The primary importance of ventilation when choosing an entrance reducer is its direct impact on moisture and temperature control within the hive. While a reducer’s main purpose is to limit access for defensive reasons, the size of its opening dictates the hive's ability to expel damp, stale air—a factor that is absolutely critical for the colony's health, especially during winter.

An entrance reducer must balance the need for hive defense with the non-negotiable requirement for air circulation. Improper ventilation from a poorly chosen reducer can trap excess moisture, which is a far greater threat to a colony's winter survival than cold alone.

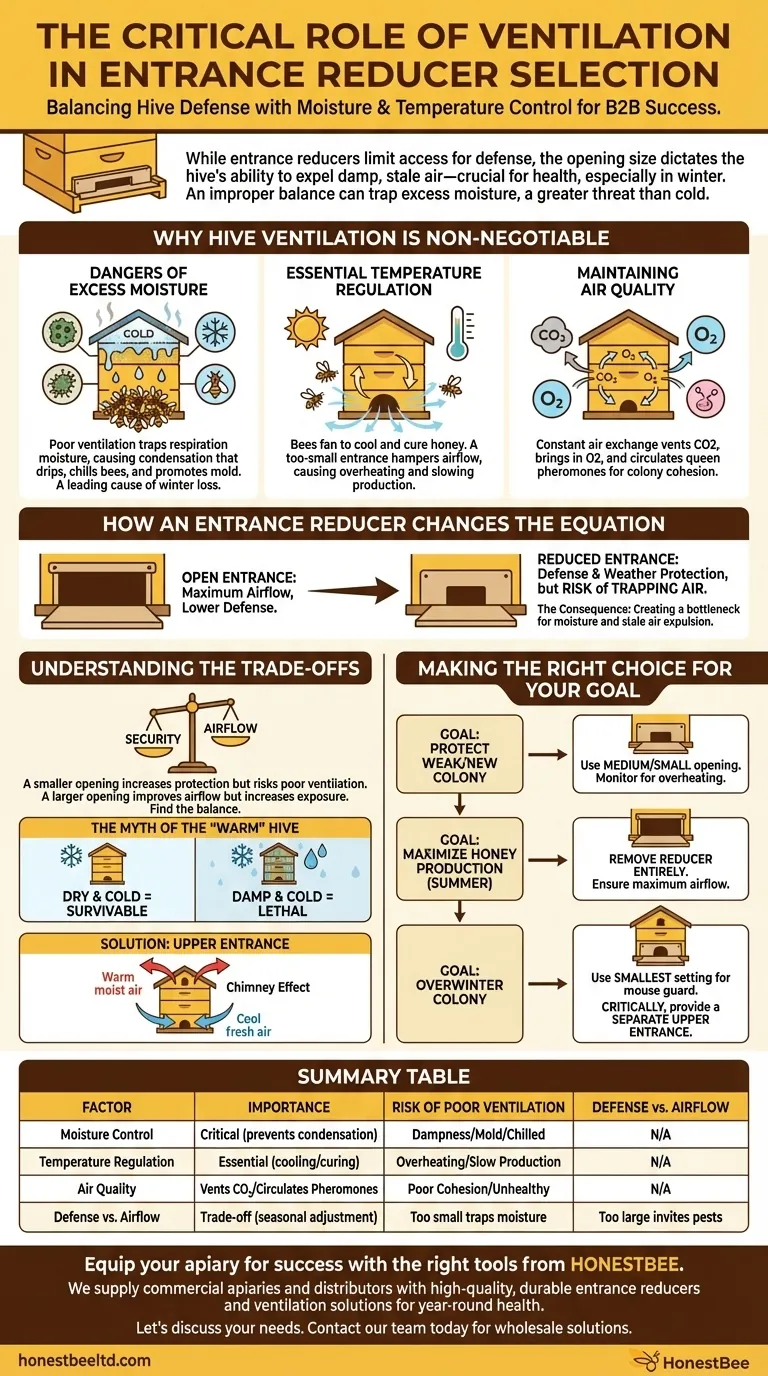

Why Hive Ventilation is Non-Negotiable

A beehive is a living, breathing superorganism that must actively manage its internal environment. Proper ventilation, facilitated by the hive entrance, is the primary mechanism for this regulation.

The Dangers of Excess Moisture

Bees constantly release water vapor through respiration. In a poorly ventilated hive, this warm, moist air rises, hits the cold inner cover, and condenses into water droplets.

This condensation can drip back down onto the bees, chilling the cluster and promoting the growth of mold and mildew on the comb. This damp environment is a leading cause of colony loss in the winter.

