At its core, processing comb honey into liquid honey involves two primary methods suitable for small-scale operations: the crush and strain method and the pressing method. The crush and strain technique is the most accessible, requiring only basic kitchen equipment to break up the wax comb and filter the honey out. The pressing method uses mechanical force to squeeze the honey from the comb, which can be more efficient but requires specialized or DIY equipment.

The fundamental challenge is not just extracting honey, but separating it cleanly from the wax. While a centrifugal extractor is the standard for large operations, the crush and strain method offers a simple, effective starting point for any hobbyist.

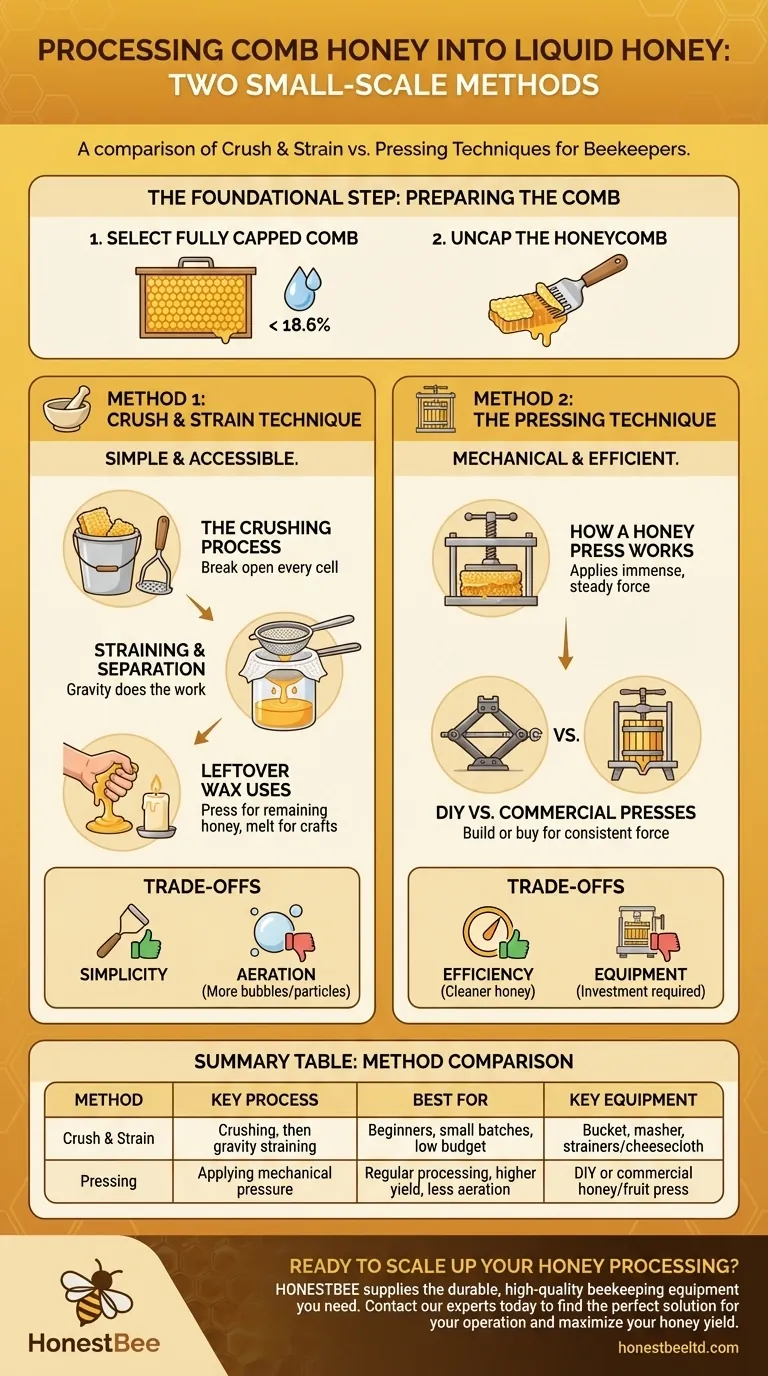

The Foundational Step: Preparing the Comb

Before you can extract any honey, the comb must be properly prepared. Skipping this step will compromise the quality and success of your extraction.

Select Fully Capped Comb

First, ensure your honey is ready for harvest. The bees will seal a cell of honey with a wax cap only when the honey has been dehydrated to the correct moisture content (under 18.6%). Using uncapped or partially capped comb risks harvesting "green" honey that can ferment and spoil.

