In short, foundation is a beekeeper's tool for control. It is a thin sheet, typically made of plastic or beeswax, that is imprinted with a hexagonal honeycomb pattern. This sheet is inserted into a frame, providing bees with a clear guide and template to build their wax comb, ensuring it is straight, orderly, and contained entirely within the removable frame.

The fundamental purpose of foundation is to impose order on the hive's natural construction. This control is not for the bees' sake, but for the beekeeper's, making hive inspections manageable, protecting the colony from damage during those inspections, and encouraging a productive hive structure.

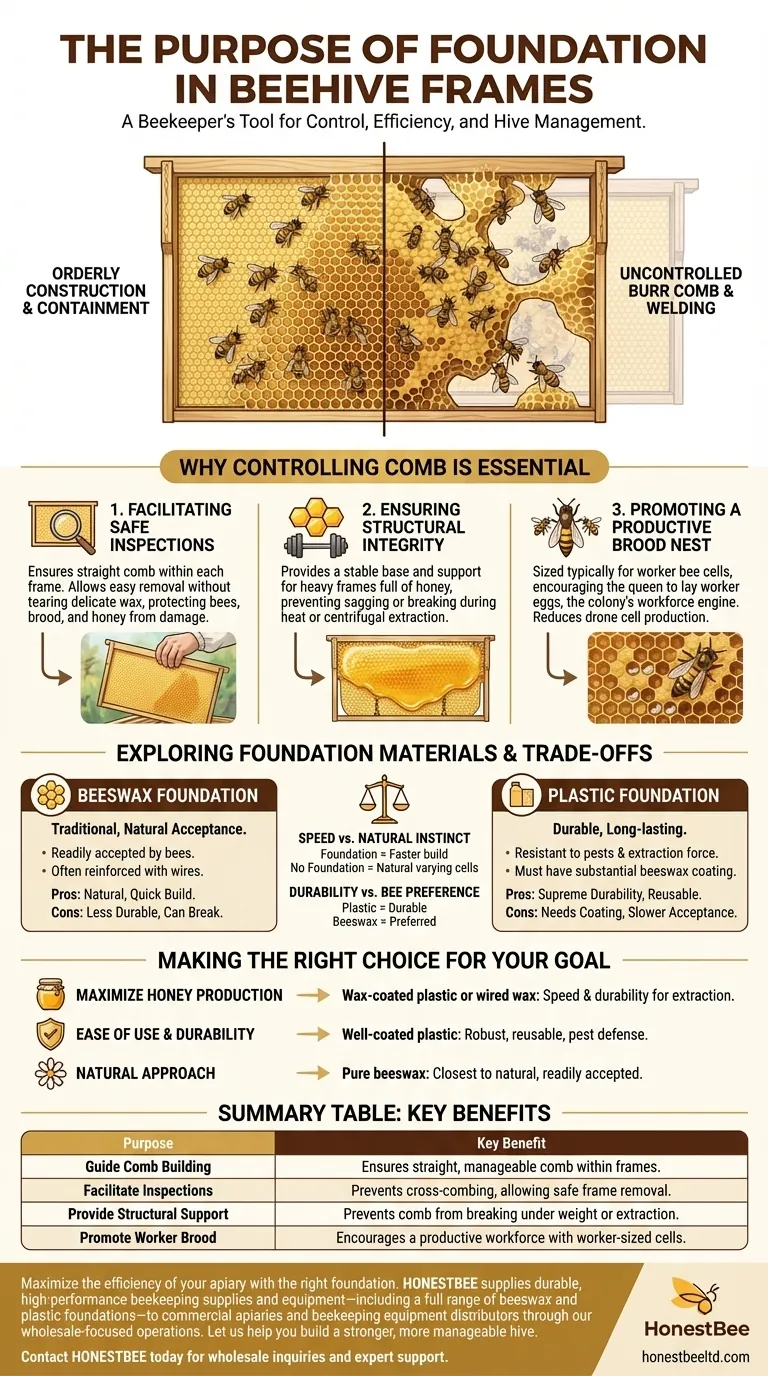

Why Controlling Comb Construction is Essential

Wild honey bees build comb wherever they see fit. In a modern beehive, this uncontrolled building, known as burr comb, would weld frames together, making management impossible. Foundation solves this by directing the bees' architectural instincts.

