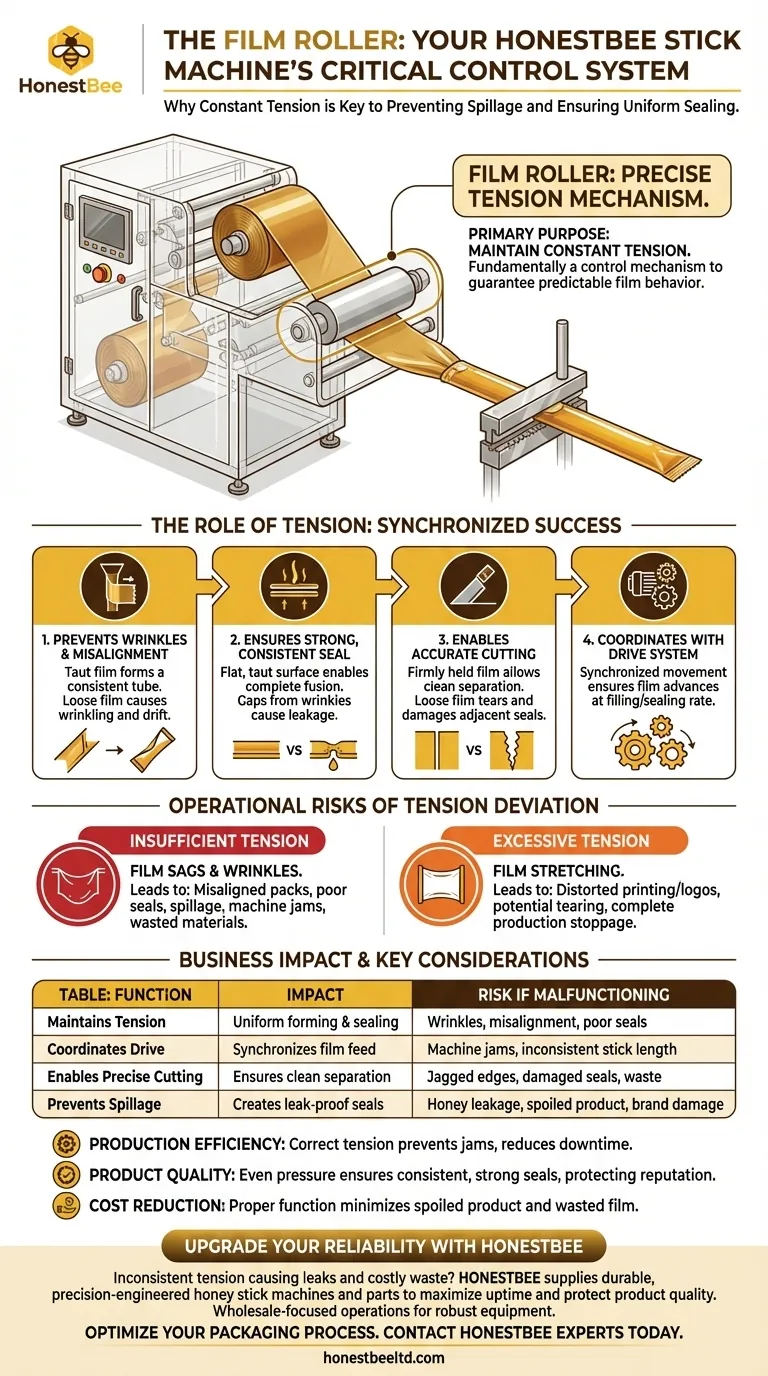

The primary purpose of the film roller in a honey stick machine is to maintain precise and constant tension on the packaging film as it moves through the system. This control is not a minor detail; it is the single most important factor in preventing product spillage and ensuring each honey stick is sealed correctly and uniformly.

The film roller is fundamentally a control mechanism. Its job is to guarantee the packaging film behaves predictably, allowing the forming, filling, and sealing components to work without failure. Without proper tension, the entire packaging process becomes unreliable and prone to costly errors.

The Role of Tension in the Packaging Process

A honey stick machine is a system of synchronized actions. The film roller's ability to manage tension is what allows the other components to perform their jobs effectively.

