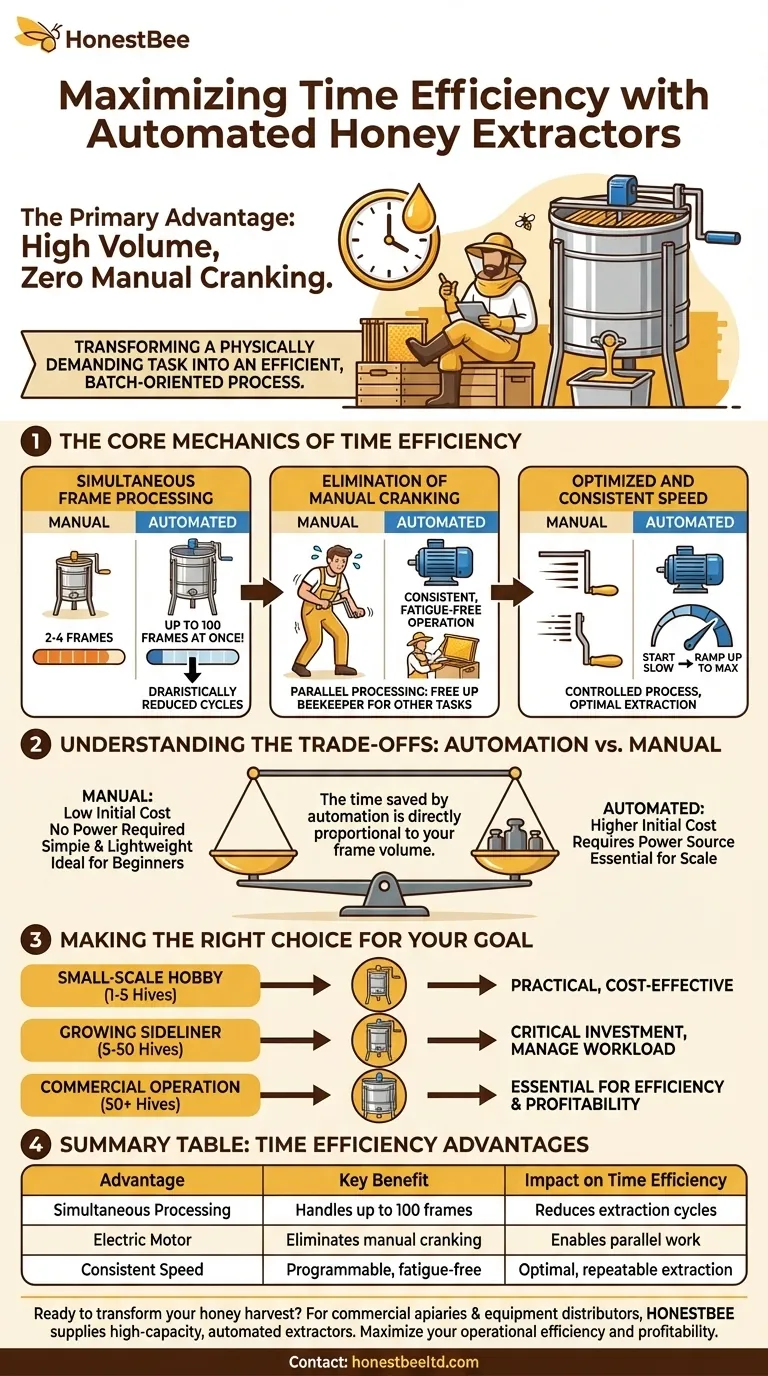

The primary time-saving advantage of an automated honey extractor is its ability to process a high volume of frames simultaneously and eliminate the physical labor of manual cranking. This transforms honey extraction from a physically demanding, frame-by-frame task into a far more efficient, batch-oriented process well-suited for larger beekeeping operations.

The decision between an automated and a manual honey extractor is not just about speed, but about scale. The time saved by automation must be weighed against its higher cost and power requirements, making the choice dependent on the size of your apiary and your production goals.

