At its core, modern honey processing equipment is designed to perform two primary functions: purifying the honey and ensuring its long-term stability. A complete system handles everything from initial extraction and the removal of impurities to blending batches for consistency and reducing water content to prevent fermentation, all within a single, integrated plant.

The purpose of honey processing equipment is not to alter the honey, but to refine and stabilize it. Investing in quality equipment is about maximizing production efficiency and guaranteeing the purity, safety, and consistency required to build a trusted, market-ready product.

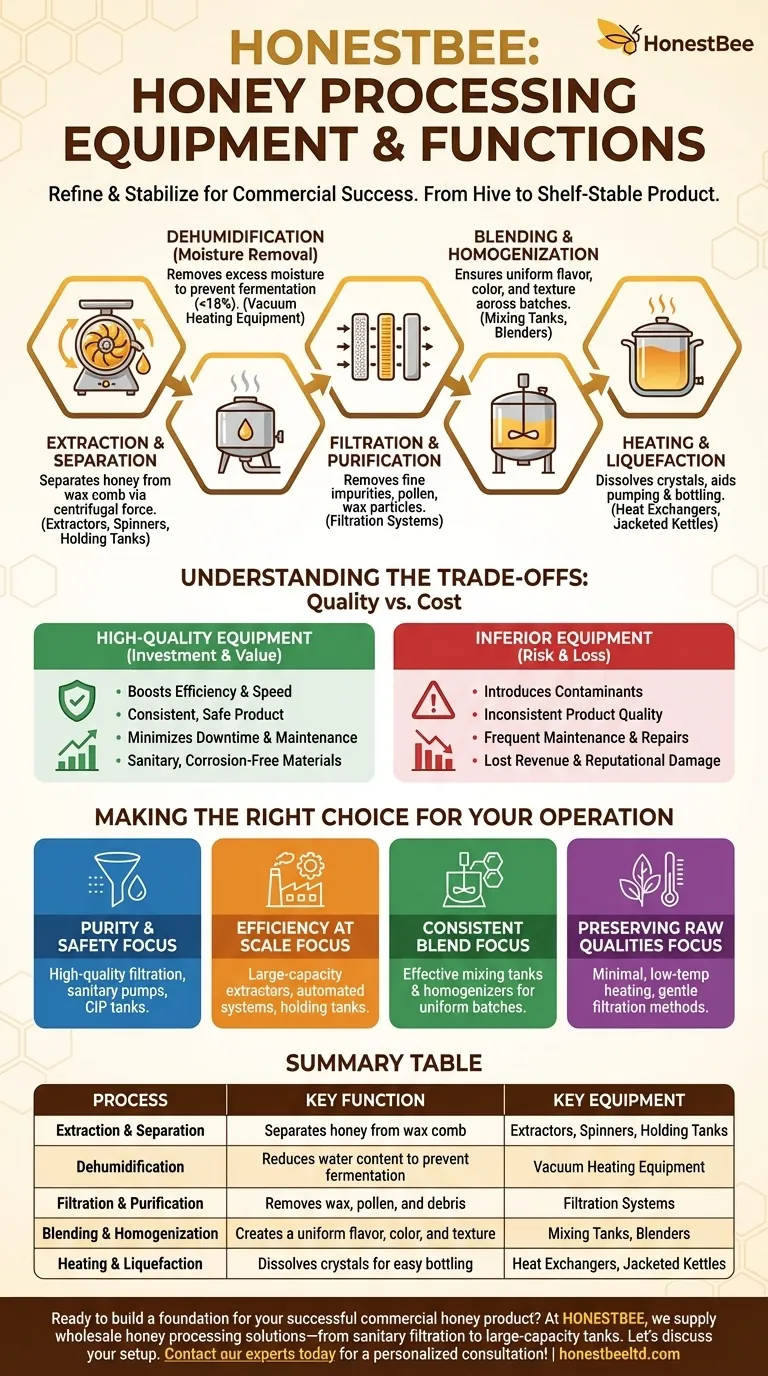

Core Honey Processing Functions

To turn raw honey from the hive into a shelf-stable product, several key processes are required. Quality equipment standardizes these steps, reducing manual labor and ensuring a reliable outcome.

