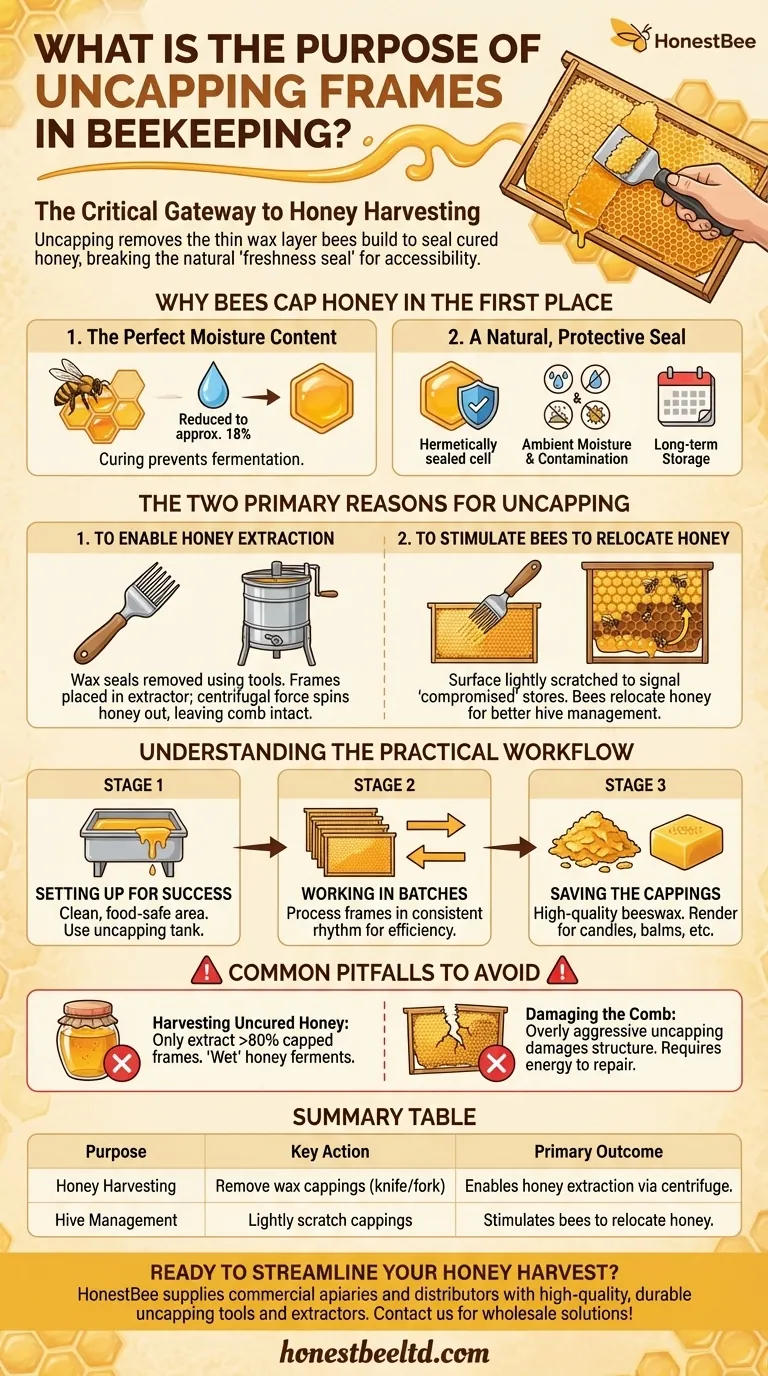

In beekeeping, uncapping frames is the essential step of removing the thin wax layer that bees build to seal their finished honey. This process is the critical gateway to harvesting, as it exposes the honey within the comb's hexagonal cells, allowing it to be extracted. Without uncapping, the honey would remain locked inside the comb.

The core purpose of uncapping is to break the bees' natural "freshness seal" on cured honey. Whether for harvesting or for internal hive management, this action is necessary to make the honey accessible for removal from the comb.

Why Bees Cap Honey in the First Place

To understand uncapping, you must first understand the purpose of the cappings themselves. They are a sign of quality and a critical part of the bees' food preservation strategy.

The Perfect Moisture Content

Bees are meticulous. They only cap honey cells after they have reduced the nectar's water content to approximately 18%. This process, known as "curing," prevents the honey from fermenting and spoiling.

A Natural, Protective Seal

The wax capping acts as a hermetic seal. It protects the cured honey from absorbing ambient moisture and from contamination, ensuring it remains stable for long-term storage as the colony's winter food supply. For the beekeeper, these cappings are a clear visual indicator that the honey is ready for harvest.

