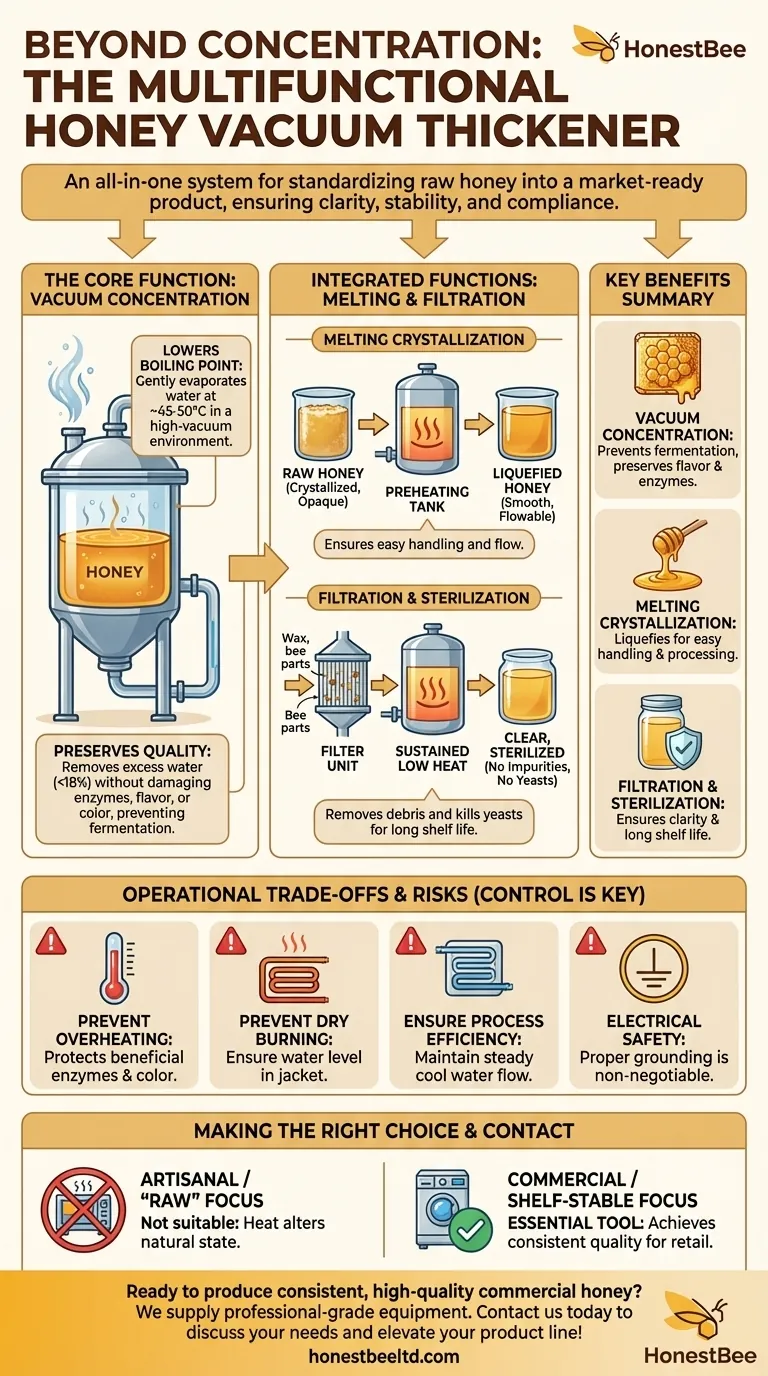

Beyond simple thickening, a honey vacuum thickener is a multi-functional processing unit designed to refine raw honey into a stable, market-ready product. In addition to its primary role of concentration, it also performs crucial melting and filtration functions, which are integral to improving honey quality and shelf life.

The true purpose of a honey vacuum thickener is not just to remove water, but to serve as an all-in-one system for standardizing honey. It ensures clarity, stability, and compliance with commercial standards by integrating heating, filtering, and concentration into a single, efficient process.

The Core Function: Vacuum Concentration

How It Lowers Water Content

A honey vacuum thickener operates on a simple principle of physics: the boiling point of water decreases as atmospheric pressure drops. The equipment creates a high-vacuum environment inside its concentration tank.

