At its core, a honey processing machine is an integrated system designed to refine raw honey by removing impurities and excess water content. Its primary features include a preheating tank, mechanical filters, and a low-temperature vacuum concentrator, all typically constructed from food-grade stainless steel to ensure product purity and operational durability.

The central purpose of a honey processing machine is to elevate both the quality and efficiency of honey production. It achieves this by using controlled, low-temperature processes to purify and stabilize honey, preserving its natural integrity while enabling significant increases in output.

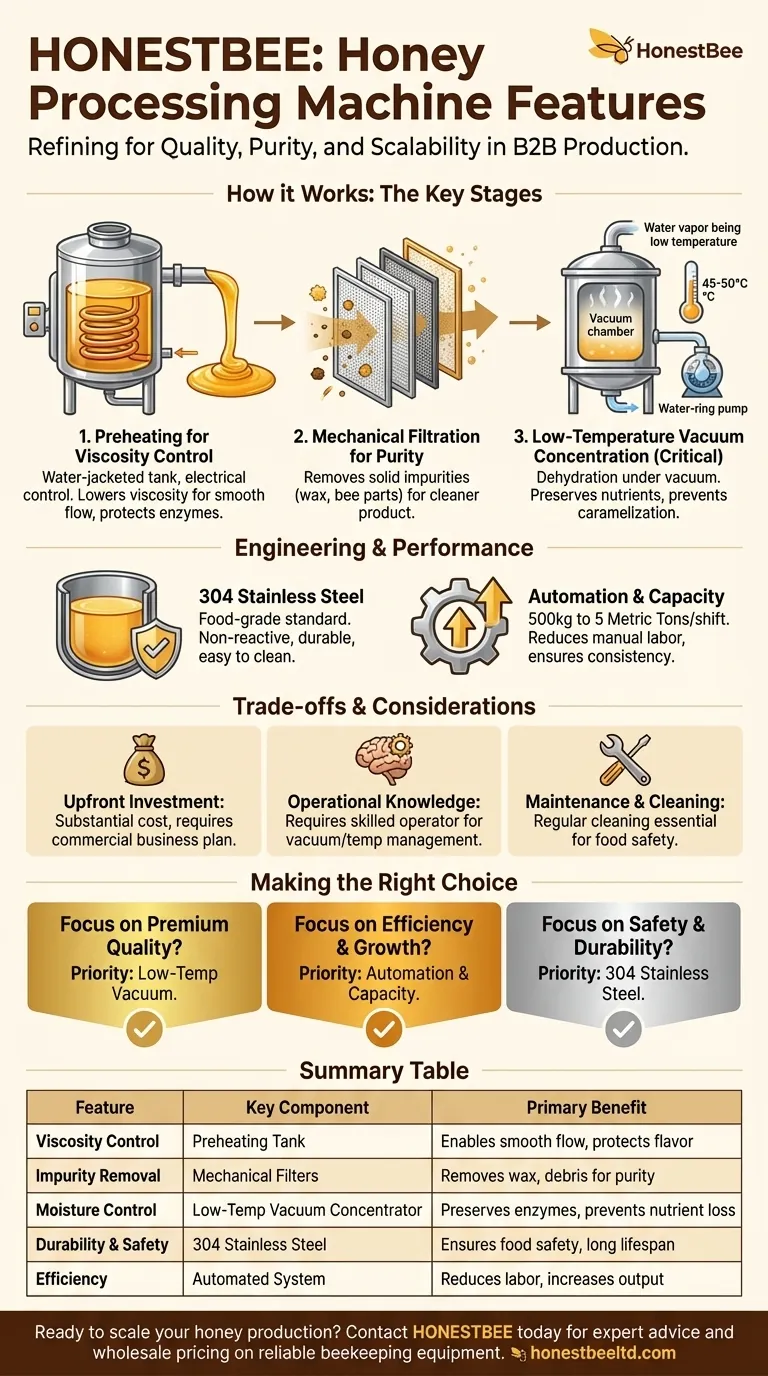

How a Honey Processing Machine Works: The Key Stages

A honey processing machine executes a series of steps, each designed to address a specific challenge in preparing honey for market. Understanding these stages reveals why each feature is critical.

Stage 1: Preheating for Viscosity Control

Raw honey is thick and viscous, making it difficult to pump and filter. The machine uses a water-jacketed preheating tank with electrical control to gently warm the honey.

