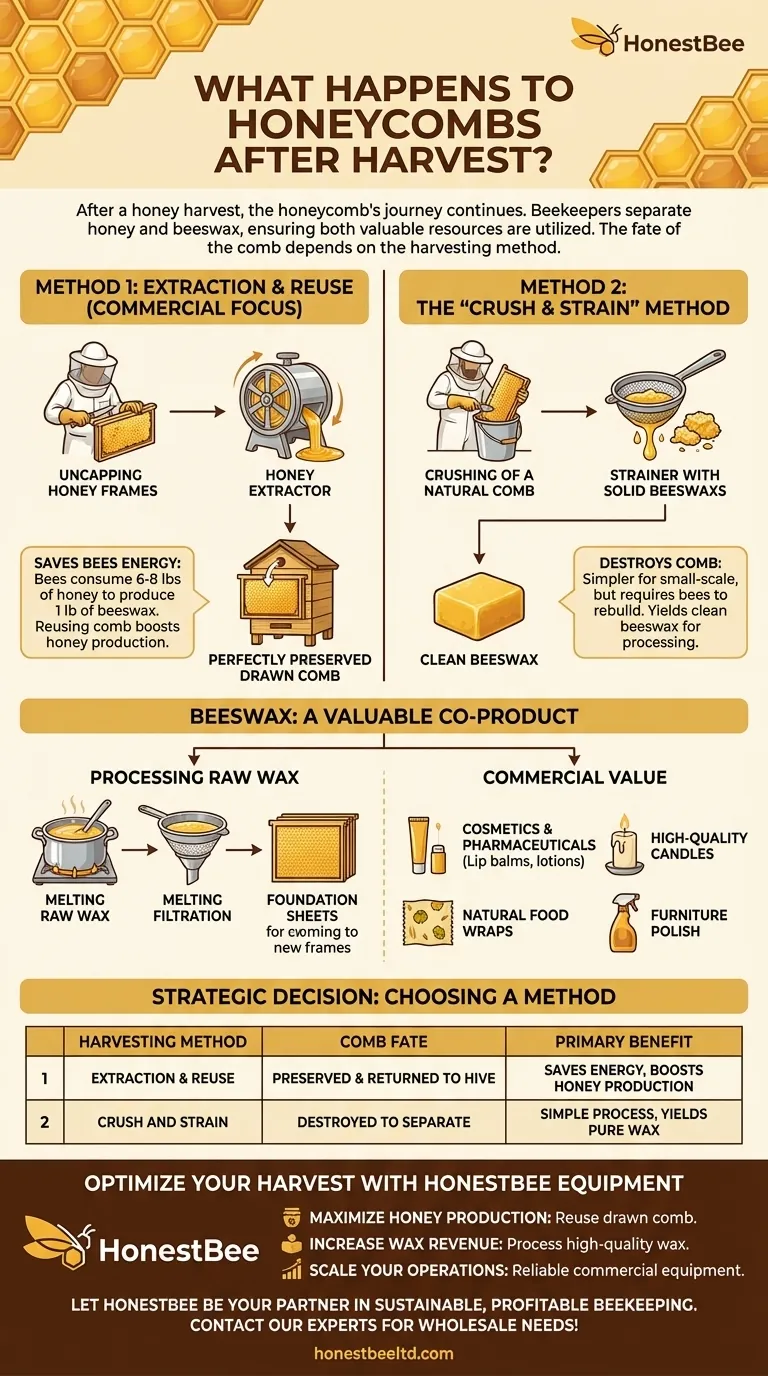

After a honey harvest, the honeycomb's journey is far from over. Beekeepers carefully separate the honey from the beeswax, ensuring that both valuable resources are put to good use. The fate of the physical comb structure, however, depends entirely on the beekeeper's harvesting method.

The central principle of modern beekeeping is resource efficiency. Most often, the honeycomb is carefully preserved and returned to the hive, saving the bees immense energy. When the comb is harvested, the resulting beeswax is a valuable co-product used in countless industries.

The Two Fates of a Honeycomb: Extraction vs. Recycling

A beekeeper’s goal is to harvest honey with minimal disruption to the colony. This has led to two primary methods for handling honeycomb, each with a different outcome for the wax structure.

Method 1: Extraction and Reuse of the Comb

For most beekeepers using modern Langstroth hives, preserving the comb is the top priority. The process involves carefully uncapping the wax cells and spinning the frames in a centrifuge.

This device, called a honey extractor, uses centrifugal force to sling the honey out of the cells while leaving the intricate wax structure almost entirely intact.

