At its core, a labeling machine is an automated system designed to apply labels to products, containers, or packages with precision and speed. It moves beyond simple adhesion, serving as a critical junction for operational efficiency, regulatory compliance, and brand presentation on the packaging line.

A labeling machine is not merely an operational tool for applying labels; it is a strategic asset. Its primary role is to bridge the gap between production and the marketplace by ensuring every product is efficiently, accurately, and professionally prepared for the consumer.

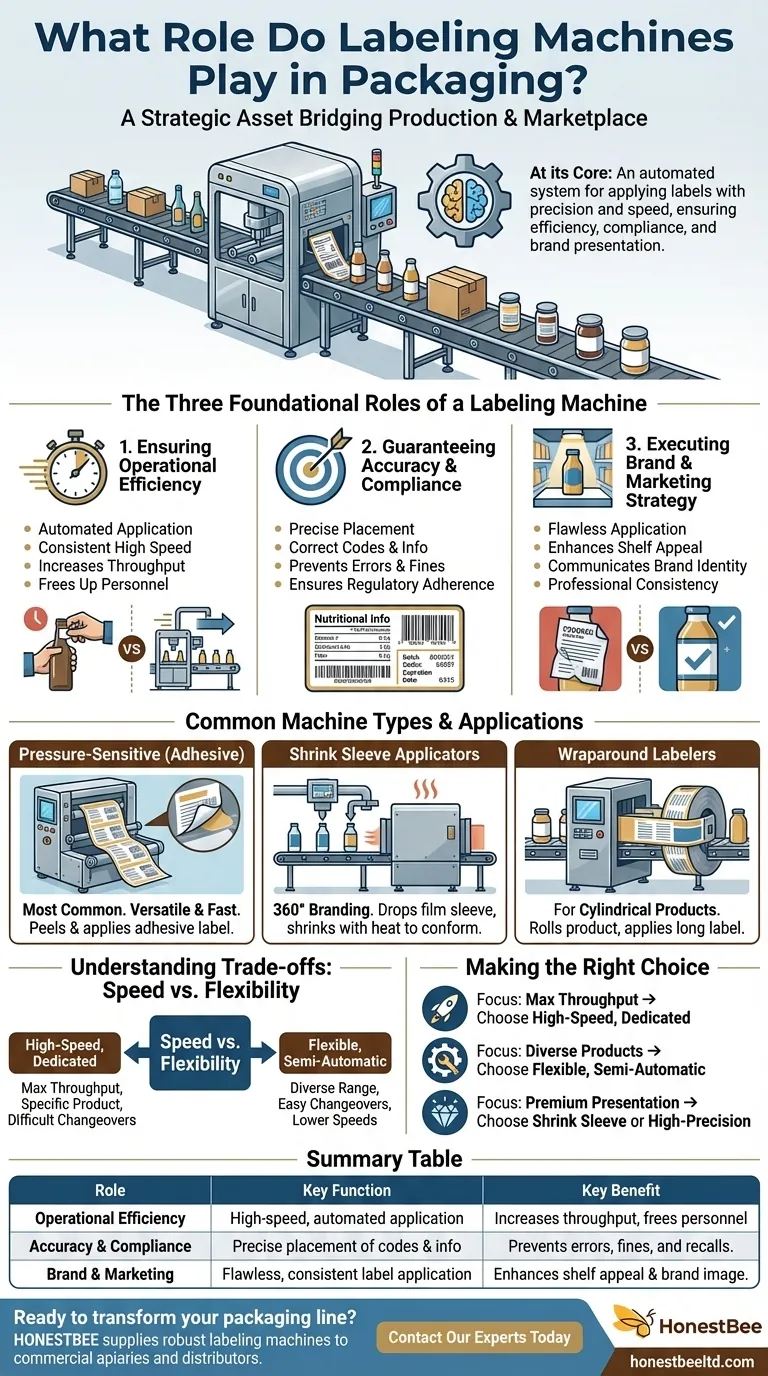

The Three Foundational Roles of a Labeling Machine

A labeling machine performs three distinct but interconnected functions. Understanding each is key to appreciating its impact on your entire operation.

Role 1: Ensuring Operational Efficiency

Manual labeling is a significant bottleneck in any production environment. It is slow, labor-intensive, and prone to inconsistency.

An automated labeling machine solves this by integrating directly into a production line. It applies labels at a consistent, high speed that far surpasses human capability, directly increasing your overall output and throughput.