Preventing Wrinkles and Misalignment

If the packaging film is loose, it will inevitably wrinkle or drift from side to side as it is pulled through the machine. This prevents the forming tube from shaping the film into a consistent, uniform tube, which is the first step in creating a viable stick pack.

Ensuring a Strong, Consistent Seal

The sealing bars apply heat and pressure to fuse the film together. This process requires a perfectly flat and taut surface. Wrinkles or slack in the film create gaps and uneven surfaces, resulting in weak points or incomplete seals that lead directly to honey leakage.

Enabling Accurate Cutting

After a stick is filled and sealed, the cutter must make a clean separation. The film roller holds the film strip firmly in place, allowing the blade to slice cleanly and precisely. A loose film can bunch up or tear, creating jagged edges and potentially damaging the seal of the adjacent stick.

Coordinating with the Drive System

The film roller does not work in isolation. It is driven by the machine's motor, which converts electrical power into the mechanical motion needed to pull the film. This synchronized movement ensures the film advances at the exact same rate as the filling and sealing cycles.

Understanding the Operational Risks

The correct functioning of the film roller is critical. Any deviation from the optimal tension introduces immediate problems into the production line.

The Problem of Insufficient Tension

This is the most common failure point. Too little tension causes the film to sag and wrinkle, leading directly to misaligned packs, poor seals, and product spillage. It is a primary cause of machine jams and wasted materials.

The Risk of Excessive Tension

While less common, applying too much tension is also detrimental. It can stretch the packaging film, distorting any printing or logos. In more extreme cases, it can cause the film to tear, leading to a complete stoppage of the production line.

Key Considerations for Your Operation

Understanding the film roller's function translates directly to better operational outcomes and product quality.

- If your primary focus is production efficiency: Ensure the film roller's tension is correctly calibrated for your specific film type to prevent jams and spillage, which are major sources of downtime.

- If your primary focus is product quality: Regularly inspect the rollers for wear and tear to confirm they provide even pressure, creating consistently strong seals that prevent leaks and protect your brand's reputation.

- If your primary focus is cost reduction: Recognize that proper roller function directly reduces waste by minimizing spoiled product (honey) and discarded packaging film from failed seals.

By viewing the film roller as a critical control system, not just a simple part, you can ensure a more reliable and profitable packaging operation.

Summary Table:

| Function | Impact on Operation | Risk if Malfunctioning |

|---|---|---|

| Maintains Film Tension | Enables uniform forming and sealing | Wrinkles, misalignment, poor seals |

| Coordinates with Drive System | Synchronizes film feed with filling/sealing | Machine jams, inconsistent stick length |

| Enables Precise Cutting | Ensures clean separation of sticks | Jagged edges, damaged seals, product waste |

| Prevents Spillage | Creates strong, leak-proof seals | Honey leakage, spoiled product, brand damage |

Upgrade Your Honey Stick Packaging Reliability with HONESTBEE

Is inconsistent film tension causing leaks, jams, and costly waste in your operation? The film roller is a critical component, and its performance depends on the quality of the entire machine.

HONESTBEE supplies durable, precision-engineered honey stick machines and replacement parts to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get robust equipment that maximizes your packaging line's uptime and protects your product quality.

Let's optimize your packaging process. Contact our experts today to discuss your needs and discover how our solutions can enhance your efficiency and profitability.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why has the small bag honey packaging machine been favored by manufacturers? Unlock Efficiency & Quality

- What are the key advantages of using a honey stick machine in production? Optimize Your Beekeeping Business

- What is the role of a high-precision honey filling machine? Boost Your Retail Packaging Efficiency and Compliance

- What is the purpose of a shaped honey stick machine? Boost Brand Appeal & Sales

- What are the advantages of a honey filling machine with good maintenance and support? Maximize Uptime & Protect Your Investment

- What is the purpose of using precision viscometers in honey filling design? Optimize Flow & Preserve Honey Quality

- What role does automated honey-filling machinery play in international market standards for honey purity and hygiene?

- How do automatic honey-filling machines ensure market competitiveness? Elevate Your Brand and Profitability