At its core, a syrup filling machine is a specialized piece of equipment designed to accurately and efficiently dispense viscous liquids like syrup, honey, or sauces into containers. These machines use precise mechanisms to ensure every bottle or jar receives a consistent volume of product, automating a critical step in the packaging process.

The true purpose of a syrup filling machine is not just to fill containers, but to introduce precision, speed, and hygienic control into your production line. It transforms a manual, variable process into a reliable and scalable operation.

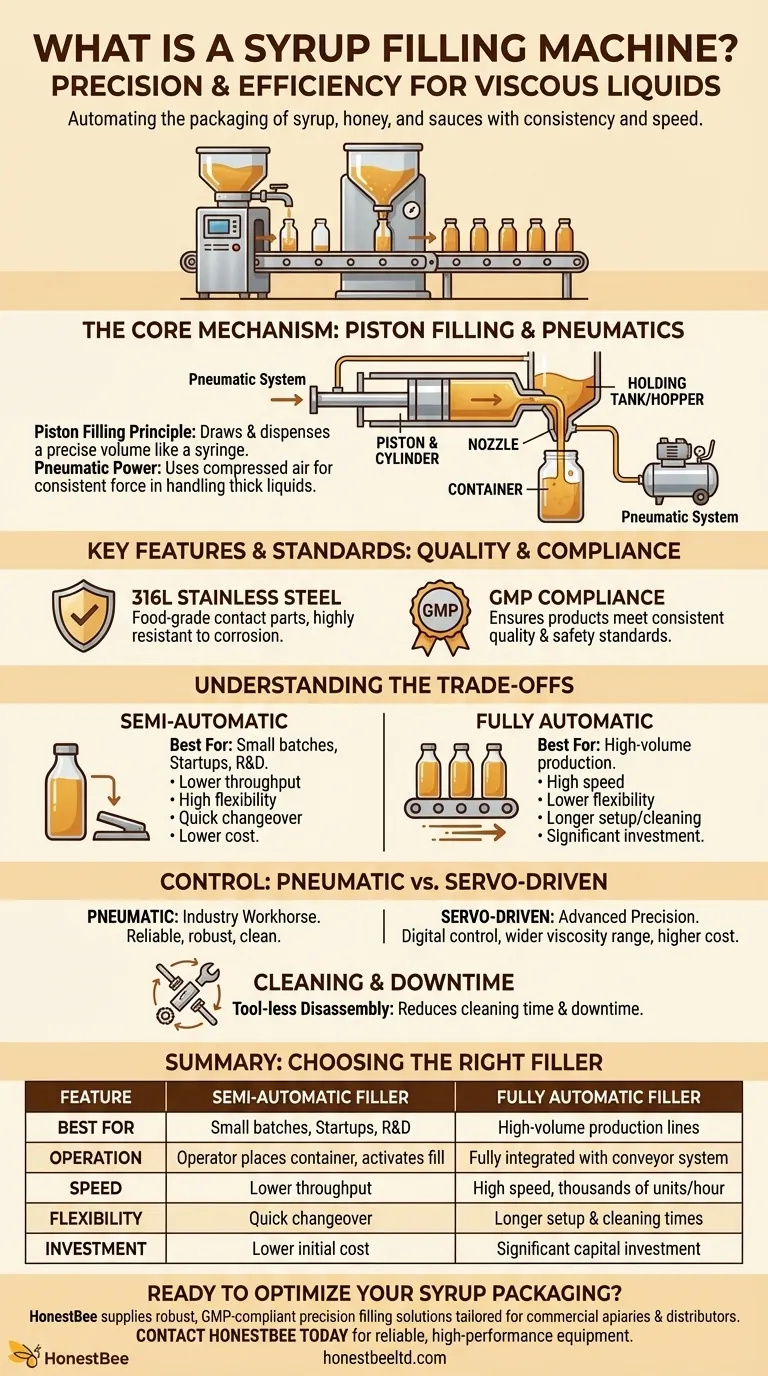

How Syrup Filling Machines Work: The Core Mechanisms

To understand their value, you must first understand the fundamental technology that powers them. These machines are engineered specifically to handle the challenges posed by thick, slow-moving liquids.

The Piston Filling Principle

The most common and effective method for viscous products is piston filling. Imagine a large, precise syringe. A piston pulls back, drawing a specific, measured volume of syrup from a holding tank (or hopper) into a cylinder.

The piston then pushes forward, dispensing that exact amount of syrup through a nozzle and into your container. The volume is controlled by the distance the piston travels, which can be adjusted for different fill sizes.

The Role of Pneumatics

Many syrup fillers are pneumatic, meaning they are powered by compressed air. As mentioned in the reference materials, advanced pneumatic elements are used to drive the piston's movement.

