To process bee products correctly and safely, the single most important requirement is that the work is done in a bee-proof space. This means the room must be fully sealed from the outside, with all potential entry points like windows, doors, and vents covered with a fine wire mesh to prevent bees from getting in.

A bee-proof space is not just about keeping a few bees out; it's the foundation of a safe and sanitary operation. It prevents widespread contamination and stops a dangerous "robbing" frenzy among bee colonies, which can devastate your hives.

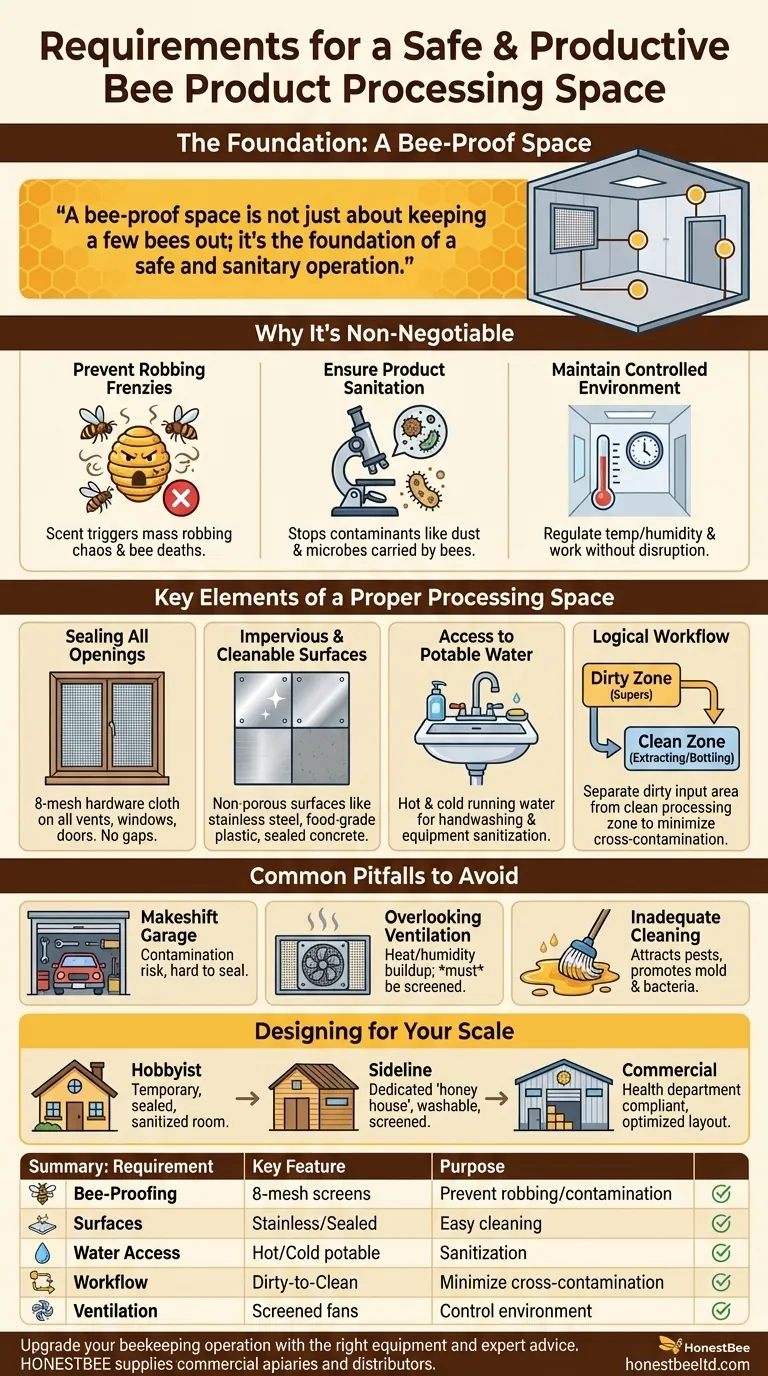

Why a Bee-Proof Space is Non-Negotiable

Understanding the "why" behind this rule is critical for any beekeeper. The requirement is based on two fundamental principles: bee behavior and food safety.

Preventing "Robbing Frenzies"

Bees are driven by scent. The powerful aroma of exposed honey during extraction can be detected by bees from other hives up to several miles away.

This triggers a behavior known as robbing, where thousands of bees from neighboring colonies will swarm your processing area in an attempt to steal the honey. This creates chaos, results in mass bee deaths, and can lead to your own colonies being attacked and depleted.