This controlled heating lowers the honey's viscosity, allowing it to flow smoothly without reaching temperatures that would damage its delicate enzymes and flavors.

Stage 2: Mechanical Filtration for Purity

Once warmed, the honey passes through a series of mechanical filters. These filters are designed to physically remove solid impurities.

This stage is crucial for clearing the honey of debris such as wax particles, bee parts, and other hive material, resulting in a cleaner and more commercially appealing final product.

Stage 3: Low-Temperature Vacuum Concentration

The most critical stage for quality is dehydration. The machine uses a low-temperature vacuum concentration system, powered by a water-ring vacuum pump.

Creating a vacuum lowers the boiling point of water. This allows the machine to remove excess moisture from the honey (reducing water content to the ideal 18-20%) at a low temperature (around 45-50°C). This process prevents the caramelization and nutrient degradation associated with high-heat methods.

The Engineering Behind the Performance

The machine's effectiveness is not just in its process but also in its construction and capacity, which directly impact reliability and return on investment.

The Role of 304 Stainless Steel

These machines are built with double-thickened tanks made of 304 stainless steel. This material is the industry standard for food processing.

Its non-reactive surface ensures that the honey's taste and chemical composition are not altered. Furthermore, it is highly durable and easy to clean, which is essential for maintaining food safety standards.

Automation and Production Capacity

With a production capacity ranging from 500kg to 5 metric tons per shift, these machines are built for scalability.

By automating the intensive tasks of filtering and dehydrating, the system dramatically reduces manual labor and increases production speed. This ensures a consistent product quality that is difficult to achieve with manual methods, allowing an operation to grow efficiently.

Understanding the Trade-offs

While highly effective, a honey processing machine represents a significant operational decision. It is essential to weigh the benefits against the practical considerations.

The Upfront Investment

These are industrial machines, not hobbyist tools. The initial cost is substantial and should be evaluated in the context of a commercial business plan where increased volume and improved quality can justify the expense.

Operational Knowledge

While automated, the machine requires a knowledgeable operator. Properly managing the vacuum level and temperature settings is key to preserving honey quality. Incorrect operation could lead to over-processing, potentially stripping the honey of some of its unique character.

Maintenance and Cleaning

The system's components, including the pumps, filters, and tanks, require regular cleaning and maintenance to ensure food safety and prevent blockages. This adds an operational responsibility that is more demanding than that of simple manual setups.

Making the Right Choice for Your Operation

Selecting the right features depends entirely on your primary business goals.

- If your primary focus is premium quality and consistency: The low-temperature vacuum concentration feature is non-negotiable, as it is the only way to reduce water content while protecting the honey's natural enzymes and flavor profile.

- If your primary focus is efficiency and business growth: The level of automation and the stated production capacity (kg per shift) are your most important metrics, as they directly impact labor costs and scalability.

- If your primary focus is food safety and long-term durability: Prioritize machines constructed entirely from high-grade 304 stainless steel, as this ensures compliance and a long operational life.

Ultimately, investing in the right processing machine transforms honey production from a manual craft into a scalable, quality-driven business.

Summary Table:

| Feature | Key Component | Primary Benefit |

|---|---|---|

| Viscosity Control | Preheating Tank | Enables smooth flow, protects flavor |

| Impurity Removal | Mechanical Filters | Removes wax, debris for purity |

| Moisture Control | Low-Temperature Vacuum Concentrator | Preserves enzymes, prevents nutrient loss |

| Durability & Safety | 304 Stainless Steel Construction | Ensures food safety, long lifespan |

| Efficiency | Automated System | Reduces labor, increases output (500kg-5T/shift) |

Ready to scale your honey production with the right equipment?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the robust, food-grade honey processing machinery you need to ensure product purity, increase efficiency, and grow your business.

We understand the critical balance between quality and scalability. Let us help you select the perfect machine for your operation's specific goals.

Contact HONESTBEE today for expert advice and wholesale pricing on reliable beekeeping equipment.

Visual Guide

Related Products

- HONESTBEE Commercial Upright Honey Melter

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

People Also Ask

- What is the purpose of heating honey to 35-40°C during pretreatment? Optimize Viscosity for Precise Analysis

- How can honey processing equipment address consumer biases? Transform Crystallized Honey into Premium Creamed Products

- What are the methods for heating honey? Preserve Quality and Improve Workability

- How to fix solidified honey? A Beekeeper's Guide to Gentle Re-liquefaction

- How many times can you decrystallize honey? The truth about quality loss with each cycle.