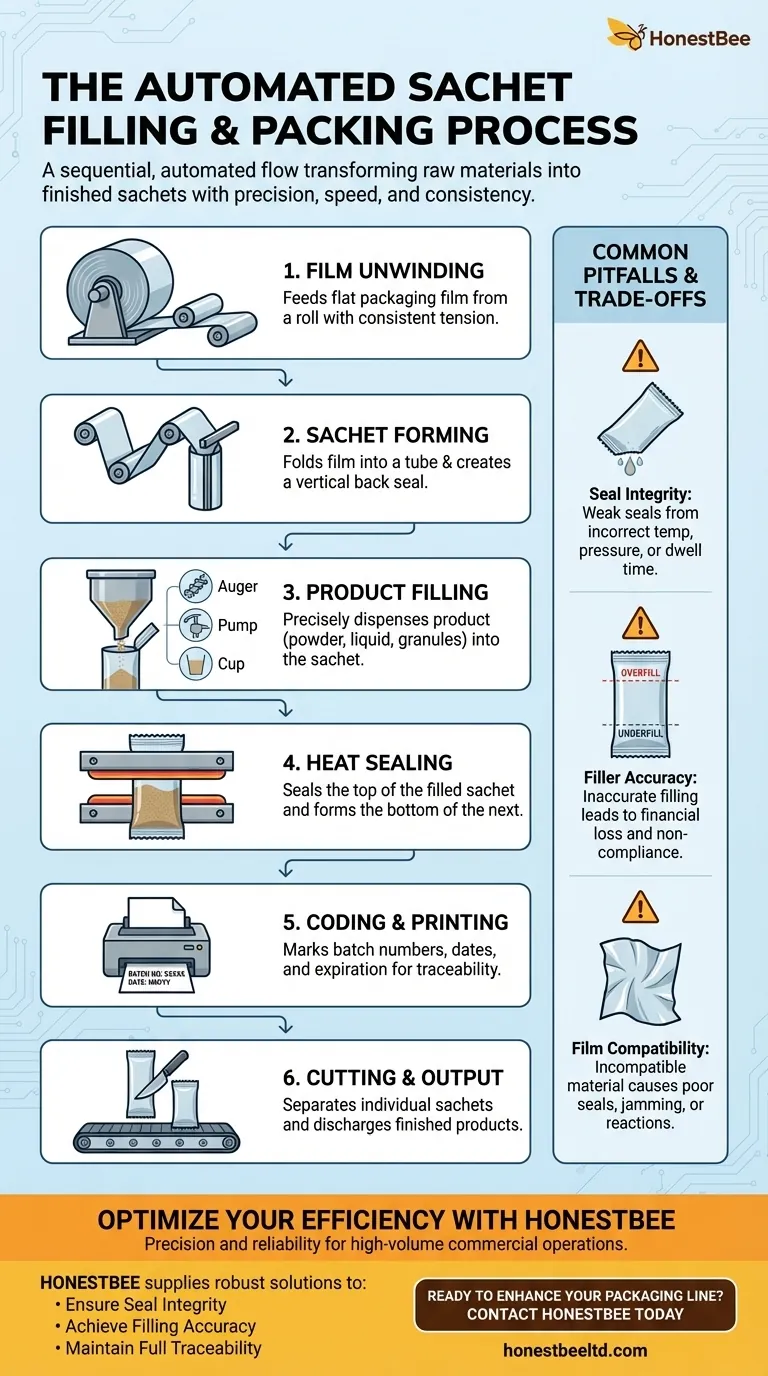

The primary operation of a sachet filling and packing machine is a sequential, automated process that transforms raw materials into finished products. The core stages include unwinding the packaging film, forming the sachet, filling it with the product, sealing it, printing necessary information, and finally, cutting the individual sachets for output.

At its core, a sachet machine is a system of synchronized stations. Its purpose is not just to package a product, but to do so with precision, speed, and consistency, ensuring the final sachet protects the product and meets quality standards.

The Automated Workflow: From Film to Finished Sachet

Understanding the sachet packing process is to understand a sequence of highly coordinated mechanical and electrical actions. Each step builds upon the last, and a failure at any stage compromises the entire output.

Step 1: Film Unwinding

This is the starting point of the entire process. A large roll of flat packaging film is mounted onto a spindle.

As the machine operates, it pulls the film off this roll, a process known as unwinding. The system maintains consistent tension to ensure the film feeds smoothly and without wrinkles.

Step 2: Sachet Forming

The flat film is then guided over a specialized tool, often called a forming collar or plow. This device folds the film into the required pouch shape.

Simultaneously, a vertical sealing bar presses the two outer edges of the folded film together, creating the sachet's back seal and turning the flat sheet into a continuous tube.

