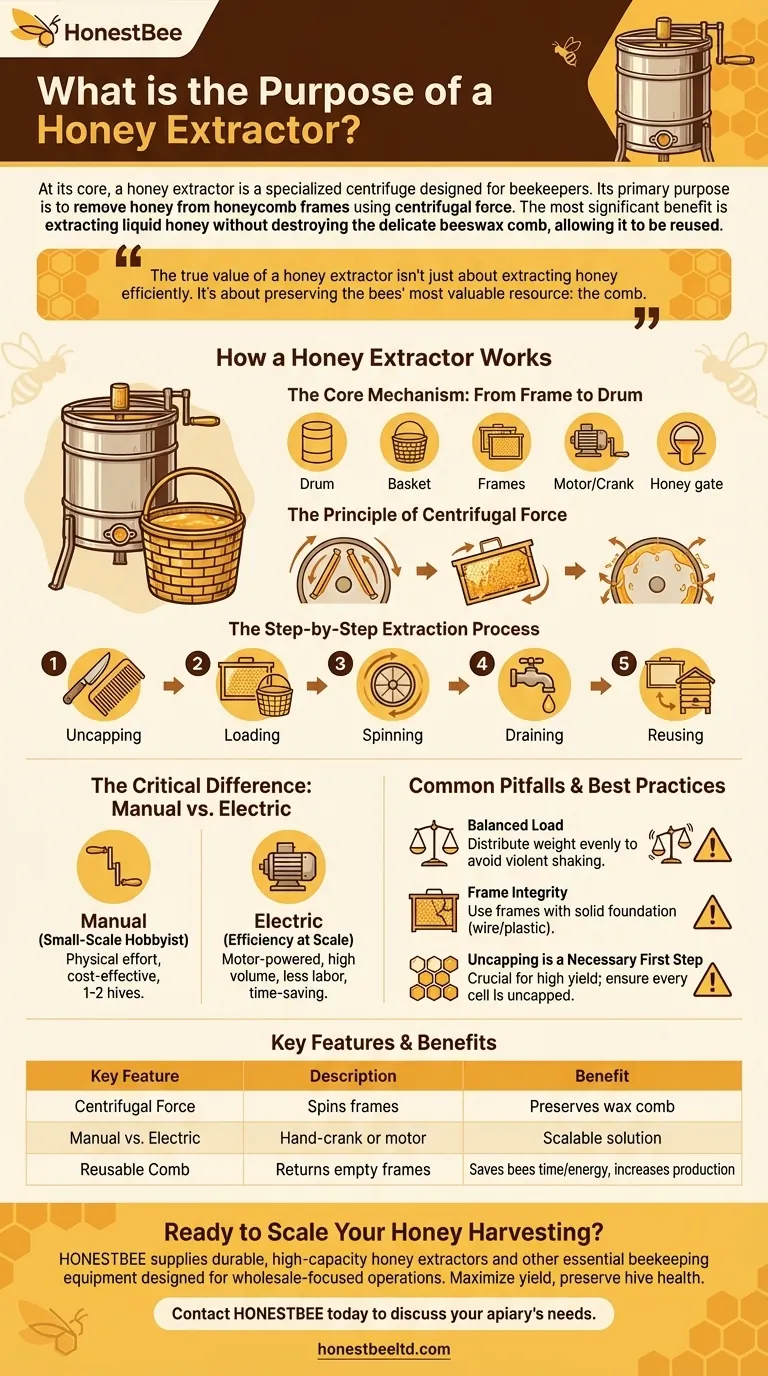

At its core, a honey extractor is a specialized centrifuge designed for beekeepers. Its primary purpose is to remove honey from the honeycomb frames using centrifugal force. The most significant benefit of this method is its ability to extract the liquid honey without destroying the delicate beeswax comb, allowing it to be reused by the bees.

The true value of a honey extractor isn't just about extracting honey efficiently. It's about preserving the bees' most valuable resource: the comb. By returning intact combs to the hive, beekeepers save their colony immense time and energy, allowing them to focus on producing more honey.

