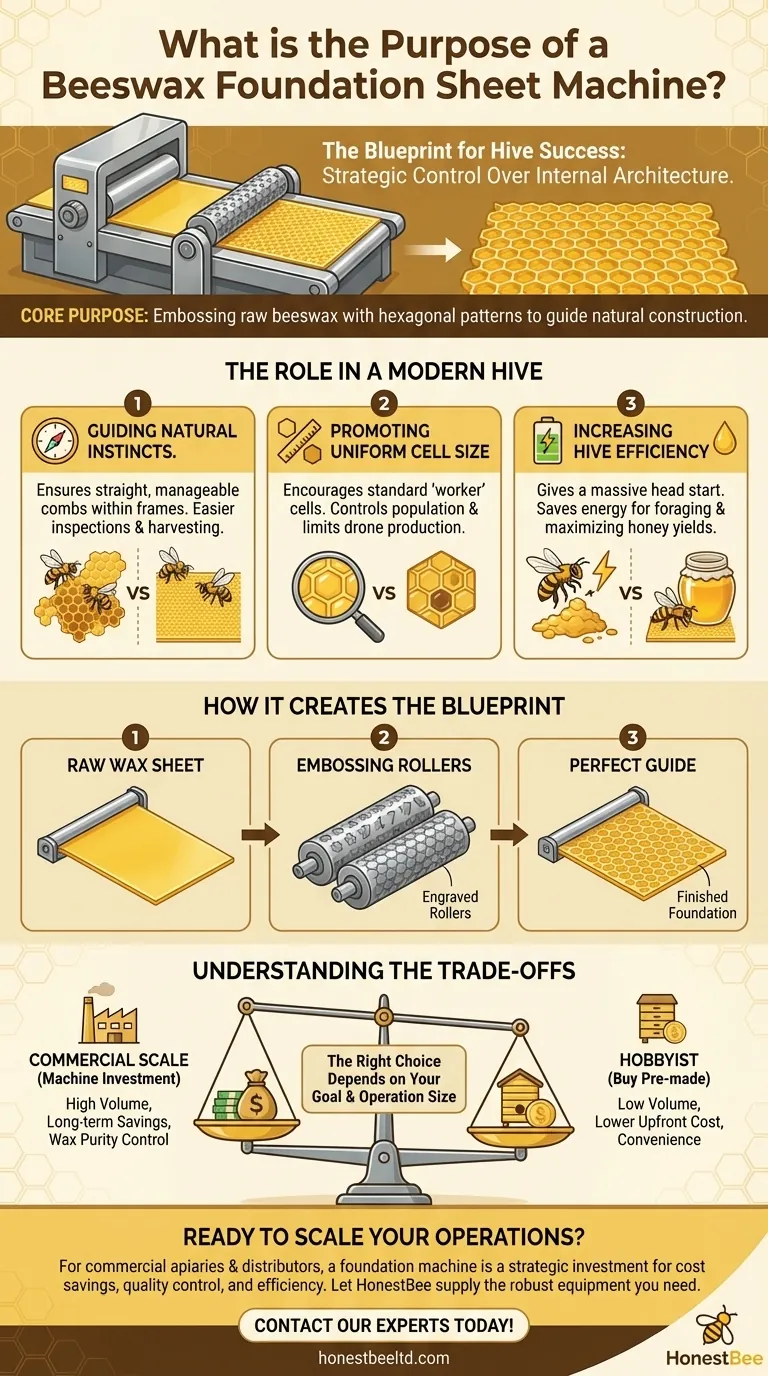

Fundamentally, a beeswax foundation sheet machine is specialized equipment used to produce the patterned wax sheets that form the structural base of honeycombs. These machines take raw, rendered beeswax and emboss it with the hexagonal cell pattern that bees recognize and build upon. This provides a precise blueprint for the bees, guiding their natural construction instincts.

The core purpose of a foundation machine is not merely to create wax sheets; it is to give the beekeeper strategic control over the hive's internal architecture. By providing a uniform, pre-patterned base, the machine directs the bees' immense energy toward efficient honey production and brood rearing, minimizing wasted effort on irregular comb construction.

The Role of Foundation in a Modern Hive

A sheet of beeswax foundation is essentially a "starter guide" for the colony. While bees are perfectly capable of building their own comb from scratch, providing foundation solves several critical problems and enhances the beekeeper's ability to manage the hive.