The Core Mechanics of Time Efficiency

Automated, or electric, extractors fundamentally change the workflow of a honey harvest. Their efficiency gains come from two key operational principles.

Simultaneous Frame Processing

Manual extractors typically hold a small number of frames, often between two and four. An automated extractor, by contrast, can have a capacity of up to 100 frames at once.

This ability to process in large batches is the single greatest source of time savings. It drastically reduces the number of cycles required to extract honey from an entire harvest.

Elimination of Manual Cranking

The second major advantage is the replacement of human labor with a consistent electric motor. Manual cranking is physically taxing and time-consuming.

An automated system runs continuously without fatigue, freeing the beekeeper to perform other critical tasks, such as uncapping the next batch of frames. This parallel processing multiplies overall efficiency.

Optimized and Consistent Speed

Many electric extractors offer variable speed controls. This allows for a more controlled and effective process, starting slow to prevent comb blowouts and then ramping up to maximum speed for full extraction.

A motor provides a level of consistency that is difficult to replicate by hand, ensuring each batch is processed optimally.

Understanding the Trade-offs: Automation vs. Manual

While faster, an automated extractor is not the default best choice for every beekeeper. Understanding the downsides is crucial for making an informed decision.

The Cost of Speed

The most significant drawback of an automated extractor is its higher initial cost. The investment can be substantial compared to a simple, affordable manual unit.

The Power Requirement

Automated extractors require a reliable source of electricity. This can be a major constraint for beekeepers operating in remote locations or off-grid apiaries where power is unavailable.

The Simplicity of Manual

Manual extractors are mechanically simple, lightweight, and easy to maintain. They are an excellent, cost-effective solution for beginners or those with only a few hives, where the time commitment for extraction is minimal.

The Labor Equation

The time saved by an automated extractor is directly proportional to the number of frames you need to process. For a small hobbyist, the time spent manually cranking a few frames is negligible. For a commercial beekeeper, it represents an insurmountable bottleneck.

Making the Right Choice for Your Goal

Selecting the right equipment comes down to aligning the tool with the scale of your operation.

- If your primary focus is a small-scale hobby (1-5 hives): A manual extractor is the most practical and cost-effective choice, as the time saved by automation does not justify the expense.

- If your primary focus is a growing sideliner business (5-50 hives): An automated extractor becomes a critical investment to manage the increasing workload and free up valuable time.

- If your primary focus is a commercial operation (50+ hives): A high-capacity automated extractor is an essential piece of equipment for maintaining operational efficiency and profitability.

Ultimately, the right extractor empowers you to manage your harvest effectively, turning a labor-intensive task into a manageable process.

Summary Table:

| Advantage | Key Benefit | Impact on Time Efficiency |

|---|---|---|

| Simultaneous Processing | Handles up to 100 frames at once | Drastically reduces the number of extraction cycles needed |

| Electric Motor | Eliminates manual cranking | Frees up the beekeeper for other tasks, enabling parallel work |

| Consistent Speed | Programmable, fatigue-free operation | Ensures optimal, repeatable extraction for every batch |

Ready to transform your honey harvest? For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies high-capacity, automated honey extractors designed to maximize your operational efficiency and profitability. Let our wholesale-focused expertise help you scale your production. Contact our team today to find the perfect extraction solution for your business.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- Why are Honey Extractor chambers 1.5mm aluminum or galvanized steel? Balance Food Safety and Durability

- What are the different types of honey extractor machines? Choose the Right Equipment for Your Apiary

- Why is cleaning a honey extractor important in beekeeping? Protect Your Honey Quality & Equipment

- What factors should beekeepers consider when choosing an extractor? Optimize Your Honey Harvest Efficiency

- What are the advantages of a radial honey extraction process? Double Your Efficiency and Reduce Labor Intensity

- How do hand-cranked cast iron centrifugal extractors function? Enhance Honey Purity & Hive Efficiency

- How is honey removed from the uncapped frames? Use Centrifugal Force for Maximum Efficiency

- How does the use of specialized honey extraction equipment influence Small Hive Beetle risk? Protect Your Apiary