This method is highly reliable, robust, and clean, making it ideal for food and beverage environments. It provides the consistent force needed to move thick liquids smoothly.

Automation and Control

Machines can be semi-automatic or fully automatic. A semi-automatic machine requires an operator to place the container and activate the fill cycle, often with a foot pedal.

A fully automatic machine integrates with a conveyor system. It automatically positions, fills, and moves containers along the production line without human intervention, ensuring high speed and throughput.

Key Features and Material Standards

The design and materials of a filler are critical for performance, safety, and compliance.

Food-Grade Contact Parts

Any part of the machine that touches the syrup is known as a "contact part." These are almost universally made from 316L stainless steel.

This specific grade of steel is highly resistant to corrosion and will not react with food products. Other materials, like PTFE (Teflon), are often used for seals and linings because they are inert and reduce friction.

GMP Compliance

These material choices are essential for conforming to Good Manufacturing Practices (GMP). GMP is a system of standards that ensures products are consistently produced and controlled according to quality and safety regulations. Using a GMP-compliant machine is non-negotiable for commercial food production.

Understanding the Trade-offs

Choosing a machine involves balancing cost, speed, and flexibility. There is no single "best" filler; there is only the best filler for your specific application.

Throughput vs. Flexibility

A fully automatic, multi-head machine can fill thousands of containers per hour but represents a significant capital investment and requires more time for setup and cleaning.

A semi-automatic, single-head machine is far less expensive and can be changed over to different container sizes or products in minutes. Its lower speed makes it ideal for small businesses, startups, or R&D labs.

Pneumatic vs. Servo-Driven Control

While pneumatic systems are the industry workhorse, servo-driven fillers are a more advanced alternative. Instead of compressed air, they use highly precise electric servo motors to control the piston.

Servo fillers offer digital control over the fill speed and profile, allowing for even greater accuracy and the ability to handle a wider range of viscosities. However, they come at a higher initial cost.

Cleaning and Downtime

The more complex the machine, the longer it takes to clean. Look for machines designed for "tool-less" disassembly, which allows operators to quickly break down the contact parts for cleaning without needing special tools. This feature dramatically reduces downtime between production runs.

Making the Right Choice for Your Operation

Selecting the right syrup filler is a strategic decision that directly impacts your operational efficiency and ability to grow.

- If your primary focus is starting a small-batch operation: A semi-automatic, single-head pneumatic filler offers the best balance of cost, flexibility, and professional-grade precision.

- If your primary focus is scaling production and maximizing speed: A fully automatic, multi-head filling line is the necessary investment to achieve high throughput and minimize labor costs.

- If your primary focus is ultimate precision with expensive products: Consider a servo-driven filler for its superior digital control, which minimizes product waste and offers unparalleled repeatability.

Choosing the right filling technology is a foundational step toward building a more efficient, consistent, and profitable production process.

Summary Table:

| Feature | Semi-Automatic Filler | Fully Automatic Filler |

|---|---|---|

| Best For | Small batches, startups, R&D | High-volume production lines |

| Operation | Operator places container, activates fill | Fully integrated with conveyor system |

| Speed | Lower throughput | High speed, thousands of units/hour |

| Flexibility | Quick changeover for different products | Longer setup and cleaning times |

| Investment | Lower initial cost | Significant capital investment |

Ready to Optimize Your Syrup Packaging?

Choosing the right filling machine is crucial for the efficiency and growth of your operation. HONESTBEE supplies robust, GMP-compliant beekeeping supplies and equipment, including precision filling solutions tailored for commercial apiaries and beekeeping equipment distributors.

We understand the unique challenges of handling viscous products like honey and syrup. Our wholesale-focused operations ensure you get reliable, high-performance equipment that enhances your production line's speed, accuracy, and hygiene.

Contact HONESTBEE today to discuss your specific needs and discover how our filling solutions can drive your profitability and scalability.

Visual Guide

Related Products

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- How can contamination in filled honey be prevented? A 3-Step Strategy for Pure, Shelf-Stable Honey

- What value do automated honey-filling machines provide? Unlock Professional Scalability and Brand Value

- What are the characteristics of Semi-automated honey filling machines? Boost Efficiency for Growing Apiaries

- How do automatic honey filling machines contribute to beekeeping sustainability? Boost Your Apiary's ROI

- What is the importance of introducing automated filling and sealing machinery in the processing of stingless bee honey?

- What role does professional honey-filling machinery play in the commercial distribution and international export of honey?

- What technical advantages do automatic honey filling machines offer? Optimize Your Commercial Honey Bottling Today

- What processing challenges do honey filling machines address? Optimize Your Commercial Honey Production