Extraction and Separation

The first step is separating the liquid honey from the beeswax comb. Specialized extractors and spinners use centrifugal force to accomplish this efficiently without damaging the comb, which can often be reused. Holding tanks are then used for the initial collection.

Dehumidification (Moisture Removal)

Raw honey often contains excess water, which can lead to fermentation and spoilage. Processing plants use equipment to gently heat the honey, often under vacuum, to remove excess moisture. This lowers the water content to a stable level (typically below 18%), preserving the honey indefinitely.

Filtration and Purification

To achieve a clear and pure final product, honey must be filtered. This process removes fine impurities such as wax particles, pollen, and other debris from the hive. Quality filtration systems are designed to do this without removing the beneficial natural qualities of the honey itself.

Blending and Homogenization

For commercial producers, consistency is key. Large mixing and blending tanks are used to homogenize honey from different batches or floral sources. This ensures a uniform flavor, color, and texture across the entire production run, which is critical for brand reliability.

Heating and Liquefaction

Honey naturally crystallizes over time. Processing equipment includes heat exchangers or jacketed kettles that apply controlled, gentle heat. This process, known as liquefaction, dissolves sugar crystals and can also be a step in pasteurization, making the honey easier to pump and bottle.

Understanding the Trade-offs: Quality vs. Cost

Investing in processing equipment involves a critical decision between upfront cost and long-term value. The quality of your machinery directly impacts your final product and operational health.

The Impact of High-Quality Equipment

Superior equipment made from corrosion-free, sanitary materials ensures product purity and safety. It boosts efficiency, shortens processing times, and produces a consistent product batch after batch. Reliable machinery also minimizes maintenance downtime, leading to higher productivity and greater profitability.

The Risks of Inferior Equipment

Low-cost or poorly designed equipment can introduce contaminants, fail to properly stabilize the honey, and require frequent maintenance. This leads to an inconsistent product, potential safety hazards, and lost revenue due to downtime. In the end, what is saved upfront is often lost through inefficiency and reputational damage.

Making the Right Choice for Your Operation

The ideal equipment configuration depends entirely on your production goals.

- If your primary focus is product purity and safety: Invest in high-quality filtration systems, sanitary pumps and fittings, and effective Clean-in-Place (CIP) tanks.

- If your primary focus is production efficiency at scale: Prioritize large-capacity extractors, holding tanks, and automated systems for moisture removal and bottling.

- If your primary focus is creating a consistent signature blend: Your most critical components will be effective mixing tanks and homogenizers.

- If your primary focus is preserving raw, natural qualities: Select equipment that uses minimal, low-temperature heating and gentle filtration methods.

Ultimately, the right processing equipment is the foundation for transforming high-quality raw honey into a successful commercial product.

Summary Table:

| Process | Key Function | Key Equipment Used |

|---|---|---|

| Extraction & Separation | Separates honey from wax comb | Extractors, Spinners, Holding Tanks |

| Dehumidification | Reduces water content to prevent fermentation | Vacuum Heating Equipment |

| Filtration & Purification | Removes wax, pollen, and debris | Filtration Systems |

| Blending & Homogenization | Creates a uniform flavor, color, and texture | Mixing Tanks, Blenders |

| Heating & Liquefaction | Dissolves crystals for easy bottling | Heat Exchangers, Jacketed Kettles |

Ready to build a foundation for your successful commercial honey product?

At HONESTBEE, we understand that the right equipment is critical for purity, efficiency, and consistency. We supply commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-focused honey processing solutions—from sanitary filtration systems to large-capacity tanks—designed to maximize your production and protect your brand's reputation.

Let's discuss the perfect setup for your operational goals. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What size honey extractor do I need? Match Frame Capacity to Your Hives for Maximum Efficiency

- Which type of honey extractor is generally more durable? Focus on Material & Build Quality for Longevity

- What is the easiest way to extract honey from a honeycomb? A Simple Guide for Beginners

- How to extract honey by hand? A Guide to Crush & Strain vs. Manual Extractors

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently