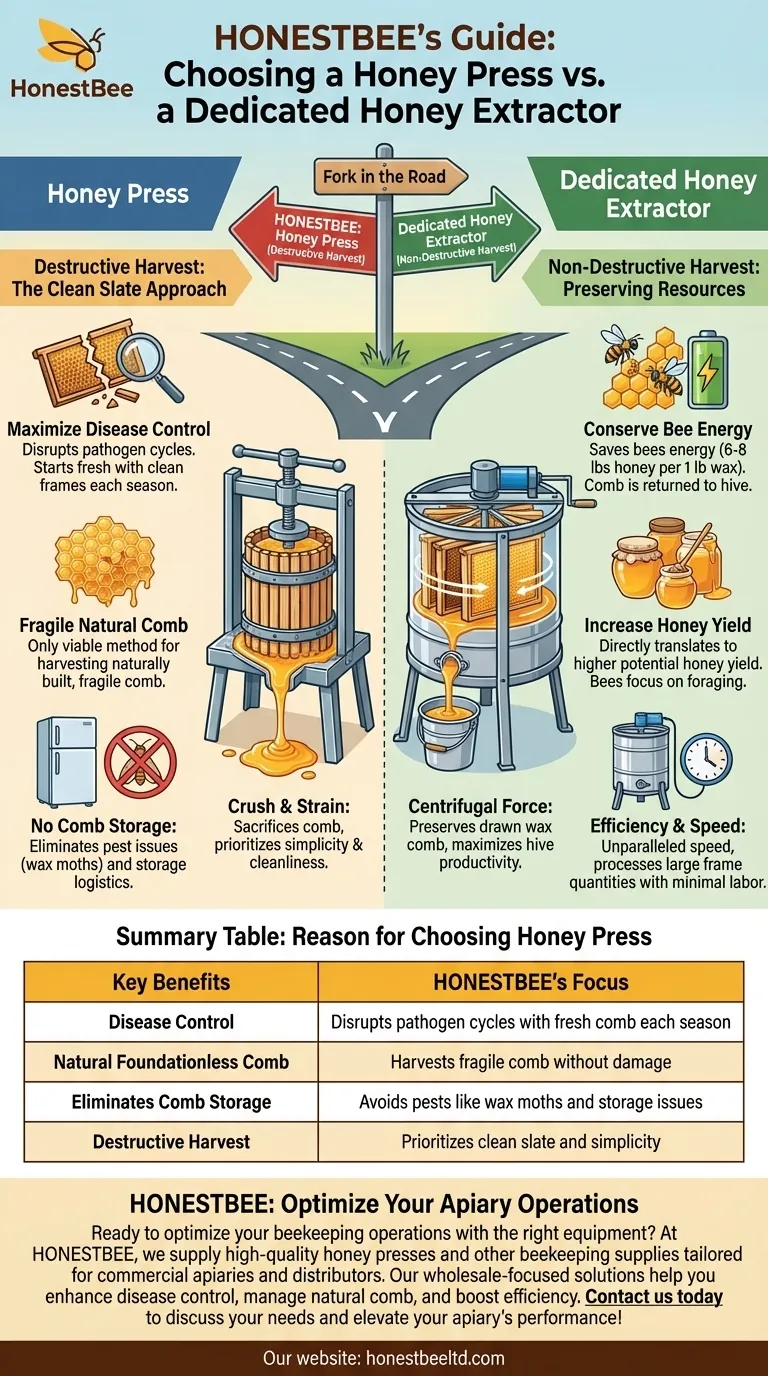

A honey press is chosen over an extractor for specific beekeeping practices where the comb is not intended to be reused. This choice is primarily driven by a desire for enhanced disease control, the use of natural foundationless comb that is too fragile for extraction, or the logistical challenge of storing empty frames.

The decision between a press and an extractor is not just about equipment; it reflects a fundamental choice between a destructive harvest (crush and strain) that prioritizes a clean slate each season and a non-destructive harvest (centrifugal extraction) that prioritizes the reuse of comb to save bee energy.

The Principle of a Destructive Harvest

Choosing a honey press means you are intentionally sacrificing the honeycomb. This "crush and strain" method is central to certain natural beekeeping philosophies that see benefits in forcing bees to build fresh comb each year.

Maximizing Disease Control

By using new frames with fresh wax starter strips each season, the beekeeper disrupts the potential life cycle of diseases and pathogens that can linger in old comb.

A press facilitates this approach because it makes salvaging the comb impossible, ensuring the beekeeper starts with a clean, disease-free foundation for the next honey flow.

Working with Natural, Foundationless Comb

Many beekeepers prefer to let bees build their own comb without the guide of foundation or reinforcing wires. This is often called foundationless beekeeping.

This naturally built comb is incredibly fragile and will disintegrate under the intense rotational force of a centrifugal honey extractor. A press is the only viable method for harvesting honey from these delicate frames.

Eliminating Comb Storage and Pests

Drawn comb that has been extracted must be stored properly. It is highly susceptible to pests, particularly the wax moth, whose larvae can decimate stored frames.

Proper storage often requires significant freezer space to kill pests or the use of chemical treatments. Using a press and melting the wax down eliminates this entire storage and pest management problem.

The Case for Centrifugal Extraction

While a press suits a specific methodology, the honey extractor remains the standard for most hobbyist and commercial beekeepers because it preserves the most valuable resource in the hive besides the bees themselves: the drawn wax comb.

Conserving Bee Energy

Bees expend an enormous amount of energy to produce wax and draw it out into honeycomb. It is estimated that bees consume 6-8 pounds of honey to produce just one pound of wax.

By returning empty drawn comb to the hive after extraction, beekeepers allow the colony to immediately begin refilling it with honey, bypassing the energy-intensive comb-building process.

Increasing Honey Yield

The energy saved by reusing comb translates directly into a higher potential honey yield. The bee workforce can focus exclusively on foraging for nectar and making honey rather than rebuilding their pantry from scratch.

Efficiency and Speed

For any beekeeper with more than a couple of hives, an extractor offers unparalleled speed and efficiency. Electric models, in particular, can process a large number of frames with minimal labor and without damaging the comb.

Understanding the Trade-offs

Neither method is universally superior; the correct choice depends entirely on your beekeeping goals and philosophy.

Press: Simplicity vs. Bee Labor

A press is a mechanically simple, often less expensive tool. However, the cost is transferred to your bees, which must constantly rebuild comb, potentially reducing your total honey harvest.

Extractor: Investment vs. Hive Productivity

An extractor is a significant upfront investment and creates the secondary challenge of storing the empty comb. However, it boosts the hive's overall productivity by preserving the bees' most energy-intensive work.

Making the Right Choice for Your Apiary

Your management style and goals for your hives are the most important factors in this decision.

- If your primary focus is natural beekeeping with foundationless frames: A honey press is your only practical option for harvesting.

- If your primary focus is maximizing honey yield with minimal hive disruption: An extractor is the clear choice for preserving comb and boosting productivity.

- If your primary focus is absolute disease prevention and breaking pest cycles: A press enables a system where you can start with entirely new frames each year.

Ultimately, understanding your beekeeping philosophy is the key to choosing the right tool for the job.

Summary Table:

| Reason for Choosing Honey Press | Key Benefits |

|---|---|

| Disease Control | Disrupts pathogen cycles with fresh comb each season |

| Natural Foundationless Comb | Harvests fragile comb without damage |

| Eliminates Comb Storage | Avoids pests like wax moths and storage issues |

| Destructive Harvest | Prioritizes clean slate and simplicity |

Ready to optimize your beekeeping operations with the right equipment? At HONESTBEE, we supply high-quality honey presses and other beekeeping supplies tailored for commercial apiaries and distributors. Our wholesale-focused solutions help you enhance disease control, manage natural comb, and boost efficiency. Contact us today to discuss your needs and elevate your apiary's performance!

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- In what specific beekeeping scenarios is a honey press utilized? Master the Crush and Strain Extraction Method

- What are the main benefits of using a honey-wax separating screw press? Boost Yield and Efficiency for Your Apiary

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods

- What role does pollen play in the quality of pressed honey? The Secret to a Creamy, Spreadable Texture

- What other functions can a honey press serve besides honey extraction? Discover Versatile Multi-Purpose Uses

- What is the recommended temperature for heating honey in a press? Preserve Quality & Maximize Yield

- How should the leftover wax cake from a honey press be handled and removed? Expert Tips for Clean Maintenance

- How can the use of specialized beekeeping hardware like propolis grids and wax presses improve production? Scale Now