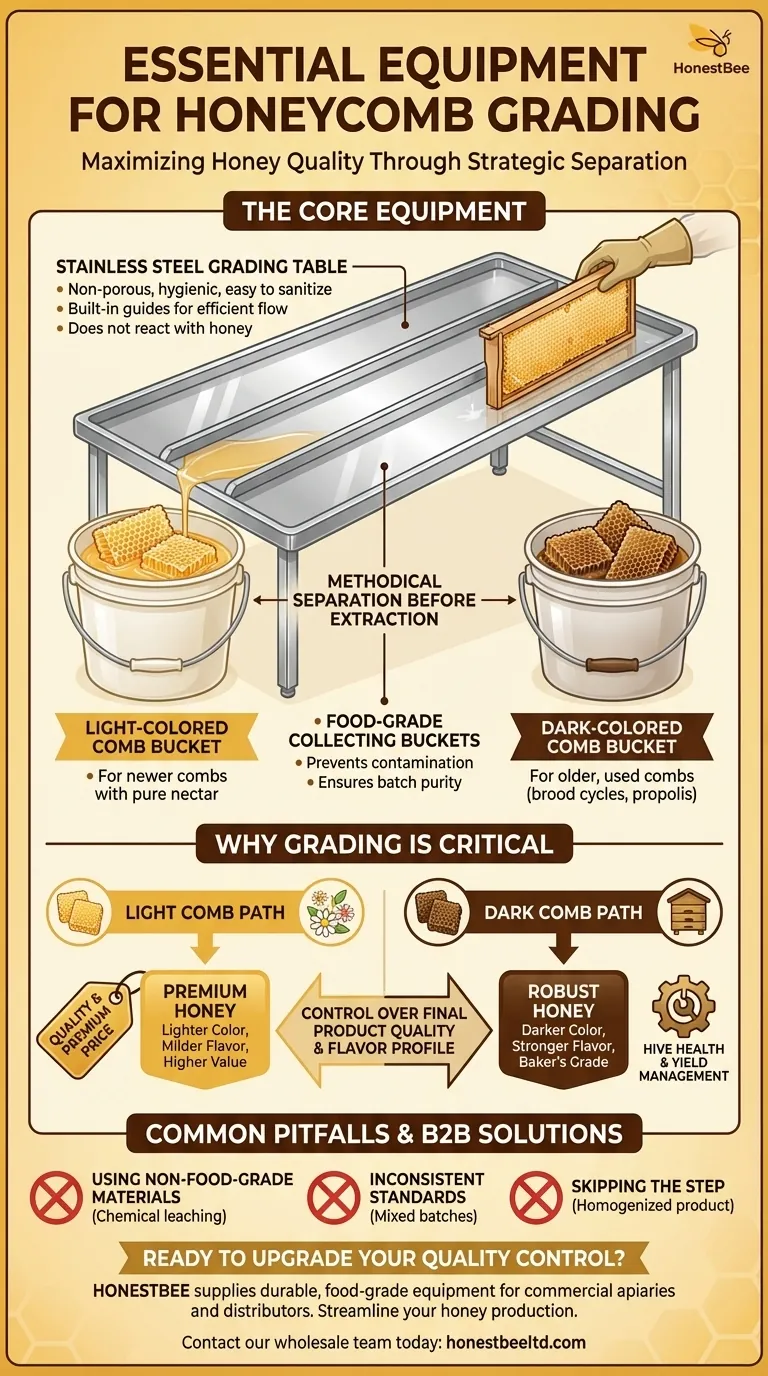

To properly grade honeycombs, the essential equipment is surprisingly simple: a specialized stainless steel grading table and dedicated collecting buckets. This setup is specifically designed to facilitate the crucial task of separating light-colored combs from dark-colored combs before honey extraction. This separation is the key to controlling the quality, color, and flavor of your final honey harvest.

The equipment for grading honeycombs is straightforward, but its purpose is profound. The goal is not just to own the tools, but to use them for methodical separation, which gives you direct control over the quality and characteristics of your honey.

The Core Equipment for Honeycomb Grading

The physical setup for grading is minimal and focused entirely on efficiency and hygiene. Every component has a specific function in the workflow.