Uncap the Honeycomb

The wax caps create a perfect seal that must be broken. Using a serrated uncapping knife or a specialized uncapping fork, you must slice or scratch open the tops of the honeycomb cells. This allows the liquid honey to flow out during extraction.

Method 1: The Crush and Strain Technique

This is the most straightforward and common method for hobbyists due to its simplicity and minimal equipment requirements.

The Crushing Process

Place your uncapped comb into a clean, food-grade bucket. Use a simple tool like a potato masher or even just your clean hands to crush the comb thoroughly. The goal is to break open every cell to release the honey.

Straining and Separation

Pour the mixture of honey and crushed wax through a strainer system. A double sieve, with a coarse mesh on top to catch large wax pieces and a fine mesh below, works well. For even clearer honey, you can line the fine sieve with cheesecloth. Allow gravity to do the work, letting the honey drip into a clean container below.

What to Do with the Leftover Wax

The wax left in the strainer will still contain a surprising amount of honey. You can squeeze this wax by hand (inside the cheesecloth) to press out the remaining honey. The resulting wax can then be washed and melted down for use in candles, balms, or other crafts.

Method 2: The Pressing Technique

Pressing is a more mechanical approach that squeezes honey from the comb rather than just letting it drain. It can yield more honey with less aeration.

How a Honey Press Works

A press applies immense, steady pressure to a mass of crushed honeycomb. This force efficiently squeezes the liquid honey out, leaving behind a compressed cake of wax.

DIY vs. Commercial Presses

You can build a simple press using two sturdy wooden boards and a car jack to apply pressure. For more regular use, beekeepers can purchase dedicated fruit or honey presses, which typically use a screw mechanism to apply force more evenly.

Understanding the Trade-offs

Neither method is perfect; each comes with clear advantages and disadvantages that will influence your choice.

Crush and Strain: Simplicity vs. Aeration

This method's primary benefit is its simplicity. You likely already own the necessary tools. However, the crushing and pouring process can introduce more air bubbles and fine wax particles into the honey, requiring more time for it to settle and clarify.

Pressing: Efficiency vs. Equipment

A press is generally more efficient at extracting the maximum amount of honey from the wax. The resulting honey is often cleaner from the start. The clear downside is the need for the press itself, which represents an investment of either time (to build a DIY version) or money (to buy a commercial one).

What About Centrifugal Extractors?

It is important to know that most commercial beekeepers use a centrifugal extractor. This machine spins frames at high speed, flinging the honey out without destroying the comb. This allows the beekeeper to return the empty "drawn" comb to the hive, saving the bees significant energy. However, extractors are a major equipment investment and are generally unnecessary for small-scale comb honey processing.

Making the Right Choice for Your Goal

Your decision should be based on your scale, budget, and long-term beekeeping goals.

- If you are a beginner or processing a small amount: The crush and strain method is your best choice for its low cost and simplicity.

- If you plan to process honey regularly: Consider building or buying a small press to improve your yield and efficiency.

- If your goal is to scale up and preserve comb: A centrifugal extractor is the next logical step in your journey as a beekeeper.

Ultimately, both the crush and strain and pressing methods will successfully turn your beautiful honeycomb into delicious liquid honey.

Summary Table:

| Method | Key Process | Best For | Key Equipment |

|---|---|---|---|

| Crush & Strain | Crushing comb, then straining honey via gravity. | Beginners, small batches, low budget. | Bucket, masher, strainers/cheesecloth. |

| Pressing | Applying mechanical pressure to squeeze honey out. | Regular processing, higher yield, less aeration. | DIY or commercial honey/fruit press. |

Ready to scale up your honey processing? Whether you're a hobbyist looking for your first strainer or a commercial apiary sourcing a honey press, HONESTBEE supplies the durable, high-quality beekeeping equipment you need. Contact our experts today to find the perfect solution for your operation and maximize your honey yield.

Visual Guide

Related Products

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- How does centrifugation work in honey extraction? The Sustainable Method for Modern Beekeepers

- What is the frame capacity of manual honey extractors? The Ideal Choice for Small-Scale Beekeepers

- How long does it take to extract honey with a manual extractor? A Guide for Hobbyist Beekeepers

- What is a tangential extractor and how does it work? A Complete Guide for Hobbyist Beekeepers

- Is the honey extractor better than the honey press? Choose the Right Tool for Your Apiary's Success