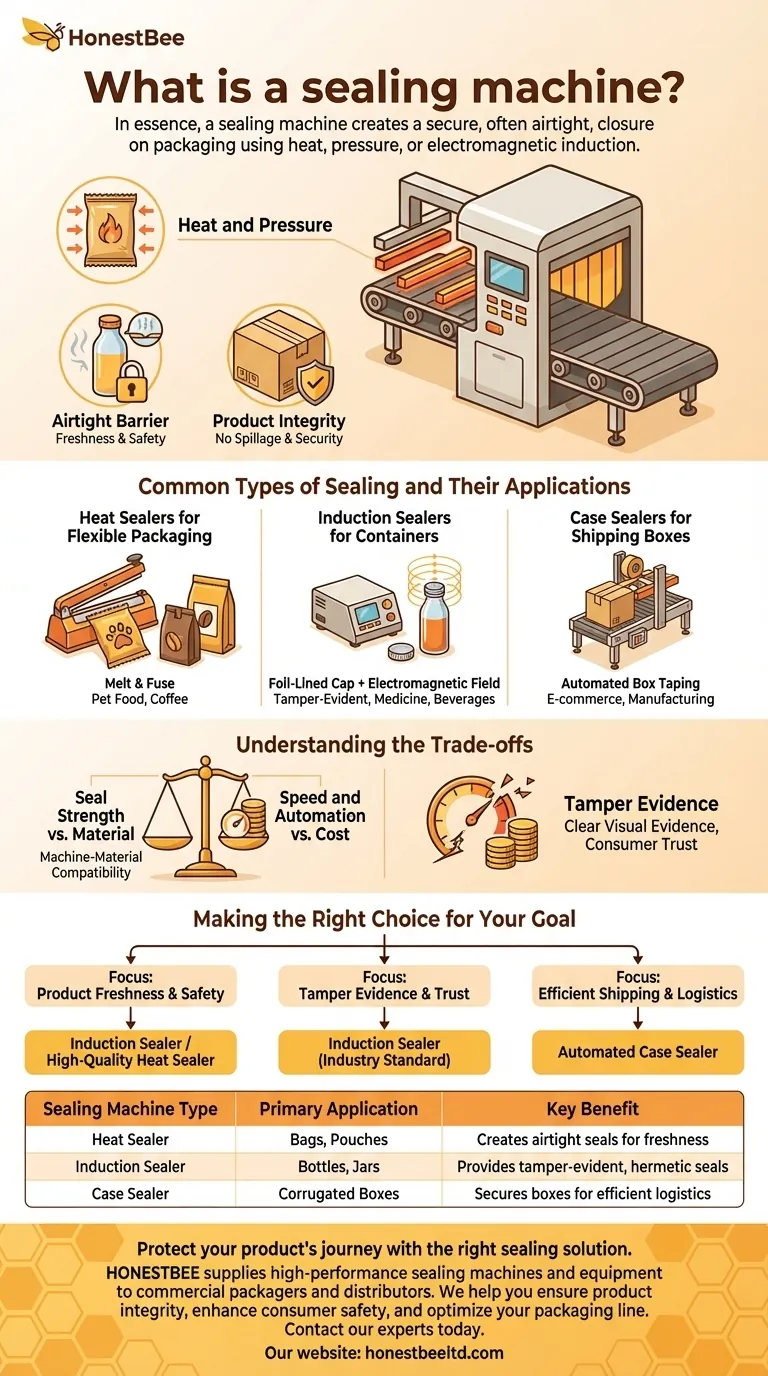

In essence, a sealing machine is a device engineered to create a secure, often airtight, closure on packaging. By applying methods like heat, pressure, or electromagnetic induction, these machines bond packaging materials together to protect the contents from contamination, prevent leakage, and ensure product integrity from the factory to the end user.

The true purpose of a sealing machine extends far beyond simply closing a container. It is a critical manufacturing step that preserves product quality, ensures consumer safety, and protects the value of the goods inside against environmental and physical hazards.

The Core Function: How Sealing Machines Work

A seal is the primary barrier between a product and the outside world. Sealing machines create this barrier with precision and reliability, but the underlying principles are straightforward.

The Principle of Heat and Pressure

The most common method involves applying a precise amount of heat to melt a sealant layer on the packaging material. Immediately following, pressure is applied to fuse the melted surfaces together, creating a strong, continuous bond as it cools.

This process is fundamental to sealing flexible packaging like bags and pouches.

