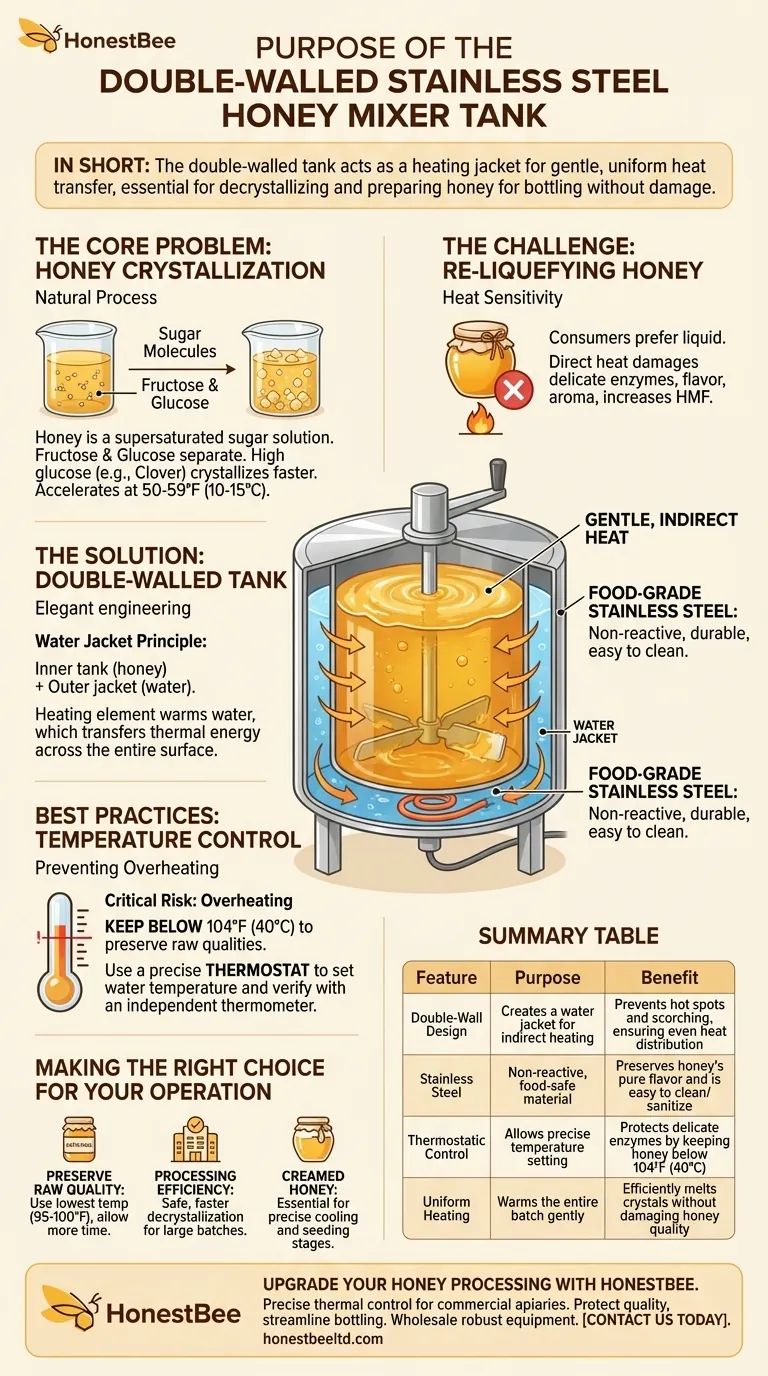

In short, the double-walled stainless steel tank in a honey mixer serves as a heating jacket. This design provides critical thermal control, allowing you to gently and evenly heat the honey, which is essential for efficiently melting crystals and preparing the honey for bottling without damaging its quality.

A double-walled tank isn't just a container; it's a purpose-built tool for thermal management. Its primary function is to reverse the natural process of crystallization by applying gentle, indirect heat, thereby protecting the honey's delicate enzymes, flavor, and aroma.

The Core Problem: Honey Crystallization

To understand the equipment, we must first understand the material. Honey is a supersaturated sugar solution, and crystallization is a completely natural and expected process.

Why Honey Crystallizes

Honey is primarily composed of two sugars: fructose and glucose. Over time, the glucose tends to separate from the water and form small crystals.

The speed of crystallization depends on the honey's floral source. Honeys high in glucose (like clover or dandelion) crystallize faster than those high in fructose (like acacia or tupelo). Temperature also plays a key role, with crystallization accelerating between 50-59°F (10-15°C).