The Two Primary Reasons for Uncapping

While uncapping is most famously associated with honey harvesting, it also serves a secondary, more strategic purpose for managing the hive.

1. To Enable Honey Extraction

This is the most common reason. To get the honey out, the wax seals must be removed. Using a tool like an uncapping fork or a heated knife, the beekeeper slices or scrapes off this top layer of wax.

Once uncapped, the frame is placed in a honey extractor. This device uses centrifugal force to spin the honey out of the open cells without destroying the underlying comb structure, which can then be returned to the bees to refill.

2. To Stimulate Bees to Relocate Honey

A beekeeper might want bees to move honey from one part of the hive to another. For instance, they may want to clear a brood box of honey to give the queen more room to lay eggs.

In this scenario, instead of fully removing the cappings, the beekeeper will lightly "scratch" their surface with an uncapping fork. This damage signals to the ever-tidy bees that the honey stores are compromised. They will then uncap the cells themselves, consume the honey, and move it to a more "secure" location, typically higher up in the hive's honey supers.

Understanding the Practical Workflow

An efficient uncapping process makes the entire harvest experience smoother, cleaner, and more productive.

Setting Up for Success

The process is inherently sticky. Designate a clean, food-safe area for the task. Many beekeepers use a dedicated uncapping tank, which holds the frame and collects the dripping honey and wax cappings.

Working in Batches

Organize your frames and work through them in a consistent rhythm. Uncapping a batch of frames before moving them to the extractor is far more efficient than processing one frame at a time from start to finish. This batch-processing approach streamlines the workflow and simplifies cleanup.

Saving the Cappings

Don't discard the wax cappings. They are saturated with honey and consist of pure, high-quality beeswax. This "cappings wax" is highly prized and can be washed, melted, and rendered into clean blocks of beeswax for making candles, balms, or other products.

Common Pitfalls to Avoid

Uncapping is straightforward, but mistakes can impact your honey quality and your bees' workload.

Harvesting Uncured Honey

Only uncap and extract frames that are at least 80% capped. Extracting uncapped, "wet" honey means its moisture content is too high. This honey will eventually ferment and spoil.

Damaging the Comb

While speed is good, being overly aggressive can damage the structure of the comb itself. The goal is to remove only the thin capping, leaving the underlying hexagonal cells intact. Damaged combs require significant energy and resources for the bees to repair.

Making the Right Choice for Your Goal

Your approach to uncapping depends entirely on your objective.

- If your primary focus is harvesting honey: Use a knife or fork to cleanly remove the entire surface of the cappings to ensure complete extraction.

- If your primary focus is managing hive space: Lightly scratch the cappings to encourage the bees to relocate the honey themselves.

- If your primary focus is efficiency and colony health: Only uncap fully cured honey and handle the frames carefully to preserve the comb for the bees to reuse.

Ultimately, uncapping is the deliberate act that signals the transition from colony storage to human harvest, making it a pivotal moment in the beekeeper's year.

Summary Table:

| Purpose of Uncapping | Key Action | Primary Outcome |

|---|---|---|

| Honey Harvesting | Remove wax cappings with a knife or fork. | Enables honey extraction via centrifuge. |

| Hive Management | Lightly scratch cappings to signal bees. | Stimulates bees to relocate honey within the hive. |

Ready to streamline your honey harvest? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, durable uncapping tools and extractors needed for maximum efficiency. Our wholesale-focused operations ensure you get the reliable equipment your business depends on. Contact us today to discuss your needs and see how we can support your success!

Visual Guide

Related Products

- Stainless Steel Pivoting Honey Uncapping Fork with Plastic Handle

- All-Stainless Steel Pivoting Honey Uncapping Fork for Beekeeping

- Professional Stainless Steel Double-Sided Honey Uncapping Knife

- Professional Bent Tine Honey Uncapping Fork with Ergonomic Grip

- Adjustable Stainless Steel Honey Uncapping Fork with Scraper for Beekeeping

People Also Ask

- What is the use of an uncapping fork? A Precision Tool for Hive Management and Honey Harvesting

- What are the advantages of an uncapping fork? Achieve Precision Honey Harvesting for Your Apiary

- What are the common methods used by small-scale beekeepers to uncap honey frames?

- Why is a specialized honey harvest knife essential? Protect Hive Health and Maximize Honey Extraction Efficiency

- Why is the use of Uncapping Tools considered an essential step prior to the honey extraction process? Unlock Your Harvest