Step 3: Product Feeding and Filling

With the bottom of the sachet sealed by a horizontal jaw (from the previous cycle), the open tube is ready for filling. An automated filling system dispenses a precise, pre-measured amount of product into the sachet.

The type of filler is critical and depends entirely on the product:

- Auger Fillers: For powders like spices or flour.

- Volumetric Pumps: For liquids and pastes like shampoo or ketchup.

- Volumetric Cups: For granules like sugar or salt.

Step 4: Sachet Heat Sealing

Once the sachet is filled, a pair of horizontal sealing jaws clamps down. These heated bars perform two tasks at once.

They press together and heat-seal the top of the filled sachet while simultaneously forming the bottom seal of the next sachet in the continuous tube. This is a critical step for ensuring product integrity and shelf life.

Step 5: Coding and Printing

While clamped in the sealing jaws or immediately after, the sachet passes through a coding or printing station.

This system, which could be an embosser, inkjet, or thermal transfer printer, marks each sachet with essential information like the batch number, manufacturing date, and expiration date for traceability.

Step 6: Cutting and Output

Finally, a cutting mechanism, typically a sharp blade integrated into the sealing jaws, separates the completed sachet from the continuous film tube.

The finished sachet is then discharged from the machine, often onto a conveyor belt for collection and secondary packaging.

Understanding the Trade-offs and Common Pitfalls

While the process seems straightforward, its success hinges on the precise calibration of several interdependent variables. Mismanagement at any stage can lead to significant issues.

Seal Integrity

This is the most common failure point. A weak or incomplete seal can be caused by incorrect temperature, pressure, or dwell time of the sealing jaws. Product dust or liquid contaminating the seal area can also prevent a proper bond, leading to leaks and spoilage.

Filler Accuracy

Inaccurate filling leads directly to financial loss. Under-filling can result in regulatory non-compliance and customer complaints, while over-filling wastes product and cuts into profit margins. The filling system must be meticulously calibrated for the specific density and flow characteristics of the product.

Film Compatibility

Not all packaging films are created equal. The material must be compatible with the machine's sealing technology and the product itself. Using the wrong film can lead to poor seals, jamming, or chemical reactions that compromise the product.

Making the Right Choice for Your Goal

The ideal sachet machine configuration depends entirely on your product and priorities.

- If your primary focus is product safety and shelf life: Your most critical components are the sealing jaws and the choice of a high-barrier packaging film.

- If your primary focus is profitability and cost control: The accuracy and reliability of the product filling system are paramount to preventing waste.

- If your primary focus is regulatory compliance: Invest in a robust, high-resolution printing system to ensure every sachet is clearly coded for full traceability.

By understanding this sequence of operations, you can better diagnose issues, select the right equipment, and optimize your entire packaging process.

Summary Table:

| Step | Process | Key Function |

|---|---|---|

| 1 | Film Unwinding | Feeds flat packaging film from a roll with consistent tension. |

| 2 | Sachet Forming | Folds film into a tube and creates a vertical back seal. |

| 3 | Product Filling | Precisely dispenses product (powder, liquid, granules) into the sachet. |

| 4 | Heat Sealing | Seals the top of the filled sachet and forms the bottom of the next. |

| 5 | Coding/Printing | Marks batch numbers, dates, and expiration for traceability. |

| 6 | Cutting & Output | Separates individual sachets and discharges finished products. |

Optimize your sachet packaging efficiency with HONESTBEE.

For commercial apiaries and beekeeping equipment distributors, precision and reliability are non-negotiable. Whether you're packaging honey powders, supplements, or sanitizing granules, the right sachet machine ensures product integrity, minimizes waste, and maximizes throughput.

HONESTBEE supplies robust, wholesale-focused sachet filling and packing solutions designed for high-volume operations. We provide the equipment and expertise to help you:

- Ensure Seal Integrity: Protect your products from moisture and contamination.

- Achieve Filling Accuracy: Eliminate costly overfilling or compliance issues from underfilling.

- Maintain Full Traceability: Meet regulatory standards with clear, consistent coding.

Ready to enhance your packaging line? Contact HONESTBEE today to discuss your specific needs and discover how our equipment can drive your profitability.

Visual Guide

Related Products

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

People Also Ask

- How do automated honey filling and packaging machines affect profitability? Boost Margins with HONESTBEE Technology

- What is a Multi Lane Honey Sachet Packing Machine and when is it used? Maximize Your High-Volume Honey Production

- How do industrial honey filling machines assist producers in remaining competitive? Beat Imports with Precision

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- How are honey stick packs formed from the cut film strips? Master the Precision of Forming Tube Technology

- How do automatic honey filling and packaging lines enhance traceability? Secure Your Honey Supply Chain Integrity

- What is a fully-automatic honey filler? Streamline Your Production with High-Precision Automation

- How does automated honey filling and packaging equipment impact the value chain? Scale Your Global Honey Enterprise