The Challenge of Re-liquefying Honey

While crystallization is natural, most consumers prefer liquid honey. The challenge for a processor is to re-liquefy the honey without damaging it.

Honey is extremely sensitive to heat. Applying direct or excessive heat can destroy its beneficial enzymes, darken its color, and alter its delicate flavor profile. It can also increase the levels of Hydroxymethylfurfural (HMF), an indicator of heat damage.

How the Double-Walled Tank Solves This

The double-walled tank is an elegant engineering solution to the problem of applying heat gently and uniformly.

The "Water Jacket" Principle

The design features an inner tank that holds the honey and an outer tank that creates a sealed gap, or "jacket," around it. This jacket is filled with a heat-transfer medium, typically water.

An electric heating element warms the water in the jacket. The heated water then transfers its thermal energy evenly across the entire surface of the inner tank.

Gentle and Even Heat Distribution

This indirect heating method is far superior to applying heat directly to the bottom of a single-walled tank. It eliminates "hot spots" that would scorch and damage the honey.

The large surface area ensures the entire batch of honey is warmed slowly and uniformly, allowing crystals to dissolve gently while the mixer's paddles keep the liquid circulating.

The Role of Stainless Steel

Food-grade stainless steel is the material of choice for this application. It is non-reactive, meaning it will not impart any flavors to the honey. It's also durable and extremely easy to clean and sanitize, which is critical for food safety compliance.

Understanding the Trade-offs and Best Practices

While a heated tank is a powerful tool, its effectiveness depends entirely on proper operation. The goal is always to use the minimum amount of heat necessary.

The Critical Risk of Overheating

The single biggest mistake is overheating the honey. Keeping the honey below 104°F (40°C) is a widely accepted best practice for preserving its raw qualities.

Exceeding this temperature, especially for prolonged periods, can degrade the honey's quality, diminish its health benefits, and fundamentally change its taste.

The Need for Precise Temperature Control

A quality honey mixer will include a reliable thermostat. This allows the operator to set and maintain a precise water temperature in the jacket.

Never rely on guesswork. Use the thermostat and an independent thermometer to verify the honey's temperature throughout the process to ensure you remain within the safe zone.

Making the Right Choice for Your Operation

How you use a double-walled mixer should align with your specific processing goals.

- If your primary focus is preserving artisanal or raw honey quality: Use the lowest possible temperature setting (e.g., 95-100°F or 35-38°C) and allow more time for decrystallization.

- If your primary focus is commercial processing efficiency: The jacket allows you to safely decrystallize large batches much faster than air-warming methods, ensuring a consistent product for bottling.

- If your primary focus is creating creamed honey: A double-walled tank is essential for precisely controlling the cooling and seeding stages of the creaming process.

Ultimately, the double-walled tank gives you the control necessary to manage honey's natural state without compromising its integrity.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Double-Wall Design | Creates a water jacket for indirect heating | Prevents hot spots and scorching, ensuring even heat distribution |

| Stainless Steel | Non-reactive, food-safe material | Preserves honey's pure flavor and is easy to clean/sanitize |

| Thermostatic Control | Allows precise temperature setting | Protects delicate enzymes by keeping honey below 104°F (40°C) |

| Uniform Heating | Warms the entire batch gently | Efficiently melts crystals without damaging honey quality |

Upgrade Your Honey Processing with HONESTBEE

For commercial apiaries and equipment distributors, precise thermal control is not a luxury—it's a necessity for product quality and operational efficiency. The right honey mixer with a double-walled tank protects your product's value and streamlines your bottling line.

HONESTBEE supplies robust, commercial-grade honey processing equipment designed for high-volume operations. Our wholesale-focused model ensures you get the reliable machinery you need to maintain the integrity of your honey, batch after batch.

Let's discuss your specific needs. Contact our equipment specialists today to find the perfect honey mixer solution for your business.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Uncapping Tank with Stand and Strainer

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Honey Storage Tank with Lid for Honey

People Also Ask

- How do honey heating tanks ensure hygiene and sanitation? A Guide to Food-Grade Design

- Why is industrial-grade constant temperature heating equipment essential for the detoxification processing of specialty honey? Ensure Consumer Safety

- In what ways does a honey heating tank improve efficiency and save time? Master Viscosity for Faster Production

- What is the primary function of a honey heating tank? Master Your Honey Processing with Precision Control

- What are the benefits of precise temperature control in honey heating tanks? Preserve Quality and Efficiency