At their core, sachet forming and packing machines are automated systems designed to take bulk products and package them into small, sealed packets, or "sachets." They are used extensively across the food, pharmaceutical, and chemical industries for packaging powders, granules, liquids, and pastes. The fundamental goal of this equipment is to significantly improve the efficiency, speed, and consistency of the packaging process.

The true purpose of a sachet machine extends beyond simply making packets. It is about transforming a manual, labor-intensive process into a highly efficient, automated workflow that ensures precise dosing, consistent sealing, and scalable production.

How Sachet Machines Drive Operational Value

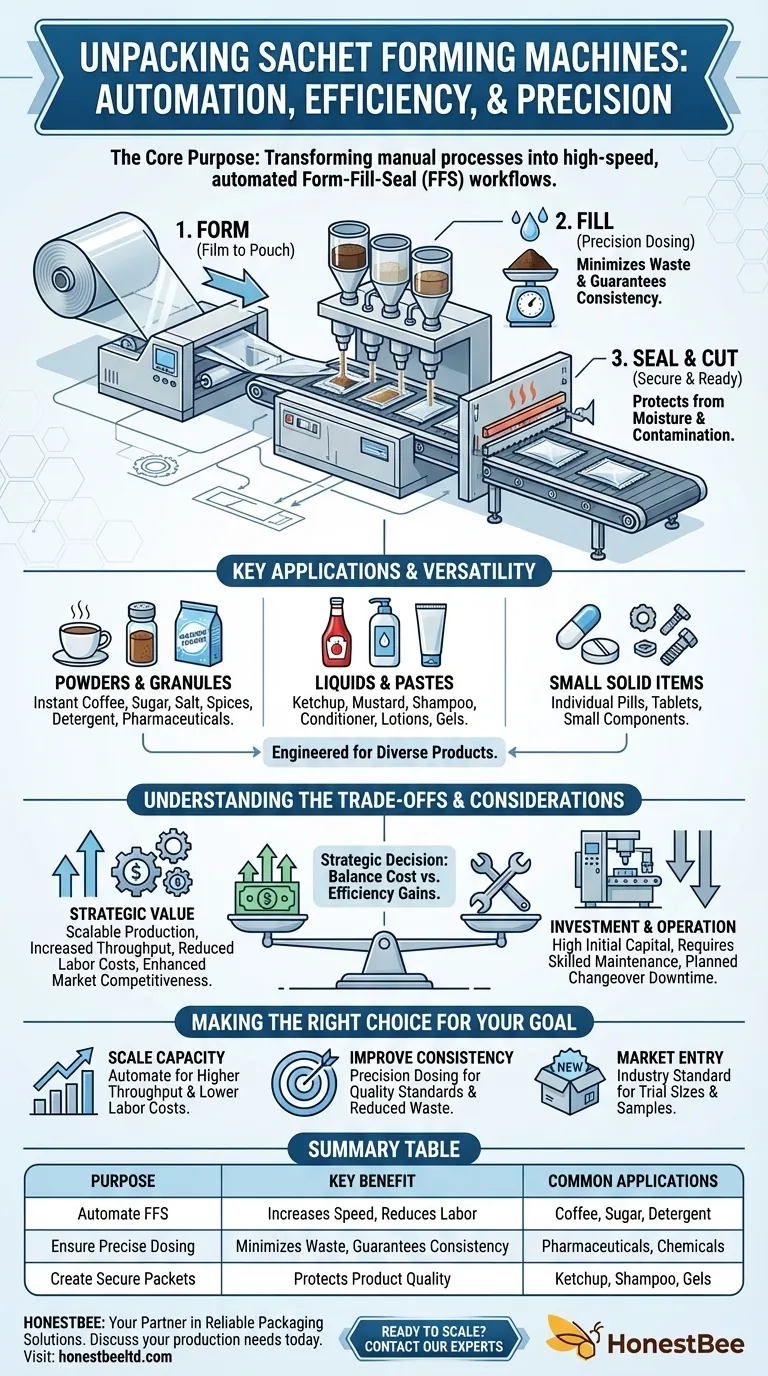

The core value of a sachet machine is rooted in its ability to automate a multi-step process into one continuous, high-speed operation. This is often referred to as the Form-Fill-Seal (FFS) cycle.