These empty but perfectly formed combs are called "drawn comb." They are then returned to the hive for the bees to refill. This gives the colony a massive head start, as they can immediately begin storing new nectar instead of spending energy rebuilding their home.

Method 2: The "Crush and Strain" Method

In some types of beekeeping, such as with top-bar hives or when harvesting natural comb, frames are not used. In these cases, the entire honeycomb is cut out.

The beekeeper then crushes the entire comb and strains the mixture through a filter or cheesecloth. This process separates the liquid honey from the solid pieces of beeswax.

While this method destroys the comb, it is simpler for small-scale or hobbyist beekeepers and yields a clean batch of beeswax for processing.

What Happens to the Harvested Beeswax?

Whether it comes from the thin cappings sliced off before extraction or from the crush and strain method, the collected beeswax is a valuable asset.

Processing the Raw Wax

The raw wax is gently melted and filtered to remove any remaining honey, pollen, or other impurities. This results in clean, pure blocks of beeswax.

Beekeepers often use this rendered wax to create foundation sheets—thin sheets of beeswax imprinted with a honeycomb pattern. These sheets are inserted into new frames to give the bees a guide for building straight, uniform comb, improving hive management.

The Commercial Value of Beeswax

The remaining beeswax is often sold for a wide range of commercial and artisanal uses. Its unique properties make it a sought-after ingredient in products like:

- Cosmetics and pharmaceuticals (lip balms, lotions)

- High-quality, clean-burning candles

- Natural food wraps

- Furniture polish and leather conditioning

Understanding the Trade-offs

Choosing a method isn't arbitrary; it's a strategic decision based on the beekeeper's goals, equipment, and philosophy.

The Energy Equation for Bees

Producing wax is incredibly energy-intensive for honey bees. It is estimated that bees consume 6 to 8 pounds of honey to produce just one pound of beeswax.

Reusing drawn comb is therefore the most energy-efficient practice for the colony. It frees up the bees' resources to focus on foraging and producing a larger honey surplus.

Equipment and Scale

Honey extractors represent a significant financial investment and are best suited for beekeepers managing multiple hives. For a hobbyist with one or two hives, the simplicity of the crush and strain method often outweighs the benefits of preserving the comb.

Purity and Specialty Products

Some consumers seek out "comb honey," where a piece of the honeycomb, still filled with honey, is sold as a complete product. This is the most natural form of honey consumption and bypasses the need for any extraction at all.

Making the Right Choice for Your Goal

The handling of honeycomb reflects a beekeeper's partnership with the colony, balancing harvest needs with the health of the bees.

- If your primary focus is colony health and maximizing honey production: Reusing drawn comb via centrifugal extraction is the most effective strategy, as it conserves the bees' energy.

- If your primary focus is harvesting beeswax or practicing foundationless beekeeping: The crush and strain method is a direct way to render both honey and wax, though it requires the bees to rebuild their comb.

- If your primary focus is a natural, unprocessed product: Selling comb honey directly to consumers preserves the structure entirely and offers a premium item.

Ultimately, beekeeping treats the honeycomb not as a disposable byproduct, but as a valuable asset to be intelligently managed and fully utilized.

Summary Table:

| Harvesting Method | Comb Fate | Primary Benefit |

|---|---|---|

| Extraction & Reuse | Comb is preserved and returned to the hive | Saves bees energy, boosts honey production |

| Crush and Strain | Comb is destroyed to separate wax and honey | Simple process, yields pure beeswax |

Optimize your honey harvest and wax yield with the right equipment from HONESTBEE.

As a commercial beekeeper or distributor, efficient resource management is key to your profitability. Our wholesale-focused supplies, including durable honey extractors and foundation tools, are designed to help you:

- Maximize Honey Production: Reuse drawn comb to save your bees energy.

- Increase Wax Revenue: Efficiently process high-quality beeswax for additional income.

- Scale Your Operations: Reliable equipment built for commercial apiaries.

Let HONESTBEE be your partner in sustainable, profitable beekeeping. Contact our experts today to discuss your wholesale needs!

Visual Guide

Related Products

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the features of a motorized honey extractor? Boost Efficiency and Precision in Your Honey Harvest

- What are the advantages of automated honey extraction machinery? Scale Your Apiary Efficiency

- How does high-efficiency honey extraction equipment contribute to the annual yield? Unlock 50kg+ Per Colony Yields

- How do mobile apiary platforms contribute to maximizing honey yield? Scale Fireweed Nectar Production Efficiency

- What technical advantages do electric honey extractors offer? Boost Efficiency & Preserve Your Honeycomb