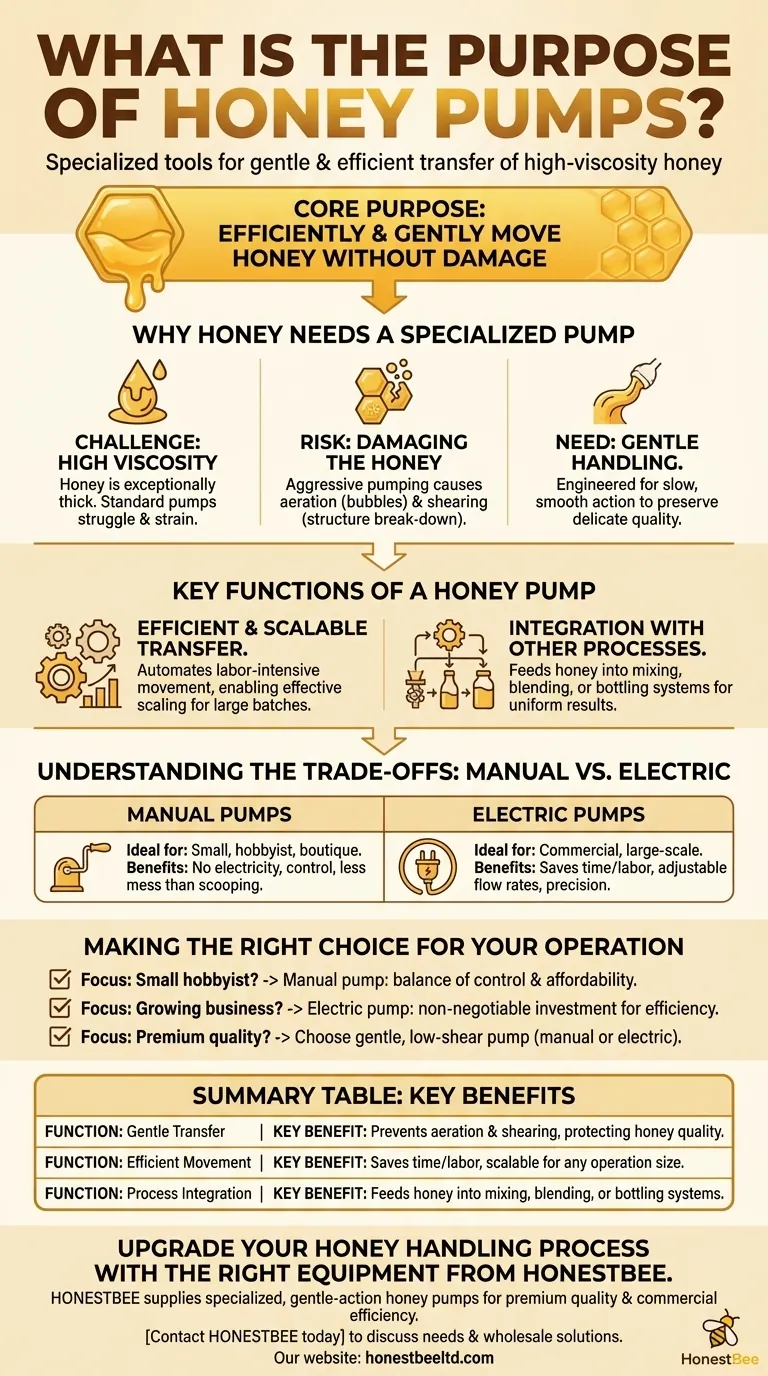

At its core, a honey pump is a specialized tool designed to move honey. Its purpose is to efficiently and gently transfer high-viscosity honey from an extractor or holding tank into storage containers or bottling systems without damaging its delicate structure or quality.

The true purpose of a honey pump isn't just to move honey, but to protect its quality during transfer. Standard pumps can damage honey, while a proper honey pump improves efficiency while preserving the product's integrity.