This automation frees up personnel for higher-value tasks and ensures a predictable, repeatable process, which is the foundation of any scalable operation.

Role 2: Guaranteeing Accuracy and Compliance

Inaccurate labeling is a costly mistake. It can lead to shipping errors, retailer rejection, regulatory fines, or even product recalls.

Labeling machines provide unparalleled accuracy in placement, ensuring that barcodes, nutritional information, batch codes, and expiration dates are placed correctly every single time. This precision is non-negotiable for industries like food and beverage, pharmaceuticals, and cosmetics.

By codifying the application process, the machine removes the risk of human error, acting as your first line of defense in quality control and regulatory adherence.

Role 3: Executing Brand and Marketing Strategy

The label is often the most critical marketing element of your physical product. It communicates brand identity and provides the "shelf appeal" necessary to attract customers.

A poorly applied label—crooked, wrinkled, or bubbled—sends a message of low quality and poor attention to detail.

A labeling machine ensures every label is applied flawlessly, presenting your brand in the best possible light. Whether it's a simple front-and-back application or a full-body shrink sleeve, the machine executes your branding strategy with professional consistency on every single unit.

Common Machine Types and Their Applications

The type of machine you need is directly related to the type of label and product you have.

Pressure-Sensitive (Adhesive) Labelers

These are the most common machines. They work by peeling a pre-printed, adhesive-backed label from a liner roll and applying it to the product with pressure. They are versatile, fast, and suitable for most applications.

Shrink Sleeve Applicators

These machines drop a tube of film (a "sleeve") over a product. The product then passes through a heat tunnel, which shrinks the film to conform perfectly to the container's shape. This allows for 360-degree branding and is popular for uniquely shaped containers.

Wraparound Labelers

Designed specifically for cylindrical products like bottles, cans, and jars, these machines roll the product as a single long label is applied, wrapping it partially or fully around the container.

Understanding the Trade-offs: Speed vs. Flexibility

When selecting a labeling machine, the primary trade-off is often between dedicated speed and operational flexibility.

High-speed, fully integrated machines are built for a specific product and label type. They offer maximum throughput but can be difficult and time-consuming to reconfigure for different product sizes or shapes.

Conversely, more flexible or semi-automatic systems are easier to adjust. While they may not reach the peak speeds of a dedicated machine, their ability to handle a diverse range of products makes them ideal for businesses with smaller batch sizes or varied product lines.

Making the Right Choice for Your Goal

Your choice depends entirely on your primary business objective.

- If your primary focus is maximizing throughput: Invest in a high-speed, dedicated labeling machine designed specifically for your highest-volume product.

- If your primary focus is handling diverse products: Choose a flexible, semi-automatic labeler that allows for quick and easy changeovers between different container sizes and label types.

- If your primary focus is premium brand presentation: Consider a shrink sleeve applicator for full-body graphics or a high-precision pressure-sensitive machine to ensure a flawless finish.

Ultimately, integrating the right labeling machine transforms a simple label from a piece of paper into a powerful tool for operational excellence.

Summary Table:

| Role | Key Function | Key Benefit |

|---|---|---|

| Operational Efficiency | High-speed, automated application | Increases throughput and frees personnel |

| Accuracy & Compliance | Precise placement of codes and info | Prevents errors, fines, and recalls |

| Brand & Marketing | Flawless, consistent label application | Enhances shelf appeal and brand image |

Ready to transform your packaging line? HONESTBEE supplies robust, high-performance labeling machines and equipment to commercial apiaries and beekeeping equipment distributors. Let us help you achieve superior efficiency, accuracy, and brand presentation. Contact our wholesale experts today to find the perfect labeling solution for your operation!

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

People Also Ask

- What decorative options can be used to make honey labels more visually appealing? Elevate Your Premium Packaging

- Why are detailed QR code links considered an important technical method in honey traceability systems? Build Consumer Trust

- How do automated packaging and labeling machines provide a competitive edge for honey? Scale Your Honey Brand Today

- What are the advantages and disadvantages of manually applying honey labels? Expert Comparison for Your Brand

- How does an automatic labeling machine operate? Achieve High-Speed, Precise Product Labeling

- What key functions do high-quality packaging materials serve? Unlock the Commercial Potential of Your Honey

- What are the characteristics and benefits of using an automatic labeling machine for honey products? Boost Your Brand

- What role does a labeling system play in honey quality traceability and brand protection? Secure Your Market Reputation