Essential Temperature Regulation

In the summer, bees actively cool the hive by fanning their wings at the entrance, creating an evaporative cooling effect. This is also crucial for curing nectar into honey, which requires reducing its water content.

An entrance that is too small can severely hamper their ability to move enough air, leading to overheating and slowing honey production.

Maintaining Air Quality

Constant air exchange is necessary to vent carbon dioxide and bring in fresh oxygen. It also helps circulate the queen's pheromones throughout the hive, which is vital for maintaining colony cohesion and social order.

How an Entrance Reducer Changes the Equation

An entrance reducer is a simple tool, but its impact on the complex dynamics of hive airflow is significant. Understanding its function is key to using it correctly.

The Primary Role: Defense

The main reason to use a reducer is to shrink the entrance to a size a colony can realistically defend. This is especially important for new, small, or weak colonies that are vulnerable to being robbed by stronger hives or attacked by pests like wasps.

The Secondary Role: Weather Protection

A smaller opening reduces drafts and helps the colony manage its internal temperature. Many beekeepers use them in winter with the intention of keeping the hive "warm."

The Unintended Consequence: Trapping Air

This is where the risk lies. By shrinking the main point of air exchange, a reducer can inadvertently create a bottleneck. It can prevent the colony from effectively pushing out the stale, moisture-laden air it generates.

Understanding the Trade-offs

Using an entrance reducer is not a simple "on or off" decision. It's a calculated trade-off between security and ventilation that must be adjusted based on the season and the colony's condition.

Security vs. Airflow

A very small opening offers maximum protection but poses the highest risk for poor ventilation. A larger opening provides better airflow but leaves the colony more exposed. The beekeeper's job is to find the right balance for the specific situation.

The Myth of the "Warm" Hive

A common mistake is to reduce the entrance too much in an effort to keep the hive warm. Bees do not heat the entire hive box; they heat their cluster. A dry, well-ventilated colony can easily survive very cold temperatures. A damp colony cannot. Dry and cold is survivable; damp and cold is lethal.

The Upper Entrance Solution

Many experienced beekeepers mitigate the ventilation risk by providing a small upper entrance or ventilation shim, especially in winter. This creates a "chimney effect," allowing warm, moist air to escape from the top while fresh, dry air is drawn in through the reduced bottom entrance.

Making the Right Choice for Your Goal

Your strategy for using an entrance reducer should adapt to the colony's needs throughout the year.

- If your primary focus is protecting a new or weak colony: Use a medium or small reducer opening to prevent robbing, but monitor closely for signs of overheating on warm days.

- If your primary focus is maximizing honey production in summer: Remove the reducer entirely from strong, established colonies to ensure maximum airflow for cooling and nectar curing.

- If your primary focus is overwintering a colony: Use the reducer on its smallest setting to prevent mice from entering, but critically ensure there is a separate upper entrance for moisture to escape.

Ultimately, managing your hive's entrance is about providing the right tool for the job at the right time to support the colony's natural ability to thrive.

Summary Table:

| Factor | Importance | Risk of Poor Ventilation |

|---|---|---|

| Moisture Control | Critical for winter survival; prevents condensation. | Dampness leads to mold, mildew, and chilled clusters. |

| Temperature Regulation | Essential for summer cooling and honey curing. | Overheating and slowed honey production. |

| Air Quality | Vents CO2, circulates oxygen and queen pheromones. | Poor social cohesion and unhealthy hive environment. |

| Defense vs. Airflow | A trade-off; requires seasonal adjustment. | Too small: traps moisture. Too large: invites pests. |

Equip your apiary for success with the right tools from HONESTBEE.

We supply commercial apiaries and beekeeping equipment distributors with high-quality, durable entrance reducers and ventilation solutions designed to support colony health year-round. Our wholesale-focused operations ensure you get the reliable equipment you need to help your bees thrive.

Let's discuss your needs. Contact our team today to get the right supplies for your operation.

Visual Guide

Related Products

- Beehive Entrance Reducer Guardian Metal Hive Entrance for Bees

- Multi-Functional Rotary Hive Entrance Disc for Beekeeping

- Multi-Functional Sliding Hive Entrance for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Insulated Winter Hive Wrap for Beekeeping

People Also Ask

- What should be done after transferring frames to the new hive? Essential Steps for a Secure Colony

- What are the features of the side with oblong holes in the entrance reducer? A Guide to Hive Defense & Health

- What are the different types of entrance reducers available? A Guide to Protecting Your Hive

- Why are specific wooden platforms installed at the hive entrance? Enhancing Guard Bee Behavioral Observation

- How can a Langstroth hive entrance be adjusted? Mimic Natural Bee Preferences for a Healthier Hive