Ensuring Product Sanitation

Bees are insects that travel outdoors. They can carry dust, dirt, and microorganisms on their bodies.

Allowing bees into the processing area directly compromises the hygienic quality of your honey, wax, and other products. A sealed room is a basic requirement for producing a food-safe product free from external contaminants.

Maintaining a Controlled Environment

A well-sealed room gives you control over the processing environment. You can manage temperature and humidity, which is important for honey viscosity during extraction.

Most importantly, it ensures you can work without the constant stress and disruption of dealing with bees attracted to the honey.

Key Elements of a Proper Processing Space

A truly effective space goes beyond simply screening a window. It should be designed with the principles of a food-grade facility in mind, regardless of its size.

Sealing All Openings

This is the primary bee-proofing step. Every window, vent, and door must be secured. Use 8-mesh hardware cloth (8 squares per linear inch) or a finer screen, ensuring there are no gaps around the edges. A double-door or entryway vestibule is an excellent feature for commercial-grade spaces.

Impervious and Cleanable Surfaces

The ideal processing room has surfaces that are non-porous and easy to clean and sanitize.

Materials like stainless steel, food-grade plastics, and sealed concrete floors are ideal. Avoid exposed or unsealed wood, as it can absorb honey and moisture, making it impossible to truly clean and promoting bacterial growth.

Access to Potable Water

Your processing space must have convenient access to both hot and cold running water. This is essential for washing hands, cleaning spills, and sanitizing your extracting equipment, tanks, and containers. A dedicated hand-washing station is a critical component of food safety.

Logical Workflow

Arrange your space to create a logical flow from "dirty" to "clean." The area where you bring in honey supers from the apiary should be separate from the "clean" zone where extracting, filtering, and bottling takes place. This minimizes the risk of cross-contamination.

Common Pitfalls to Avoid

Setting up a space correctly means avoiding common mistakes that can compromise your product and your bees.

The Makeshift Garage Problem

Many hobbyists start by extracting in a garage. While convenient, this poses risks. Garages often house chemicals, gasoline, and dust that can contaminate your honey. They are also notoriously difficult to completely seal from pests and bees.

Overlooking Ventilation

A completely sealed room can become incredibly hot and humid during extraction. You must plan for ventilation. This can be an exhaust fan or windows that can be opened, but they must be securely screened to maintain the bee-proof barrier.

Inadequate Cleaning Protocols

The physical space is only half the battle. You must have a strict cleaning protocol. Spilled honey should be cleaned up immediately. At the end of a processing session, all equipment and surfaces must be thoroughly washed and sanitized to prevent mold and to stop attracting pests.

Designing Your Space for Your Scale

The right approach depends on the size of your operation. Your goal is to meet the principles of safety and sanitation within your budget and scale.

- If you are a small-scale hobbyist: Focus on temporarily converting a single room, like a clean utility room or kitchen. Before starting, ensure it is completely sealed and that all food-preparation surfaces are sanitized.

- If you are scaling up to a sideline business: Invest in a dedicated space like a purpose-built "honey house" or a retrofitted shed. Prioritize washable surfaces, screened ventilation, and a layout that separates wet and dry activities.

- If you are running a commercial operation: You must design a facility that complies with your local health department's food processing regulations, which will include requirements for materials, plumbing, and workflow.

A well-designed processing space is an investment that protects your bees, your product, and your reputation.

Summary Table:

| Requirement | Key Feature | Purpose |

|---|---|---|

| Bee-Proofing | 8-mesh screens on all openings | Prevent robbing frenzies & contamination |

| Surfaces | Stainless steel, sealed concrete | Easy cleaning & sanitation |

| Water Access | Hot/cold potable water supply | Hand washing & equipment sanitization |

| Workflow | Logical 'dirty-to-clean' zones | Minimize cross-contamination |

| Ventilation | Screened exhaust fans/windows | Control temperature & humidity |

Upgrade your beekeeping operation with the right equipment and expert advice. HONESTBEE supplies commercial apiaries and distributors with wholesale-focused beekeeping supplies and equipment designed for safe, efficient processing. Let us help you build a compliant, productive honey house. Contact our team today for a consultation!

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

People Also Ask

- Why is a centrifugal honey extractor considered core equipment? Boost Your API's Efficiency and Yield

- What are the main benefits of using a honey extractor? Maximize Yields and Protect Your Honeycomb

- Why is high-efficiency commercial honey harvesting equipment required for high-yield forests? Maximize Your Annual Yield

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation

- What role does specialized honey extraction equipment play in the post-harvest honey processing stage? Boost Yield & Quality