The Form-Fill-Seal (FFS) Principle

A roll of flat packaging film is fed into the machine. It is then formed into the shape of a pouch or sachet. This automated forming process is the first step in creating the package.

Precision Dosing and Filling

Once the sachet is formed, a dosing system dispenses a precise, pre-set amount of product into it. This is critical for both powders (like medicine or detergent) and liquids, as it minimizes product waste and guarantees consistency for the end consumer.

Automated Sealing and Cutting

After filling, the machine securely seals the sachet, often using heat and pressure, to protect the product from moisture, air, and contamination. Finally, the sealed sachets are cut into individual units, ready for boxing and distribution.

Key Applications and Product Versatility

While the provided reference focuses on powders and granules, these machines are highly versatile and are engineered to handle a wide range of product types.

Powders and Granules

This is a primary application. Sachet machines are ideal for single-serving products like instant coffee, sugar, salt, spices, detergent powder, and powdered pharmaceuticals.

Liquids and Pastes

With the appropriate dosing system (like a piston or pump filler), these machines are used for products like ketchup, mustard, shampoo, conditioner, lotions, and industrial gels.

Small Solid Items

Specialized sachet machines can also package small, uniform solid items, such as individual pills, tablets, or small hardware components.

Understanding the Trade-offs and Considerations

While highly effective, integrating a sachet machine is a strategic decision with important factors to weigh. Objectivity requires acknowledging potential challenges.

High Initial Capital Investment

These are sophisticated industrial machines, and the initial purchase price represents a significant capital expenditure. The return on investment must be carefully calculated based on projected increases in efficiency and labor savings.

Maintenance and Technical Skill

A sachet machine is a complex piece of equipment with many moving parts, sensors, and control systems. It requires trained operators for proper setup and troubleshooting, as well as a consistent preventative maintenance schedule to ensure reliability.

Changeover Downtime

Switching the machine from one product type or sachet size to another requires a changeover process. This involves cleaning, changing forming tools, and adjusting settings, which results in planned downtime that must be factored into production schedules.

Making the Right Choice for Your Goal

Adopting this technology should be directly tied to a specific business objective.

- If your primary focus is increasing production capacity: Automating your packaging line with a sachet machine is a direct path to higher throughput and reduced labor costs per unit.

- If your primary focus is improving product consistency: The precision dosing systems inherent in these machines will deliver a strong return by minimizing product waste and ensuring every sachet meets quality standards.

- If your primary focus is market entry with trial sizes: The sachet format is the industry standard for samples and single-serving products, making it an essential tool for consumer product launches.

Ultimately, integrating a sachet forming machine is a strategic investment in automation that unlocks scalability, consistency, and market competitiveness.

Summary Table:

| Purpose | Key Benefit | Common Applications |

|---|---|---|

| Automate Form-Fill-Seal (FFS) | Increases production speed & reduces labor costs | Instant coffee, sugar, spices, detergent |

| Ensure Precise Dosing | Minimizes product waste & guarantees consistency | Pharmaceuticals, powdered supplements, chemicals |

| Create Secure, Sealed Packets | Protects product from moisture & contamination | Ketchup, shampoo samples, lotions, industrial gels |

Ready to scale your packaging operation with precision and efficiency?

As a leading supplier to commercial apiaries and distributors, HONESTBEE understands the critical need for reliable, high-performance equipment that drives profitability. A sachet forming machine is a strategic investment in automating your workflow, reducing waste, and ensuring product consistency—whether you're packaging powders, liquids, or pastes.

Let's discuss how integrating the right packaging solution can enhance your production capacity and market competitiveness. Contact our experts today for a tailored consultation.

Visual Guide

Related Products

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Durable Customizable Blister Packing Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- What are the technical advantages of using automated honey filling machinery? Boost Precision and Hygiene

- What is the role of automated honey filling and processing equipment in maintaining product quality? Protect Your Harvest

- How does an industrial-grade honey sachet packaging machine assist beekeepers in accessing public institution markets?

- What are the primary advantages of automated honey-filling machinery? Boost Efficiency and Ensure Product Purity

- How does automated filling equipment ensure product quality? Precision Packaging for Honey Purity