This allows the water in the honey to evaporate at a much lower temperature (around 45-50°C) than it would at normal atmospheric pressure.

Why Concentration is Critical

This gentle evaporation process is crucial for removing excess water without damaging the honey's delicate enzymes, flavor, and color. Reducing the water content to below 18% prevents fermentation, meets national and international standards, and ensures the honey can be preserved for a long time.

Beyond Concentration: The Integrated Functions

While concentration is the main event, the machine performs other vital tasks that prepare the honey for a commercial setting.

Melting Crystallization

Raw, unprocessed honey often contains sugar crystals, making it thick, opaque, and difficult to handle. The first stage in the thickener is a preheating tank.

This tank gently warms the honey to a controlled temperature, melting any existing crystals and returning the honey to a smooth, liquid state. This step is essential for ensuring the honey can flow easily through the rest of the system.

Filtration and Sterilization

After being liquefied in the preheating tank, the honey passes through a filter. This removes physical impurities such as wax particles, bee parts, and other debris that may be present after extraction.

The sustained low heat during both preheating and concentration also serves a secondary purpose: sterilization. It helps to kill naturally occurring yeasts that could otherwise cause the honey to ferment and spoil over time.

Understanding the Trade-offs and Operational Risks

While highly effective, operating a honey vacuum thickener requires careful attention to avoid compromising honey quality or creating safety hazards.

Risk of Damaging the Honey

The primary advantage of vacuum concentration is the use of low heat. However, improper temperature control or prolonged heating can still damage the honey. Overheating can destroy beneficial enzymes and darken the honey's color, reducing its market value.

Preventing Equipment Damage

The equipment's heating elements are susceptible to damage. You must ensure the water level in the jacket of both the preheating and concentration tanks is sufficient to prevent the heaters from dry burning.

Ensuring Process Efficiency

The efficiency of the entire process depends on the vacuum pump and the condenser. The condenser requires a steady flow of cool water to turn the evaporated water vapor back into a liquid. If the cooling water gets too warm, the condenser's efficiency drops, the vacuum weakens, and the concentration process will slow significantly.

Electrical Safety

As with any industrial equipment, proper grounding is non-negotiable. The machine's shell must be securely grounded to prevent the risk of electrical shock to the operator.

Making the Right Choice for Your Goal

The decision to use a honey vacuum thickener depends entirely on your final product goals.

- If your primary focus is producing artisanal, "raw" honey: This machine is likely not suitable, as any application of heat technically alters the honey from its most natural state.

- If your primary focus is creating a shelf-stable commercial product: This equipment is an essential tool for achieving consistent quality, clarity, and longevity required for retail.

Ultimately, a honey vacuum thickener empowers producers to transform raw honey into a consistent, stable, and high-quality product ready for a broader market.

Summary Table:

| Function | Key Benefit |

|---|---|

| Vacuum Concentration | Gently removes water to prevent fermentation, preserving flavor and enzymes. |

| Melting Crystallization | Liquefies honey for easy handling and processing. |

| Filtration & Sterilization | Removes debris and kills yeasts to ensure clarity and long shelf life. |

Ready to produce consistent, high-quality commercial honey?

At HONESTBEE, we supply professional-grade honey vacuum thickeners and beekeeping equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable machinery needed to standardize your honey, improve efficiency, and meet market demands.

Contact us today to discuss your honey processing needs and elevate your product line!

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- How do standardized post-harvesting processing machines ensure honey quality? Optimize Purity and Shelf Life

- Why is a high-precision digital conductivity meter required for honey EC testing? Ensure Honey Purity and Origin

- What is the role of specialized honey processing machinery? Unlock Market Compliance & Efficiency

- What is involved in honey processing? From Hive to Jar for Perfect Quality

- What is the role of a high-precision laboratory oven in honey moisture content analysis? Master Quality Control

- Why are honey and beeswax deep-processing machines important? Extend the Value Chain and Maximize Your Profits

- How do industrial honey processing and packaging machines enhance the market value? Scale Your Honey Export Potential

- What is the primary value of automated sterile processing and packaging systems? Elevate Your Honey Quality & Scale