Why Honey Needs a Specialized Pump

Honey is a unique fluid, and handling it requires specific equipment. Using a generic water or chemical pump would be a significant mistake that compromises the final product.

The Challenge of High Viscosity

Honey is exceptionally thick, or viscous. Standard pumps are not designed to handle this consistency and would struggle to move it, leading to equipment strain and inefficient transfer.

The Risk of Damaging the Honey

Aggressive pumping introduces air bubbles (aeration) and can physically break down the honey's natural structure (shearing). This damages its texture, flavor, and overall quality, which is a critical concern for any producer.

The Need for Gentle Handling

A honey pump is engineered for slow, smooth, and gentle action. This ensures the honey flows without being whipped or agitated, preserving the delicate qualities that make it a premium product.

Key Functions of a Honey Pump

Beyond simple movement, a honey pump serves several critical roles in a beekeeping or honey-packing operation, directly impacting both efficiency and product quality.

Efficient and Scalable Transfer

The most obvious function is saving labor. A pump automates the physically demanding process of moving large quantities of honey, allowing operations to scale effectively from small to large batches.

Integration with Other Processes

Pumps are often a crucial component in a larger processing line. They can feed honey into systems that perform mixing, blending, or moisture removal, ensuring a consistent flow for uniform results.

Understanding the Trade-offs: Manual vs. Electric

The primary decision for a producer is choosing between a manual and an electric pump, a choice that hinges on the scale of the operation.

Manual Pumps

These are ideal for small, hobbyist, or boutique operations. They do not require electricity and provide a significant upgrade over scooping or pouring by hand, offering more control and less mess.

Electric Pumps

For any commercial or large-scale operation, an electric pump is essential. It saves immense time and labor, and many models feature adjustable flow rates to handle different volumes and tasks with precision.

Making the Right Choice for Your Operation

Selecting the right pump is a strategic decision based on your specific goals for efficiency and quality.

- If your primary focus is a small hobbyist operation: A manual pump provides an excellent balance of control and affordability without requiring a major investment.

- If your primary focus is growing your business: An electric pump is a non-negotiable investment that directly translates to time and labor savings.

- If your primary focus is maintaining premium honey quality: Choose a pump specifically designed for gentle, low-shear action, regardless of whether it is manual or electric.

Ultimately, investing in the right honey pump is a decision that protects both the integrity of your product and the efficiency of your workflow.

Summary Table:

| Function | Key Benefit |

|---|---|

| Gentle Transfer | Prevents aeration and shearing, protecting honey quality. |

| Efficient Movement | Saves time and labor, scalable for any operation size. |

| Process Integration | Feeds honey into mixing, blending, or bottling systems. |

Upgrade your honey handling process with the right equipment from HONESTBEE.

Whether you're a commercial apiary or a beekeeping equipment distributor, using the wrong pump can damage your product and hurt your bottom line. HONESTBEE supplies the specialized, gentle-action honey pumps you need to protect your honey's premium quality while dramatically improving your operational efficiency.

Contact HONESTBEE today to discuss your specific needs and discover our wholesale-focused solutions for commercial-scale beekeeping.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Professional Honey Storage Tank with Agitation System

- Professional Honey Filter with Tripod Support Stand

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What is the function of a vacuum suction pump in the harvesting of stingless bee honey? Optimize Your Colony's Yield

- What voltage options are available for stainless steel screw honey pumps? Choose the Right Power for Your Scale

- What advantages do specialized Suction Pumps offer compared to traditional methods? Optimize Royal Jelly Extraction

- What are the types of honey pumps? Choose the Right Pump for Your Apiary

- What are the advantages of using an electric vacuum pump for Melipona subnitida honey? Precision Harvesting Solutions

- What is the role of a portable electric vacuum pump in stingless bee honey collection for palynological analysis?

- What is a filling pump? The Essential Guide for Accurate Liquid Packaging

- What types of pumps are available for honey processing? Choose the Right Pump to Protect Honey Quality