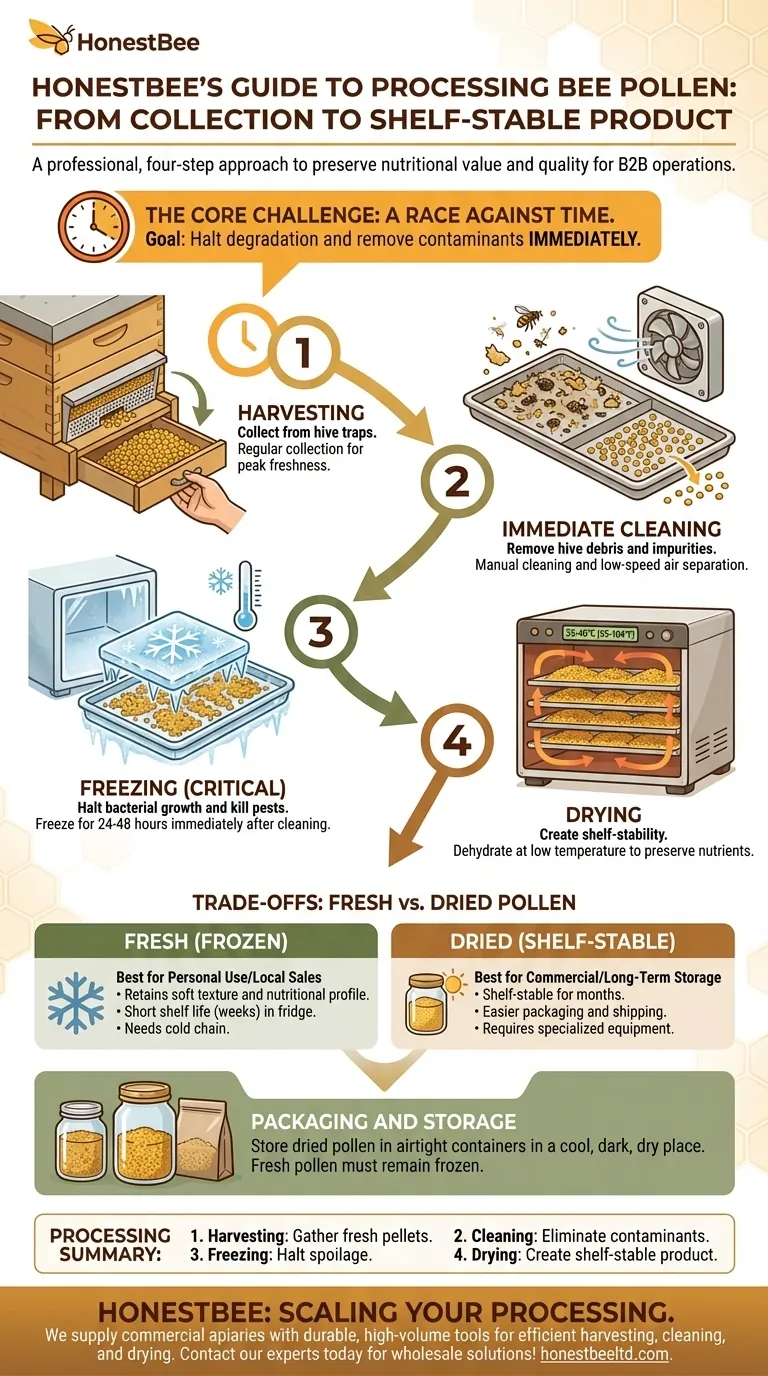

To properly process bee pollen, you must follow a sequence of harvesting, cleaning, immediate freezing, and then either drying for long-term storage or packaging for immediate sale. Each step is essential for preserving the pollen's nutritional value and preventing spoilage, as it is a highly perishable product.

The core challenge in processing bee pollen is a race against time. Your primary goal is to immediately halt natural degradation and remove contaminants to lock in the pollen's quality and ensure its safety for consumption.

The Four Critical Stages of Pollen Processing

Successfully preparing bee pollen for storage or sale involves a methodical, four-step process. Skipping or rushing any of these stages can compromise the final product's quality, safety, and shelf life.

Step 1: Harvesting from the Trap

This is the starting point of the entire process. Pollen is collected from traps fitted to the hive entrance, which gently scrape the pollen pellets from the bees' legs as they enter.

Regular collection is key to ensuring the pollen you harvest is as fresh as possible.

Step 2: Immediate and Thorough Cleaning

Freshly harvested pollen will contain various hive debris, including bee parts, wax, and other impurities. This material must be removed immediately to prevent contamination.