Facilitating Safe Hive Inspections

The primary benefit of foundation is manageability. By ensuring bees build straight comb within each frame, the beekeeper can easily remove, inspect, and replace individual frames.

Without this guidance, frames would be cross-combed and stuck together. Pulling them apart would tear the delicate wax, destroying brood, spilling honey, and crushing bees, which is highly disruptive and stressful for the colony.

Ensuring Structural Integrity

Foundation provides a stable base for the bees' wax construction. A frame full of honey can be incredibly heavy, and the foundation adds crucial support to prevent the comb from sagging or breaking.

This is especially important in warmer climates or during the honey extraction process, where the centrifugal force would easily destroy unsupported comb.

Promoting a Productive Brood Nest

The hexagonal pattern imprinted on foundation is typically sized for worker bee cells. This encourages the queen to lay eggs that will develop into female worker bees—the engine of the hive.

While bees will still build some larger drone cells, the foundation template helps ensure the vast majority of the brood nest is dedicated to building the colony's workforce.

Exploring Foundation Materials

The material you choose has a direct impact on durability, cost, and how readily your bees will accept it.

Beeswax Foundation

This is the most traditional option. Beeswax sheets, often reinforced with internal wires for strength, are readily accepted by bees since it's their natural building material.

Plastic Foundation

Valued for its supreme durability and longevity. Plastic foundation is resistant to pests like wax moths and will not break during honey extraction.

However, it is critical that plastic foundation has a substantial coating of beeswax. Bees will not build on bare plastic, so a quality wax coating is non-negotiable for it to be successful.

Understanding the Trade-offs

Choosing to use foundation is a strategic decision that comes with clear benefits and considerations.

Speed vs. Natural Instinct

Foundation gives the bees a massive head start. Drawing out fresh comb is an energy-intensive process for bees, and providing a template allows them to build much faster.

The trade-off is that it removes their ability to build comb according to their own instincts, which includes varying cell sizes as they see fit.

Durability vs. Bee Preference

While not universally true, many beekeepers observe that bees are quicker to build on pure beeswax foundation than on plastic.

The choice comes down to balancing the bees' potential preference against the clear durability and reusability benefits of plastic, especially for large-scale operations.

Making the Right Choice for Your Goal

Your goals as a beekeeper will determine the best type of foundation for your hives.

- If your primary focus is maximizing honey production: Wax-coated plastic or wired wax foundation provides the speed and durability needed for efficient honey extraction and quick turnaround.

- If your primary focus is ease of use and long-term durability: Well-coated plastic foundation is robust, reusable, and offers the best defense against pests and breakage.

- If your primary focus is a more natural approach: Pure beeswax foundation is the closest manufactured option to what bees create themselves, and it is readily accepted by the colony.

Ultimately, using foundation is a foundational technique in modern beekeeping that exchanges the bees' architectural freedom for critical hive stability, safety, and manageability.

Summary Table:

| Purpose | Key Benefit |

|---|---|

| Guide Comb Building | Ensures straight, manageable comb within frames. |

| Facilitate Inspections | Prevents cross-combing, allowing safe frame removal. |

| Provide Structural Support | Prevents comb from breaking under weight or during extraction. |

| Promote Worker Brood | Encourages a productive workforce with worker-sized cell patterns. |

Maximize the efficiency and productivity of your apiary with the right foundation. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment—including a full range of beeswax and plastic foundations—to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. Let us help you build a stronger, more manageable hive. Contact HONESTBEE today for wholesale inquiries and expert support.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Food Grade Plastic bee Foundation for Bee Frames

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- Why is wax foundation used as a critical production consumable? Boost Honey Yields and Hive Efficiency

- What is the significance of analyzing beeswax when monitoring substances? Map Chronic Risks in Your Beehive

- What is the primary function of foundation in beehives? Boost Hive Stability and Honey Production

- What is the primary function of embossed wax? Boost Bee Colony Induction & Speed Up Hive Colonization

- How do high-quality comb foundations contribute to honeybee colony productivity? Maximize Your Spring Yield

- What is the purpose of installing wax foundations in beeswax studies? Ensure Scientific Accuracy and Data Integrity

- Why are pest control treatments and drying processes necessary for crude beeswax? Protect Your Raw Material Value

- What are the primary advantages of using natural bee products like beeswax? Enhance Hive Purity and Yield