The Stainless Steel Grading Table

The centerpiece of the operation is the grading table. It is almost always made of stainless steel because the material is non-porous, easy to sanitize, and will not react with the honey.

This table typically features guides or channels, sometimes referred to as "tow leads." These are built-in pathways that allow a beekeeper to quickly and cleanly slide a honeycomb frame to one end of the table or the other after inspection.

Dedicated Collecting Buckets

At each end of the table, a collecting bucket is placed. One bucket is designated for the light-colored combs, and the other is for the dark ones.

It is critical that these buckets are made of food-grade material to prevent any contamination of the honey. This simple two-bucket system is the endpoint of the grading process, ensuring the two types of comb remain separate before they move to the extractor.

Why Grading Honeycombs is a Critical Step

Understanding the equipment is only half the story. The real value comes from understanding why this separation is a cornerstone of quality honey production and good hive management.

Impact on Honey Quality

Lighter, newer combs typically contain purer nectar. Extracting honey from only these combs results in a lighter-colored, milder-flavored honey that often commands a premium price.

Darker combs are older and have been used for multiple brood cycles. They contain remnants of cocoons, more propolis, and a higher concentration of pollen, all of which lead to a darker, more robustly flavored honey. While some prefer this strong flavor, mixing it with light honey diminishes the quality of the premium batch.

The Grading Process in Action

The workflow is simple. A beekeeper takes a frame of capped honey, uncaps it, and then places it on the grading table. A quick visual inspection determines if it is predominantly light wax or dark wax.

Based on that judgment, the frame is slid down the appropriate channel into either the "light comb" bucket or the "dark comb" bucket, ready for extraction in separate batches.

Common Pitfalls to Avoid

While the process is simple, a few common mistakes can undermine the benefits of grading.

Using Non-Food-Grade Materials

Never use buckets or place your combs on surfaces that are not food-grade. Plastics not intended for food can leach chemicals, and other materials can harbor bacteria, contaminating your entire harvest.

Inconsistent Grading Standards

The purpose of grading is defeated if your criteria for "light" and "dark" change from frame to frame. Establish a consistent visual standard and stick to it to ensure your batches are genuinely distinct.

Skipping the Step Entirely

The most common mistake is to skip grading altogether for the sake of speed. Extracting all combs together creates a single, homogenized batch of honey. You lose the ability to produce a premium, light honey and have less control over the final product's flavor profile.

Grading for Your Specific Goal

How you apply this process depends on your ultimate objective as a beekeeper.

- If your primary focus is premium, light-colored honey: Be ruthless in your grading and only allow the very lightest combs into your premium batch.

- If your primary focus is maximizing yield: You can create a secondary, "baker's grade" honey from the darker combs, ensuring no harvest goes to waste.

- If your primary focus is hive health: Use the grading process as an opportunity to identify and cull the oldest, darkest combs to be melted down and replaced with fresh foundation.

Ultimately, grading your honeycombs is a simple practice that provides precise control over the final product you offer.

Summary Table:

| Essential Equipment | Key Features | Purpose |

|---|---|---|

| Stainless Steel Grading Table | Non-porous, easy to sanitize, built-in guides/tow leads | To visually inspect and separate light and dark honeycombs efficiently. |

| Food-Grade Collecting Buckets | Made of safe, non-contaminating materials (one for light combs, one for dark) | To keep the graded honeycombs separate before extraction, ensuring batch purity. |

Ready to upgrade your honey quality control?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, food-grade equipment needed for efficient honeycomb grading. Our stainless steel tables and buckets are designed for high-volume, hygienic operations.

Contact our wholesale team today to discuss your equipment needs and streamline your honey production.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Honeycomb Style Drip Free Honey Dispenser

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What steps should be followed when starting and stopping the vacuum pump in the honey vacuum thickener? Protect Your Honey & Equipment

- What additional functions does a honey vacuum thickener have? Achieve a Stable, Commercial-Grade Product

- What is the typical drying performance of the disc dehumidifier-concentrator for honey? Optimize Your Honey Processing

- What are the main components of the honey vacuum thickener equipment? A Guide to Preserving Honey Quality

- How is the cooling system configured when using tap water in the honey vacuum thickener? A Simple Guide for Beekeepers