Creating an Airtight Barrier

A properly formed seal creates an airtight and moisture-proof barrier. This is essential for preventing the degradation of products, especially in the food industry, where oxygen and moisture can lead to spoilage, mold, and loss of freshness.

The seal effectively locks in quality and locks out contaminants.

Ensuring Product Integrity

Beyond protecting from the environment, a strong seal prevents the contents from leaking or spilling. For items shipped in boxes, sealing machines ensure the container remains closed, protecting it from damage and potential tampering during transit and handling.

Common Types of Sealing and Their Applications

The type of sealing machine used is dictated by the package and the product. Each method is optimized for a specific application.

Heat Sealers for Flexible Packaging

These machines are the workhorses for sealing bags and pouches made of thermoplastic materials. They are widely used for products like pet food, garden seeds, and coffee.

The sealer applies a heated bar or wire to melt and fuse the opening of the bag shut.

Induction Sealers for Containers

Induction sealing is a non-contact method used for bottles and jars. It works by placing a foil-lined cap onto the container. The container then passes through an electromagnetic field, which induces an electrical current in the foil.

This current rapidly heats the foil, melting its sealant layer and bonding it securely to the rim of the container's opening. This creates a powerful, tamper-evident seal common on medicine, beverages, and sauces.

Case Sealers for Shipping Boxes

Often referred to as box tapers, these machines automate the process of sealing corrugated boxes with tape. They are essential for any high-volume shipping operation, from e-commerce fulfillment centers to industrial manufacturing plants.

Their goal is not airtightness but structural security for shipping and handling.

Understanding the Trade-offs

Choosing a sealing method requires balancing cost, speed, and the specific protection your product needs. Not every seal is appropriate for every product.

Seal Strength vs. Material

The effectiveness of a seal is entirely dependent on the compatibility between the machine and the packaging material. Using the wrong type of plastic with a heat sealer will result in a weak or nonexistent bond.

Similarly, an induction sealer is useless without a container equipped with a compatible foil-lined cap.

Speed and Automation vs. Cost

A simple tabletop heat sealer is inexpensive but slow, suitable for small-batch production. A fully automated induction sealing line is a significant capital investment but can seal thousands of units per hour with high reliability.

The required throughput of your operation is a primary factor in the decision.

Tamper Evidence as a Critical Feature

An induction seal or a shrink band provides clear visual evidence if a product has been opened. A simple heat-sealed bag or taped box does not.

For pharmaceuticals, food, and other sensitive goods, a tamper-evident seal is not a bonus feature—it is a requirement for consumer safety and trust.

Making the Right Choice for Your Goal

Your product and its journey to the customer will determine the ideal sealing solution.

- If your primary focus is product freshness and safety: An induction sealer for rigid containers or a high-quality heat sealer for bags is essential to create an airtight, protective barrier.

- If your primary focus is tamper evidence and consumer trust: Induction sealing is the industry standard for providing a clear, reliable, and hermetic seal on bottles and jars.

- If your primary focus is efficient shipping and logistics: An automated case sealer is the most effective solution for securing corrugated boxes against the rigors of transit.

Ultimately, selecting the right sealing machine is an investment in protecting your product's quality and your brand's reputation.

Summary Table:

| Sealing Machine Type | Primary Application | Key Benefit |

|---|---|---|

| Heat Sealer | Bags, Pouches (Flexible Packaging) | Creates airtight seals for freshness |

| Induction Sealer | Bottles, Jars (Rigid Containers) | Provides tamper-evident, hermetic seals |

| Case Sealer | Corrugated Shipping Boxes | Secures boxes for efficient logistics |

Protect your product's journey with the right sealing solution. HONESTBEE supplies high-performance sealing machines and equipment to commercial packagers and distributors. We help you ensure product integrity, enhance consumer safety, and optimize your packaging line. Contact our experts today to find the perfect sealing solution for your operation.

Visual Guide

Related Products

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Automatic Continuous Heat Sealing Machine

- Professional Durable Customizable Blister Packing Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- How does a bottle sealing machine work? Ensure Tamper-Evident, Hermetic Seals for Your Products

- How does tamper-evident sealing equipment benefit the honey trade? Ensure Product Integrity and Market Trust

- What is the principle of bottle sealing machine? Achieve Perfect, Tamper-Evident Seals for Your Products

- How do tamper-evident seals and anti-counterfeiting labels benefit bee product security? Ensure Total Honey Integrity

- How does an induction sealing machine work? Enhance Honey Packaging with Hermetic Seals & Tamper Evidence