A preliminary manual cleaning can remove larger debris. For finer particles, a low-speed fan can be used to gently blow away lighter contaminants from the heavier pollen pellets after they are dried.

Step 3: Freezing for Initial Preservation

Fresh pollen spoils very quickly due to its moisture content. Freezing is the most critical step to halt bacterial growth and preserve freshness right after cleaning.

Spread the cleaned pollen in a thin layer on a tray to keep the pellets separate and freeze them for at least 24 to 48 hours. This not only preserves the pollen but also helps kill any potential pests or their eggs.

Step 4: Drying for Long-Term Storage

While freezing is excellent for short-term preservation, drying is necessary for creating a shelf-stable product. This step removes the moisture that leads to mold and spoilage.

Use a food dehydrator or an oven with a very low setting, maintaining a temperature between 35-40°C (95-104°F). Higher temperatures can destroy the pollen's delicate nutrients.

Understanding the Trade-offs: Fresh vs. Dried Pollen

The decision to keep pollen frozen or proceed with drying depends entirely on your storage needs and how you intend to use or sell it.

The Case for Fresh (Frozen) Pollen

Keeping pollen frozen after the initial cleaning is the best way to maintain its "fresh" state. The texture remains softer and many believe the nutritional profile is best preserved this way.

This method is ideal for personal use or for selling directly to local customers who can keep it frozen. It can be moved to a refrigerator, but its shelf life there is short—no more than a couple of weeks before mold becomes a risk.

The Case for Dried Pollen

Drying is the standard for commercial operations or anyone needing long-term storage. Properly dried pollen is shelf-stable for many months, making it far easier to package, ship, and sell.

The key trade-off is the need for specialized equipment (a dehydrator) and careful temperature control. However, this effort results in a durable product that is not dependent on a "cold chain" for distribution.

Final Steps: Packaging and Storage

How you store your processed pollen is just as important as the processing itself. Improper storage can undo all your careful work.

Storing Dried Pollen

Once dried and completely cooled, pollen must be stored in airtight containers. This prevents moisture from re-entering and causing spoilage.

Keep these containers in a cool, dark, and dry place. Exposure to light, heat, or humidity will degrade the quality of the pollen over time.

Storing Fresh Pollen

If you choose not to dry the pollen, it must remain frozen in airtight bags or containers. Only remove what you intend to use or sell in the immediate future.

Making the Right Choice for Your Goal

Your approach to processing should align directly with your end goal for the pollen.

- If your primary focus is personal use or quick local sales: Cleaning and then freezing the pollen is the best method to preserve maximum freshness for short-term consumption.

- If your primary focus is long-term storage or commercial distribution: A complete process of cleaning, freezing, and careful drying is the only way to create a safe, shelf-stable product.

Mastering these processing steps ensures the quality, safety, and value of every pollen pellet you harvest.

Summary Table:

| Processing Step | Key Action | Primary Goal |

|---|---|---|

| 1. Harvesting | Collect from pollen traps on hives. | Gather fresh pollen pellets. |

| 2. Cleaning | Remove hive debris (bee parts, wax). | Eliminate contaminants for safety. |

| 3. Freezing | Freeze for 24-48 hours immediately after cleaning. | Halt spoilage and kill pests. |

| 4. Drying | Dehydrate at 35-40°C (95-104°F). | Create a shelf-stable product for storage. |

Ready to scale your bee pollen processing with professional-grade equipment?

As HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, high-volume tools needed for efficient harvesting, cleaning, and drying. Our wholesale-focused operations ensure you get reliable equipment that preserves the quality and value of your product.

Contact our experts today to discuss your commercial pollen processing needs!

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Plastic Chinese Queen Grafting Tool for Bee Queen Rearing

- Lightweight Durable Plastic Queen Excluder Scraper for Beekeeping

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

People Also Ask

- Why is a temperature-controlled logistics system required for fresh bee pollen? Preserve Chemical Accuracy & Data

- What percentage of pollen pellets can a typical pollen trap collect? Optimize Your Harvest & Hive Health

- What are the design principles of an effective pollen trap? Master Sustainable Harvesting for Commercial Success

- What role does ultrasonic extraction equipment play in bee pollen processing? Unlock High-Purity Bioactive Yields

- When should pollen trapping be considered? A Guide for Responsible Beekeepers

- What role does industrial deep-freezing equipment play in the long-term preservation of fresh pollen supplemental feed?

- What is the importance of using professional sample collection consumables for honey and pollen pesticide monitoring?

- How does high-concentration honey reduce bee pollen fungal load? Master Natural Sterilization Techniques