How a Honey Extractor Works

The Core Mechanism: From Frame to Drum

A honey extractor consists of a large drum, typically stainless steel, with a basket inside designed to hold honeycomb frames. This basket is connected to a mechanism—either a hand crank or an electric motor—that spins it at high speed. A tap, or honey gate, is located at the bottom of the drum to drain the collected honey.

The Principle of Centrifugal Force

The entire operation relies on centrifugal force. As the basket spins, the frames are rapidly rotated, flinging the honey outwards from the uncapped hexagonal cells. The honey strikes the inner wall of the drum, runs down to the bottom, and collects there for draining.

The Step-by-Step Extraction Process

- Uncapping: The beekeeper first uses a special knife or tool to carefully slice off the thin layer of wax "cappings" that bees build to seal the honey in each cell.

- Loading: The uncapped frames are placed into the slots in the extractor's basket.

- Spinning: The basket is spun, building up speed. The centrifugal force drives the honey out of the cells.

- Draining: Once the extraction is complete, the pure, raw honey is drained from the tap at the bottom of the drum.

- Reusing: The now-empty (but intact) frames are returned to the hive for the bees to clean, repair, and refill.

The Critical Difference: Manual vs. Electric

For the Small-Scale Hobbyist

Manual extractors are operated with a hand crank. They are an excellent, cost-effective choice for beekeepers with only one or two hives, but they require significant physical effort to operate.

For Efficiency at Scale

Electric extractors perform the same function but are powered by a motor. With the simple flip of a switch, they can process a much larger number of frames with virtually no physical labor. Models range in size, holding anywhere from two to over one hundred frames at once, making them essential for commercial operations and serious hobbyists.

The Impact on Labor and Time

The primary advantage of an electric model is its dramatic reduction in both labor and time. What might take hours of manual cranking can be accomplished automatically in a fraction of the time, freeing the beekeeper to manage other apiary tasks.

Common Pitfalls and Best Practices

The Importance of Balancing Your Load

An extractor must be loaded with frames of similar weight, distributed evenly around the basket. An unbalanced load will cause the machine to shake violently during operation, potentially damaging the extractor, the frames, or both.

Why Frame Integrity is Non-Negotiable

Only use frames with a solid foundation, such as those with wire or plastic supports. Frames built on foundationless comb are often too fragile and can break apart under the intense force of the extraction process.

Uncapping is a Necessary First Step

The extractor cannot pull honey through sealed wax cappings. Ensuring every cell is properly uncapped before spinning is crucial for achieving a high honey yield from each frame.

Making the Right Choice for Your Apiary

Choosing whether and what kind of extractor to use depends entirely on the scale and goals of your beekeeping.

- If you manage one or two hobby hives: A small manual extractor preserves your comb without the expense of an electric model.

- If you are a growing beekeeper or run a small business: An electric extractor is a crucial investment for efficiency and scalability.

- If your primary focus is hive health and productivity: Using any extractor to return undamaged comb to your bees is one of the most effective ways to boost their honey production.

Ultimately, the honey extractor transforms harvesting from a potentially destructive task into a sustainable and efficient part of the beekeeping cycle.

Summary Table:

| Key Feature | Description | Benefit |

|---|---|---|

| Centrifugal Force | Spins frames to fling honey out of cells. | Preserves the wax comb for reuse by bees. |

| Manual vs. Electric | Hand-crank or motor-powered operation. | Scalable solution for hobbyists to commercial apiaries. |

| Reusable Comb | Returns empty, intact frames to the hive. | Saves bees time and energy, increasing honey production. |

Ready to Scale Your Honey Harvesting?

As a commercial beekeeper or equipment distributor, efficiency is paramount. HONESTBEE supplies durable, high-capacity honey extractors and other essential beekeeping equipment designed for wholesale-focused operations. Our products help you maximize yield while preserving the health of your hives.

Contact HONESTBEE today to discuss your apiary's needs and discover how our wholesale solutions can boost your productivity.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- How to extract honey by hand? A Guide to Crush & Strain vs. Manual Extractors

- What is a fun and easy alternative to using a honey extractor for harvesting honey? Try the Crush and Strain Method

- What is the principal idea in harvesting honey? A 3-Step Guide to a Responsible Harvest

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive

- How much honey does a beekeeper extract from the hive? A Guide to Sustainable Harvesting