Guiding Natural Instincts

Bees naturally secrete wax and build comb to store honey and raise their young. However, without a guide, this "free-drawn" comb can be irregular, curved, and difficult for the beekeeper to inspect or manage.

Foundation provides a flat, stable plane, encouraging bees to build straight combs within the removable frames. This makes hive inspections and honey harvesting significantly easier.

Promoting Uniform Cell Size

The machine's rollers emboss a perfect hexagonal pattern onto the wax. This encourages the bees to build uniform, standard-sized "worker" cells.

Controlling cell size is crucial for managing the hive's population. It helps maximize the space for raising worker bees, the hive's primary labor force, and can limit the production of larger "drone" cells for male bees.

Increasing Hive Efficiency

Building comb is an energy-intensive process for bees, requiring them to consume significant amounts of honey. By providing a foundation, the beekeeper gives the colony a massive head start.

The bees can immediately begin drawing out the cell walls from the embossed base instead of having to construct the entire structure from scratch. This saved energy is redirected towards foraging for nectar and producing more honey.

How the Machine Creates the Blueprint

The design of a foundation machine is simple but highly effective. It translates the beekeeper's need for uniformity into a language the bees understand.

The Embossing Rollers

The heart of the machine is a pair of heavy, engraved rollers set horizontally in a frame. The surface of each roller is a mirror image of a perfect honeycomb pattern.

The Imprinting Process

A smooth, thin sheet of pre-warmed beeswax is fed between these two rollers. As it passes through, the immense pressure imprints the hexagonal cell base pattern deeply into both sides of the wax sheet.

The Result: A Perfect Guide

The final product is a uniform beeswax foundation sheet. It is rigid enough to be installed in a frame but soft enough for the bees to immediately begin working and building upon it, creating the strong, straight combs desired for a healthy and productive hive.

Understanding the Trade-offs

While foundation is a cornerstone of modern beekeeping, the decision to make your own involves clear trade-offs.

Cost vs. Scale

A foundation machine is a significant financial investment. For a commercial beekeeper with dozens or hundreds of hives, the cost is quickly offset by the savings from not having to purchase foundation sheets. For a hobbyist with only a few hives, buying pre-made foundation is far more economical.

Control Over Wax Purity

Making your own foundation gives you absolute control over the quality of your wax. You can use clean cappings wax harvested from your own hives, ensuring it is free from contaminants. Commercially produced foundation can sometimes contain residues from agricultural chemicals or miticides used in other apiaries.

The "Foundationless" Alternative

Some beekeepers prefer to practice "foundationless" beekeeping, where bees are encouraged to build their own natural comb without any guide. This can result in more varied cell sizes but often leads to irregular, cross-built combs that are difficult to inspect and may break during honey extraction.

Making the Right Choice for Your Goal

The decision to invest in a foundation machine depends entirely on the scale and philosophy of your beekeeping operation.

- If your primary focus is large-scale honey production: Owning a machine offers significant cost savings and ensures a consistent supply of high-quality foundation for hive expansion.

- If your primary focus is hobby beekeeping: Buying pre-made foundation sheets is almost always the more practical and cost-effective choice for a small number of hives.

- If your primary focus is self-sufficiency and wax purity: A machine provides complete control over your inputs, allowing you to recycle your own clean wax into new foundation year after year.

Ultimately, a beeswax foundation machine empowers a beekeeper to actively manage a hive's resources for maximum health and productivity.

Summary Table:

| Aspect | Purpose of a Foundation Machine |

|---|---|

| Primary Function | Embosses raw beeswax with a hexagonal cell pattern to create a structural base for honeycombs. |

| Key Benefit | Guides bees to build straight, uniform comb, making hive inspection and honey harvesting easier. |

| Target User | Commercial apiaries and distributors seeking cost savings, wax purity, and operational control at scale. |

| Trade-off | Significant upfront investment; ideal for large-scale operations, not small hobbyist setups. |

Ready to take control of your hive's productivity and wax purity?

For commercial apiaries and beekeeping equipment distributors, producing your own foundation with a dedicated machine is a strategic investment. It leads to significant long-term cost savings, ensures the highest quality wax from your own hives, and provides complete control over your supply chain.

HONESTBEE supplies the robust, wholesale-focused beekeeping equipment you need to scale your operations efficiently. Let's discuss how a foundation machine can benefit your business. Contact our experts today!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production